Among the many improvements being investigated for today’s energy storage technologies, replacing graphite with silicon stands out, given that silicon has the potential to hold ten times more energy than graphite.

Research into silicon anodes has made plenty of progress in recent years, with a few companies making moves toward commercialization and large scale production. However, there are still challenges and plenty more to be done at the research stage for silicon to realize its potential in energy storage.

The major challenge is that the material tends to swell up as lithium ions enter it. Eventually, this causes the anode to crack, flake, or otherwise fall apart, and it cannot regain its original structure. Plenty of solutions to this have been suggested – coating the anode, using porous silicon, and more have shown positive results.

So far, however, few researchers have delved deeply into the mechanisms at work within the anode as a battery cycle, and there are disagreements over exactly what is going on at the atomic level. “Many people have imagined what might be happening, but no one had actually demonstrated it before,” said Chongmin Wang, a scientist at Pacific Northwest National Laboratory (PNNL) in the United States.

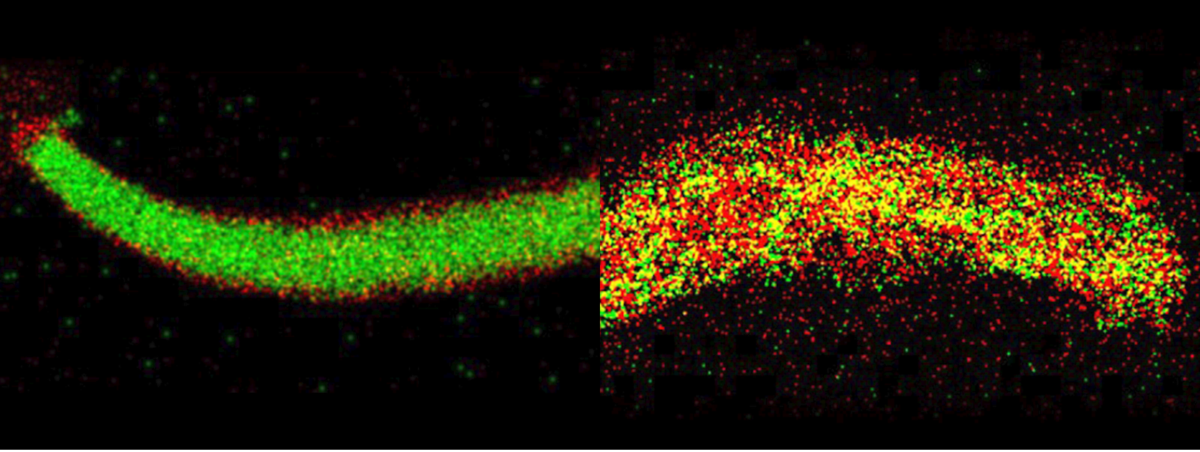

The group at PNNL set out to change this, combining two sophisticated imaging techniques – known as sensitive elemental tomography and cryogenic scanning transmission electron microscopy, with an advanced algorithm to observe the process in action, finding that the lithium anodes essentially push their way into the silicon structure, and then flow back out leaving large gaps in the structure. These gaps are then filled by the development of a solid-electrolyte interphase within the silicon (rather than at the edge of the anode where it should be), creating dead zones within the anode that quickly add up to significant capacity loss.

The group’s work on characterizing this mechanism is described in full in the paper Progressive growth of the solid-electrolyte interphase towards the Si anode interior cases capacity fading, published in nature nanotechnology. The group was able to observe the change in the anode structure after just one battery cycle. After 36 cycles the damage was said to be significant, and the anode was ‘destroyed’ after 100 cycles.

“This work offers a clear roadmap for developing silicon as the anode for a high-capacity battery,” said Wang. In the paper, the group concludes that its work demonstrates that the most effective way to improve on silicon anodes would be to focus on preventing or limiting the electrolyte from permeating the anode. The group further notes that, beyond silicon, its work could be applied to other high-capacity anode materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.