Perovskite solar cells have long held the promise for high efficiency and low production costs. And as scientists make real progress solving their well-documented challenges with long-term stability, the industry is beginning to picture what large-scale production of this technology could actually look like – either integrated into silicon cell manufacturing as a tandem device, or as a standalone perovskite solar cell.

In India, meanwhile, recent investments point to big plans for a major solar manufacturing hub that will rely on many of the latest technologies. A group of scientists led by the Indian Institute of Technology (IIT) in Mandi, Himachal Pradesh, put these two together to conduct a techno-economic analysis of the opportunity to manufacture perovskite solar cells in their region of the country.

The group carried out the analysis based on a 100 MW production line, manufacturing perovskite solar modules utilizing a carbon-based electrode. This approach is less often seen in research devices, which commonly rely on metal electrodes. IIT states that while carbon electrodes typically achieve lower module efficiency, they can be produced at a lower cost and show an advantage in terms of stability.

Competitive with silicon

Results of the analysis are published in the paper Costing Analysis of Scalable Carbon-Based Perovskite Modules Using Bottom Up Technique, published in Global Challenges. The group calculated two different manufacturing processes – low-temperature and high-temperature processing.

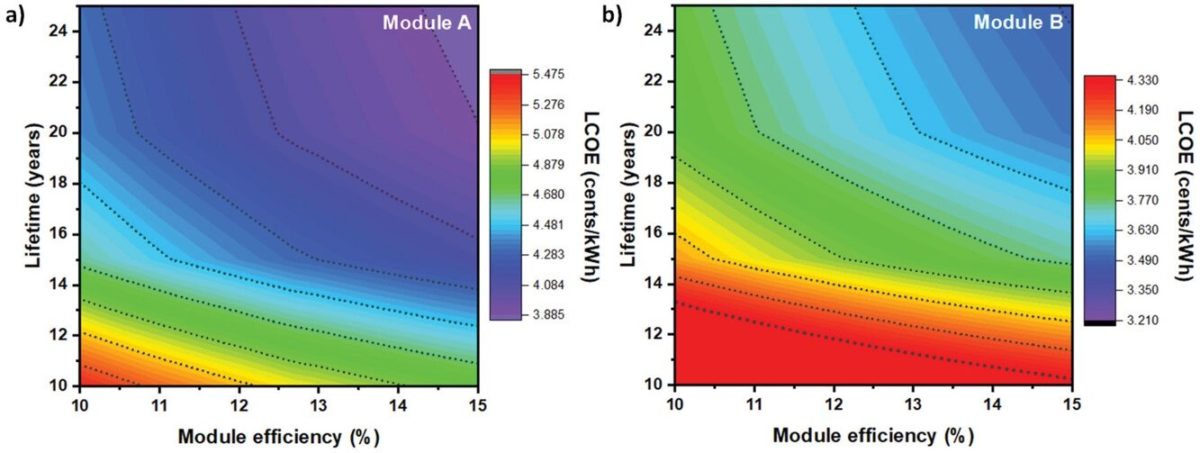

The group finds that for the high-temperature processing route (module A), a manufacturing cost of $0.2106/W could be achieved, and the low-temperature route (module B) could go as low as $0.1548/W. The calculations are based on module efficiencies of 12.77% and 13.57, respectively, which the group says represents 75% of the highest reported lab efficiencies for each technology.

In terms of the final cost of energy, they present calculations for various product lifetimes between 10 and 25 years and taking into account performance degradation rates similar to those assumed for today’s silicon PV technologies, finding that module A could reach a levelized cost of electricity between $US$ 0.034 and 0.016 kWh, while module B could go as low as $0.030 and $0.014 kWh.

That these figures are already competitive with silicon PV production, comparing a theorized 100 MW production line with the several hundred gigawatts of silicon manufacturing and associated economies of scale already in operation, shows the potential for perovskites to achieve low manufacturing costs.

The group at IIT, however, notes that there are still several issues in perovskite production that will need to be ironed out for its techno-economic analysis to become a reality, and that changing material costs would also dramatically affect its modeling. “…economies of scale will help to bring the costs down,” they conclude. “The techno-economic framework helps researchers assess the feasibility of similar emerging technologies or this technology with the updated process, efficiency, stability and raw material prices in the future.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.