Italian research agency Enea and Italy-based heterojunction PV manufacturer Enel Green Power are contributing to the development of a pilot line to completely recycle solar modules at the end of their life cycle.

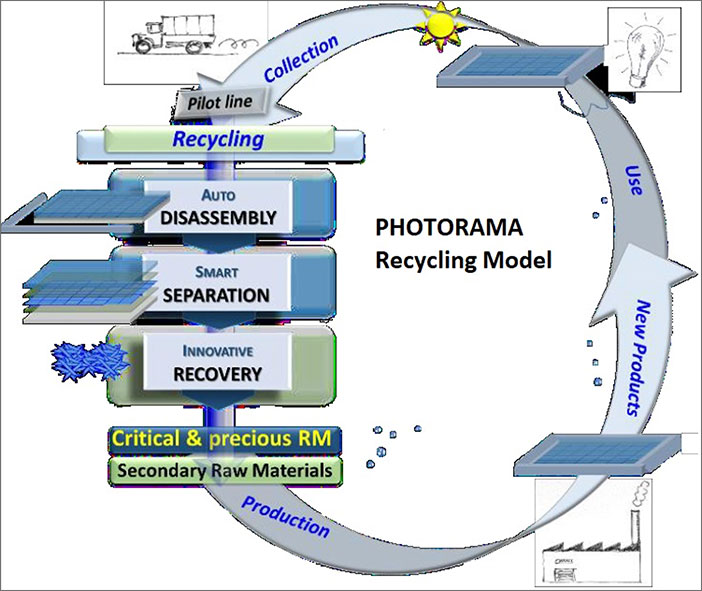

The novel recycling process is being developed the frame of the research project Photorama, which is coordinated by the French Alternative Energies and Atomic Energy Commission (CEA), and is aimed at demonstrating innovative solutions dedicated to the recycling of raw materials from end-of-life PV products while maximizing the recovery rates of raw materials from PV panels compared to conventional technologies and enabling the use of the recycled materials with a circular economy approach for the production of secondary raw materials (SRMs).

The project envisages the construction of a low-emissions pilot line to recover critical and precious metals such as silicon (Si), indium (In), gallium (Ga), silver (Ag). It will then reintroduce them into the production cycle as new materials or new products.

The pilot line will work in three different steps: module auto disassembly, the smart separation of the components, and the innovative recovery of the materials.

“The process starts with a new delamination technique based on a wire diamond technology, developed and patented by the CEA,” Enea researcher Massimo Izzi told pv magazine. “With this technology, it will be possible to separate a module’s glass, backsheet, and cells in a single process, in such a way that the single parts of the module can then be treated individually for the recycling phase.”

Chemical-physical processes based on supercritical fluid (SCF) is another delamination process that will be developed to allow for further high recovery rate material without resorting to the current and inefficient shredding techniques through which the cells, which are the valuable part of the module, end up in a recovery chain of low economic value, the so-called “down-cycling.”

The wire diamond and the SFC techs are used after the recovery of external aluminum, cable and junction box is implemented, enabling the clean separation of glass, solar cells and polymers and providing uncontaminated materials fractions. After the smart separation phase, an innovative extraction process is used to recover a silver fraction of more than 95% with a high purity level from the solar cell. Moreover, the remaining fraction of silicon will be recovered at metallurgic grade.

A subdivision of the pilot line will be dedicated to the recycling of thin-film GIGS modules. The delamination and extraction processes will be based on technologies patented by German technology company Lux Chemtech and will allow high recovery of indium and gallium. The process using biodegradable leachate in CIGS panels will also be developed for the heterojunction technology in which silicon and indium are electrochemically isolated after dissolution.

After the entire recycling process is finished, the unbroken glass will be remastered for direct use in the solar industry, while silver will be converted into conductive inks for screen printing or electrically conductive adhesives to be tested and qualified in PV factories. Silicon will be treated to obtain different purities for use as silicon feedstock in PV manufacturing, or as a sputtering target. Indium will be used in thin-film deposition to be tested and qualified in PV manufacturing. Gallium will be processed to fabricate Cu-Ga or Cu-In-Ga targets used in CIGS-CIS thin-film PV manufacturing.

The pilot line is expected to reach a technology readiness level (TRL) of seven. The TRL measures the maturity of technology components for a system and is based on a scale from one to nine, with nine representing mature technologies for full commercial application. According to Izzi, the pilot line will allow the recovery of the metals from the panels with a degree of purity that has never been achieved before. “It is one of the more advanced and efficient recycling processes in the world,” he said.

The development of the new recycling process will be done in conjunction with testing in a real factory environment. Enel Green Power will provide the modules to be recycled and will use the recycled raw materials in solar cell and module production.

The consortium also includes Spanish PV equipment supplier Mondragon Assembly, Norwegian research entity Sintef, Belgian flat glass processor Maltha, Spanish research company Idener, and Lux Chemtech.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.