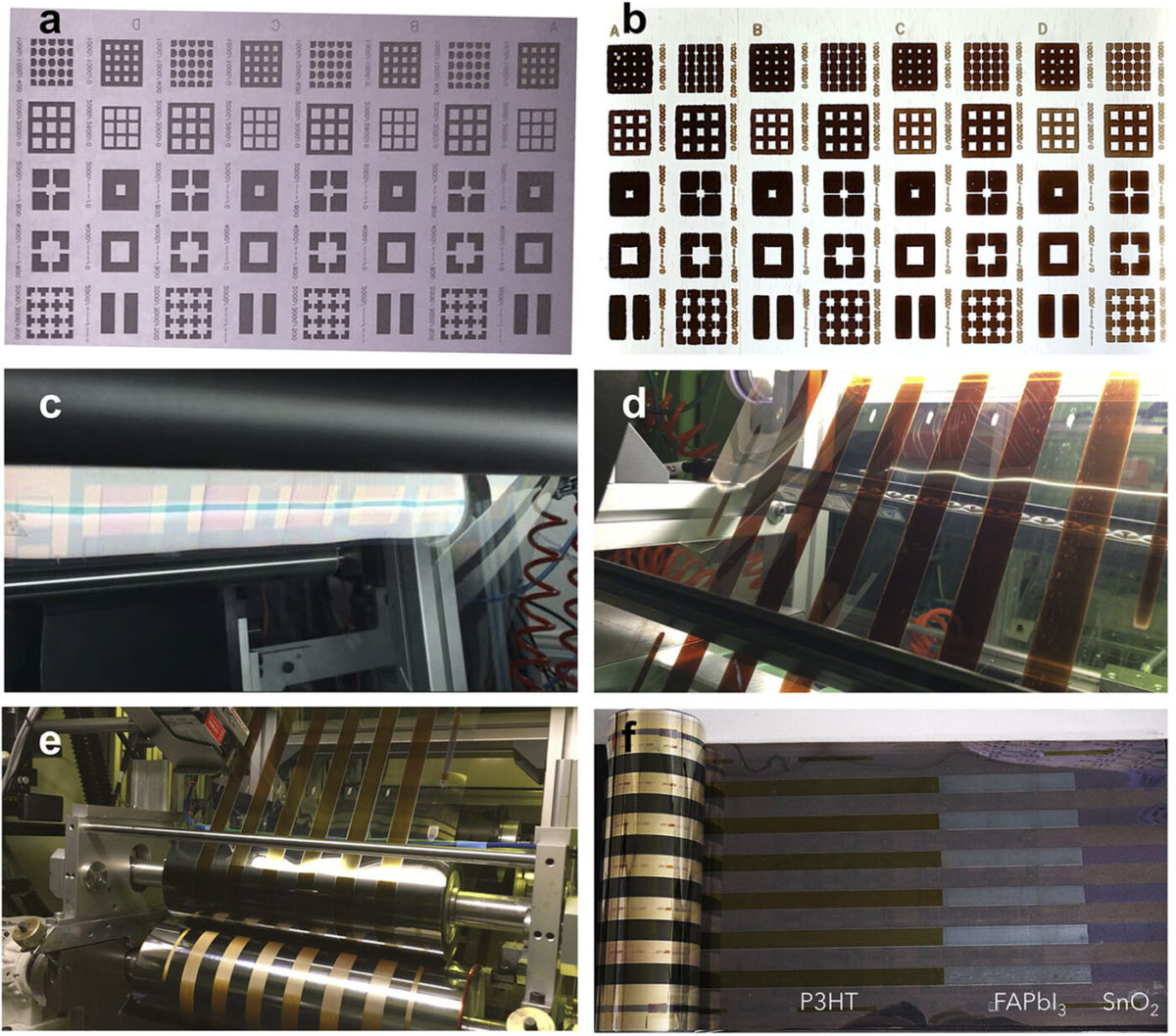

One reason for all hype around perovskite solar cells is their potential to be produced at large scale, low cost and on flexible substrates that could open new applications and opportunities for solar power generation. However, this will depend on the development of suitable solution-based ‘roll-to-roll’ processes, where the cell materials are continuously deposited onto a substrate as it moves between two rolls.

Most of the best-performing perovskite solar cells fabricated to date have been made using spin coating, which isn’t suitable for large surface areas or high-volume manufacturing. Other solution-based processes also struggle to replicate high efficiencies achieved on devices measuring a few centimeters at most to commercially relevant sizes.

Vapor-based deposition processes have achieved good results both for standalone perovskite solar cells and silicon tandem devices, having been used for many years to produce other types of thin-film solar cells. Developing processes to make solution-based perovskite cells at large-scale has proved challenging, but continues to be widely investigated thanks to its low-cost potential.

Roll-to-roll processing

Scientists led by the Korea Research Institute of Chemical Technology looked to evaluate progress in developing such processes, and outline the key challenges that remain. Their work reveals a wide range of potential routes, each with its own set of challenges and potential advantages. Their full evaluation can be found in the paper Roll-to-roll manufacturing toward lab-to-fab-translation of perovskite solar cells, published in APL Materials.

The group outlines a long list of remaining challenges, noting that all should be considered together for the best overall results, when it comes to the effect each stage of processing has on the individual materials involved. “One issue that needs to be carefully investigated is the effect of various factors, such as [roll-to-roll] deposition methods modified from the [sheet-to-sheet] process, on the stability and mechanical durability: applied tension during processing, exerted pressure with the roller, and thermal expansion of layers and substrates,” they explain.

They further note that other cell layers such as the indium-tin oxide commonly used as a transparent electrode would need to be changed or optimized to suit both roll-to-roll processing and flexible applications. Despite the long list of challenges, the group appears optimistic that suitable processes will soon be developed. “By resolving the remaining issues of R2R production,” they conclude, “Perovskite solar cells can be commercialized in the near future via R2R processes, not only for outdoor power generation but also for niche applications, including indoor or portable applications.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.