Signing off!

That's it for Intersolar Europe 2021! It was a smaller than normal event, yet happily, it felt more concentrated and focused than reduced. From new solar and storage products, to supply constraints, European manufacturing potential, and green hydrogen, the E Restart managed to pack a lot into a bustling few days.

The pv magazine live blog kept track of all the happenings along the way, but now it's time to hit the rails. Thanks Munich and see you all next year!

A mount-ain of experience

Today was Michael’s PV mounting system experience! After having visited the booths of K2, arausol, and PV Zimmermann Stahlbau, and before embarking on his train back to Berlin, he passed by Schletter.

One of the PV mounting system pioneers in Germany, it was back at this year’s Intersolar with a rather big booth in the first row in Hall A5, where it introduced a new flat roof PV system.

Stefan Gelhaar from the sales department explained the product it is more flexible than its predecessor, while the clamps can be fixed at any tilt, allowing the system to be used for different tilt angles. The height of the supports may also be easily adjusted by adding additional pieces.

Overall, the system is very modular to reduce the number of different pieces in the supports.

Mounting system sensors

The good vibes are continuing into day three of Intersolar Europe, as can be witnessed here when Michael Fuhs met Robert Zimmermann, CEO of Zimmermann PV Stahlbau (pictured right). The company is a big PV mounting systems player developing fixed-tilt, tracker, and floating systems for utility-scale solar projects.

This year, Zimmermann says the company will probably ship 1.1 GW worth of mounting systems, comprising 50,000 tons of steel. The PV Zimmermann Stahlbau floating system (also pictured) has been used in Baywa r.e.’s Netherland’s floating PV projects, for example, where around 200 MW have been installed.

Now Zimmermann has installed sensors in its mounting systems to see where they can be optimized and how to reduce the material used. It is also embracing innovations on the PV tracker level, with the company now boasting a tracker system that allows one to install modules vertically – perfect for agriPV projects!

One-stop-shop Kopp

Yesterday, Blake Maitch visited Swedish battery storage manufacturer Nilar to find out about its new nickel metal hydride battery (which, by the way, won the pv magazine energy storage highlights award in 2020!)

Michael Fuhs (pictured left) has now met with CEO Stephan Dörrschuck of Kopp (pictured right), a distributor for Nilar. A one-stop-shop of sorts, one can buy the storage system together with Kostal’s hybrid PV inverter, for example.

The company is also producing its own hardware and software, in addition to developing PV inverters and energy management systems.

Kopp’s strategy is to not only distribute products but also to see where it can add value. This is, according to Dörrschuck, wherever it is possible to control something.

Sax Power’s ess award for innovative battery

Sax Power was presented one of the three ess awards handed out by the event organizer, which together with Intersolar and two other shows, is called the “The smarter E”.

Technologically, Sax Power’s storage product is highly innovative. The battery, which managing director Lei Shen holds in her hands, integrates power electronics and battery cells. A complicated design of switches, and controlled by a computer, it is used to directly create AC output. Shen told pv magazine’s Michael Fuhs that the challenge was to find less expensive designs – a task with which Sax Power has been successful, she said.

What’s more, according to Shen, this switching technology – based on railway technology – has several advantages compared to conventional lithium-ion battery storage system designs: Her setup allows the aging characteristics of the battery cells to be better controlled, which may result in longer lifetimes. Furthermore, when idle, the battery does not use voltage, which could be a safety advantage.

Shen aims to start using the technology for home storage systems (see the stylish box in the background). In the future, her vision is that it will also be used for electric vehicles. Indeed, she believes it could be used as a solution by German automotive companies, which face the competition of Tesla’s advanced technology. In the past year, Shen has found investors, which have enabled her to build up a small manufacturing base in South Germany.

Our German-language readers can read about the startup in the latest edition of pv magazine Germany.

What’s behind the booths?

Much has been made of the good foot traffic, busy booths, and unexpectedly large crowds in Munich over the past three days. But if you look a little closer, behind the booths in some of the halls, one of the reasons for the compression of activity becomes clear.

Hall A5 is a good example: The hall hosted many of the solar manufacturing technology providers, and the place was buzzing. But behind the petitioning lay a cavernous expanse comprised of a whole lotta nothing.

To steal some confectionary marketing: maybe it is the sections of nothing that make it really something.

How many screws do you need to mount a utility-scale solar plant?

Michael Fuhs passed by arausol Solartechnik to discover the answer. He met with Henning Wicht (pictured right), who is well known to pv magazine readers in his former capacity as one of the leading solar analysts, previously working for IHS.

He has now joined Arausol as Director of Photovoltaics. The company develops mounting systems and works as an EPC and PV project developer.

CEO Jaime Arau (pictured left) is proud to proclaim that one needs just four screws to build one section of the mounting system table. In his hands, he is showing us a clamp the company has also designed for easy use.

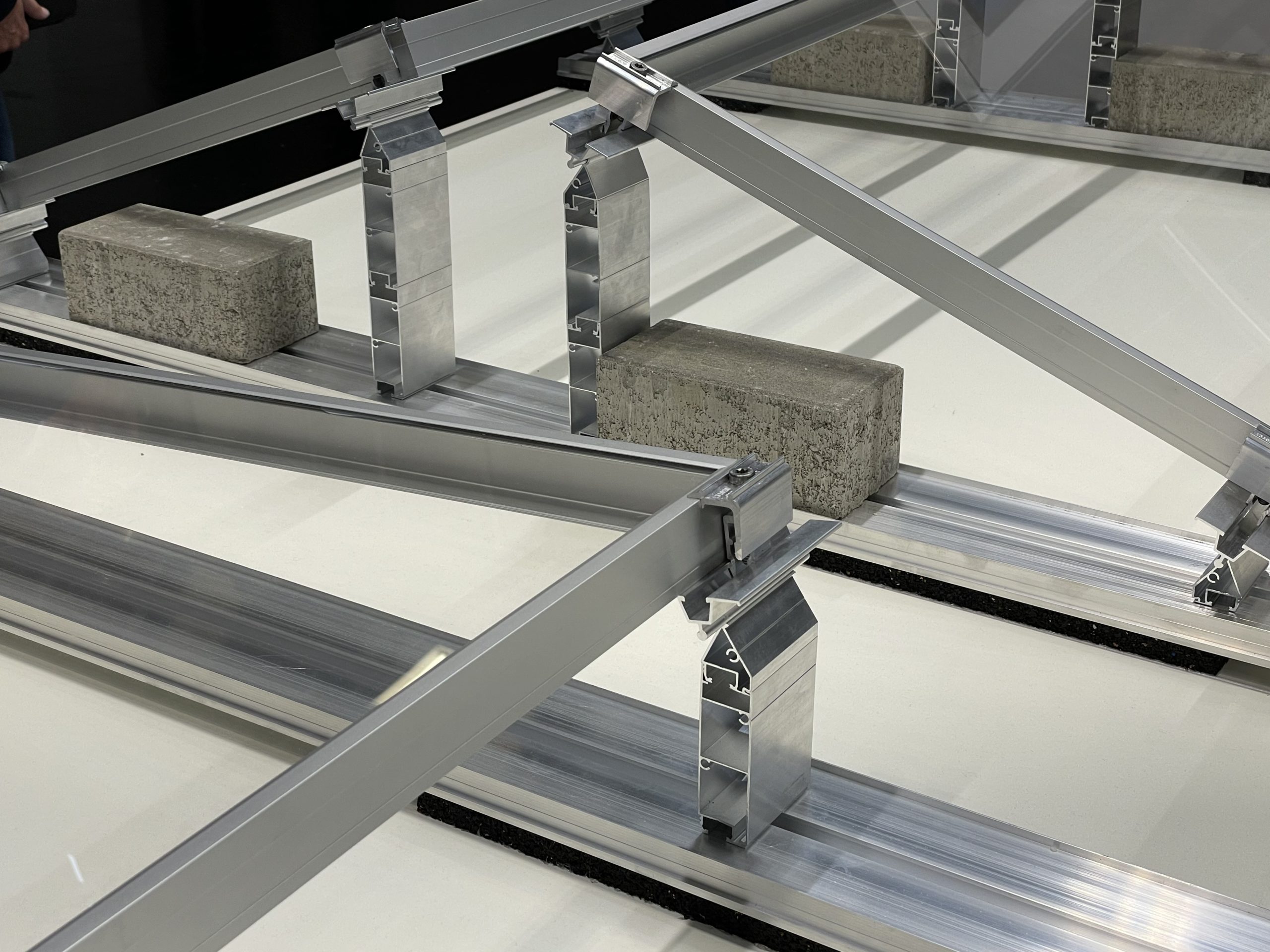

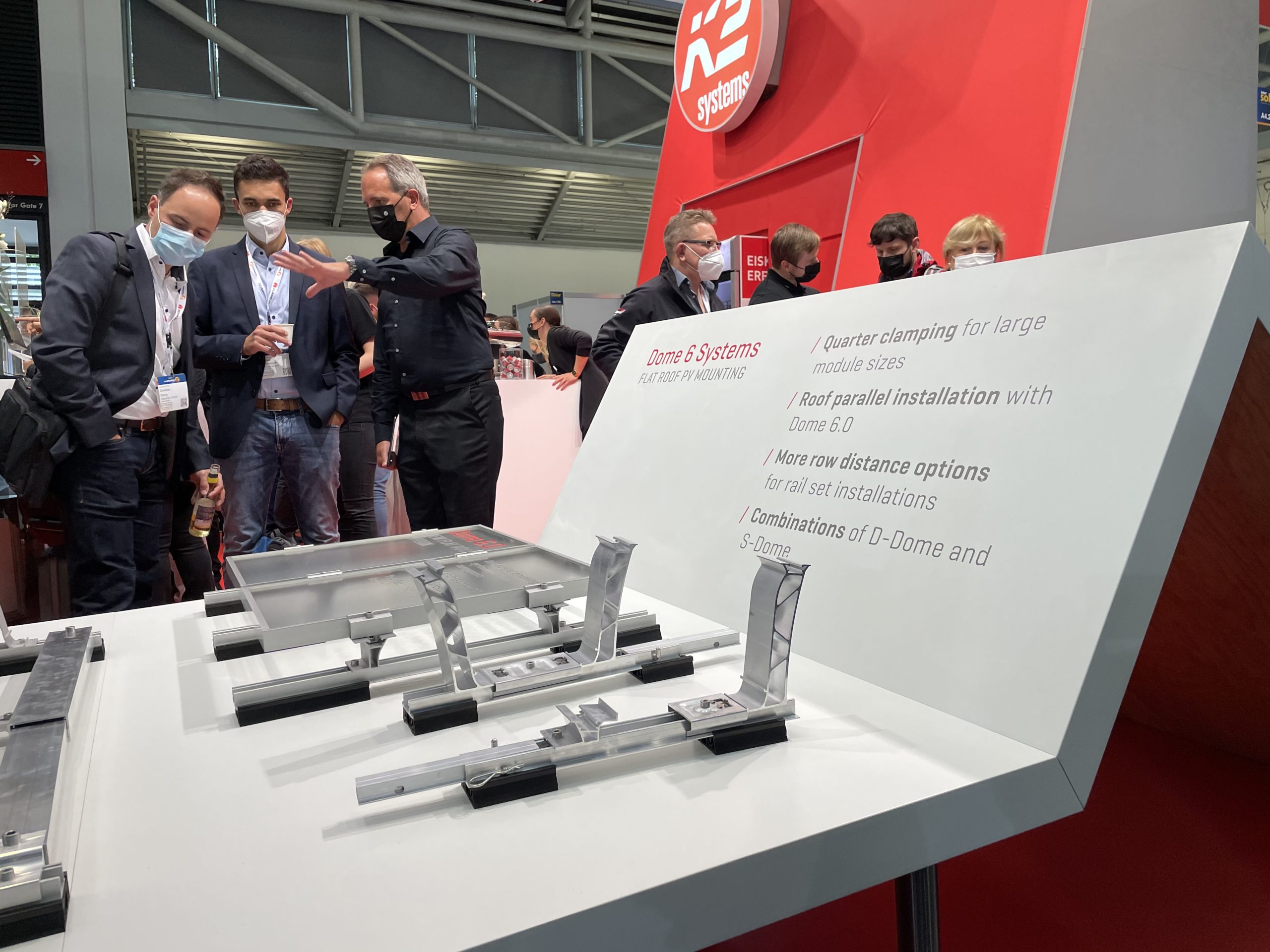

K2’s contribution to installation efficiency

We already reported on K2’s new offer for the Mena region yesterday; however, the company is also addressing German and European solar installers with novelties. Already one year old – but due to Corona the first time at Intersolar – is K2’s pre-mounted version of its Dome 6 system for flat roofs.

Highlighting its time saving properties, Stephan Klopfer, Area Sales Manager, tells pv magazine’s Michael Fuhs, that the pre-mounted system can help shave 50% off the time it takes to install a regular mounting system, e.g., rather than the around one hour it takes to install a normal mounting structure of a 10 kW system, for example, the new K2 product reduces this time by 30 minutes.

To adapt to the fast-changing PV module sizes, the company has enlarged the length of the rail and changed the design of the clamps. And they can also be used to clamp at other positions on the module, which some manufacturers require for their larger formats. The system is now usable for module sizes up to 1.17 by 2.34 meters.

Also helping to reduce installation times, K2 is continuing interfaces of its statistical software planning tool with those of inverter manufacturers. When installers have carried out their statical designs, they can now directly import the design data to the planning tools of Fronius, Goodwe, Kostal, SMA, and Solaredge, which are then used to plan the electrical design.

Spotted at the pv mag booth!

[TRADESHOW

]

Spotted on our @Intersolar booth: @ChristianPhoDuc, MD of #hydrogen projects at @Smartenergy17!

Come by and chat with us on booth A6.450 – we have loads of fun as you can tell

For more fresh news

https://t.co/0NOrfOdbRS#pvmagazine #intersolar21 pic.twitter.com/XR2RxuTlef

— pv magazine (@pvmagazine) October 8, 2021

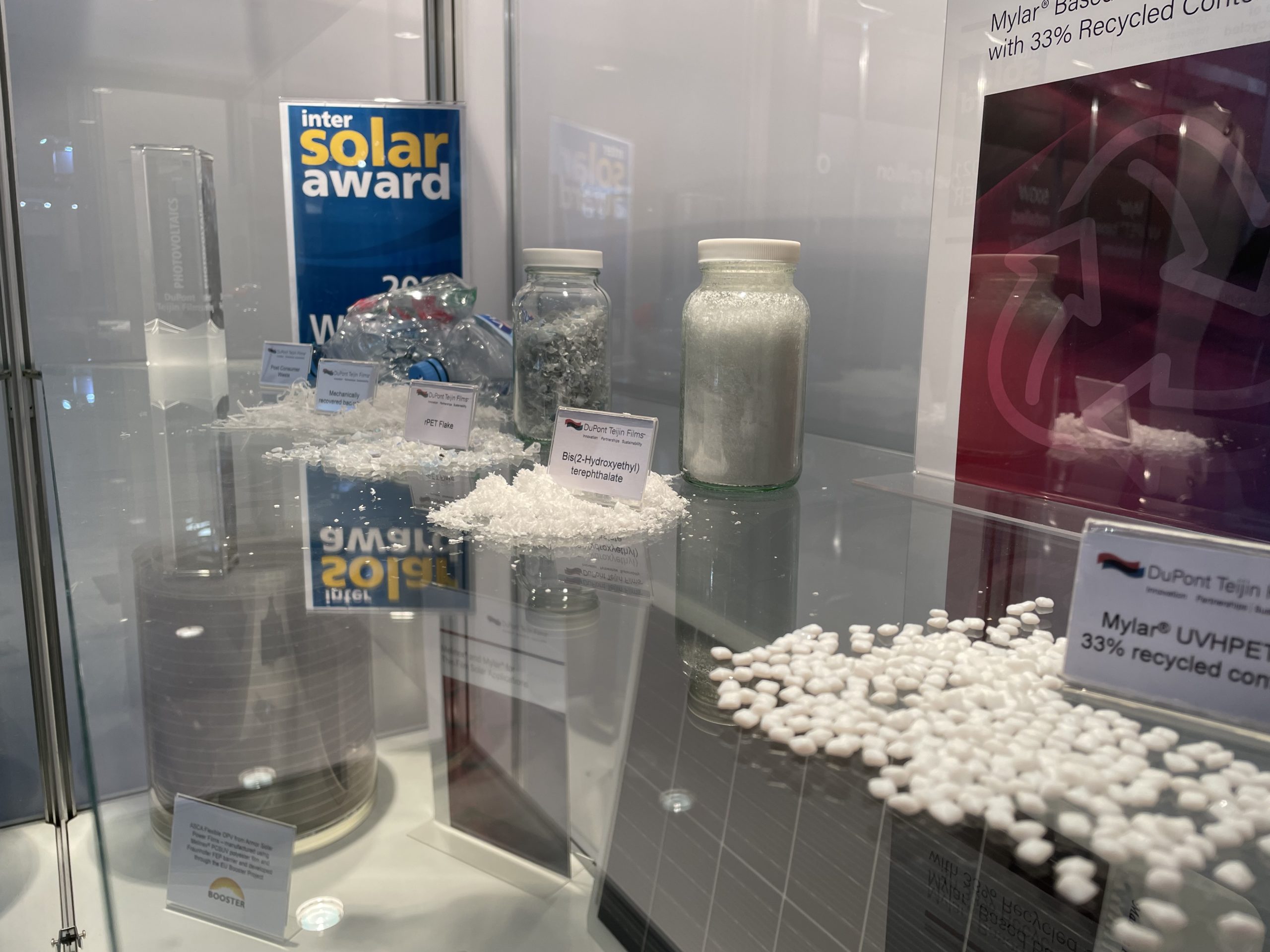

Desperately seeking old PET backsheets

Two PET backsheet innovators are on the search for end-of-life backsheets to help them close the loop on the material that can be key to PV module durability. Coveme and DuPont Teijin Films have been collaborating on a PET recycling project.

The first stages of the project involved recycling PET plastic bottles into the raw material, which could then be fashioned into new backsheets. DuPont Teijin has pulled off the trick of turning old bottles into precursor PET backsheet material, and it picked up a 2021 Intersolar Award in the process.

Italy’s Coveme stepped in next and has produced backsheets that it says do the trick needed for PV module making. It’s upcycling, but it’s not quite closing the loop when it comes to PV. The two teams are looking for end-of-life modules that can be tested and then the PET backsheet isolated, so that DuPont Teijin and Coveme can then repeat the trick they’ve pulled off with old water bottles.

“We could call it [the project] back-to-back” suggested Steve Davies, from DuPont Teijin. “But It’s actually back-to-backsheet,” added Coveme’s Michele Vannini.

Whatever the name, if you’ve got old modules made of PET backsheets, and can partner on the project, get in touch with Coveme to make circular solar manufacturing a reality.

Sens-ational monitoring solutions

For many years, companies have been coming up with new monitoring and alarm management platforms. Brand new at this year’s Intersolar Europe, Sens presented its Sensaia solution, as pv magazine’s Michael Fuhs discovered.

The team around Head of Energy Moritz Wickert (left) developed the device using the AI competence of Sens’ parent company Steag – a big player operating in Germany’s coal and gas power plant sectors, among others. Sens, which also builds solar plants globally, is the renewable arm of Steag.

Discontent with existing monitoring solutions, the team developed a new one using the AI data gathered from their existing solar plants. Sensaia now incorporates a “holistic validation” of the many data from them. As a result, all alarms now immediately go through an AI-based quality check based on historical data to eliminate false alarms.

The experts are confident that, among other benefits, the platform correctly predicts the financial losses which arise due to faults or soiling of PV modules. This allows O&M service providers to know when to act. The solution is also sold as a service to other asset managers.

Sensaia is targeted at operators of PV plants above 1 MW in size.

Avoiding module failure

In traditional energy storage solutions, multiple PV modules are connected in a series to a rack, and multiple racks are connected in parallel. Thousands or even tens of thousands of modules are coupled with each other. Thus, if one module fails, the others will be affected.

Blog sponsor Huawei says its solution helps customers avoid this issue and reduce the LCOS by up to 20%. How does it do it? The solution supports battery pack-level and rack-level optimization. Through this, the solution can achieve more refined management, with an accuracy of no more than a dozen batteries. If you’re interested in finding out more, visit B5.510!

Sign The Green Hydrogen Manifesto today!

As part of the Smarter E Europe Restart 2021, Hydrogen Europe, the German Hydrogen and Fuel-Cell Association DMV, the European Electrolyzer & Fuel Cell Forum EFCF, and Smarter E Europe have combined “to send a clear signal in favor of decarbonization and a sustainable circular economy” through “The Green Hydrogen Manifesto”, writes editor Blake Maitch.

“Against the backdrop of the current realignment in politics, our manifesto aims to encourage decision-makers to factor in green hydrogen – whether in the energy sector or the economics sector,” says Werner Diwald, Chair of the German Hydrogen and Fuel-Cell Association DWV. “Because hydrogen that is produced from renewable sources is not only important for the energy transition. More importantly, it also provides huge opportunities for the economy of the European Union.”

The Manifesto presents 12 action points to the EU, as well as regional policymakers and governments. Actions include:

- The C02 content of energy carriers should serve as the new currency for energy systems;

- Certification of hydrogen as a global commodity; and

- Appointment of a dedicated EU Hydrogen Special Envoy.

Well over 50 companies and organizations are already signatories and supporters can still sign the manifesto at ees Europe Restart 2021 until 3:30 pm October 8, or online here.

Mondragon makes high-tech, adapting equipment its mantra

There’s been a genuinely ebullient mood among production equipment suppliers throughout the three days of Intersolar Europe, with a range of new EU-based PV cell and module projects presenting a wealth of opportunities for production equipment suppliers, according to editor in chief, Jonathan Gifford.

Basque-based production equipment supplier Mondragon Assembly had its new solar head Iñaki Madina on site, and he reported that the company had been swamped with enquiries over the first two days. There had not been even time for lunch, Madina reported – a doubled edged sword, it seems.

Iñaki Madina had taken over from Mondragon’s former solar business head Iñaki Legarda a little less than a year ago, and it was certainly not a case of the lesser of two Iñakis. Madina set out his vision and strategy for supplying the European solar market over the next few years, and it’s comprised of some exciting stuff.

On one side, he sees the future of European manufacturing as being high-tech projects, with a HJT, ECA encapsulant project and an IBC project two recent examples of Mondragon technology projects on display at the booth.

The other component of Mondragon’s strategy is the supply of relatively novel manufacturing concepts, such as automated BIPV module production, and production tools for specialized floating PV and agri-PV projects.

“Our basis to invest in technology with partnerships, in these new technologies, and what we are good at making equipment in which we adapt the new technology,” said Madina. “Our strategy is also focused in niche applications and adapting the solution for the customer.”

The hidden champions

Despite being hidden at Fraunhofer ISE institute’s booth, pv magazine’s Cornelia Lichner managed to unearth M10 Industries Business Development Manager, Michael Kroeffges and even CEO Philipp Zahn.

The two can sell you the stringers for their newest shingling matrix technology, which the company developed in close cooperation with Fraunhofer ISE. These devices can interconnect 12,000 cells per hour, which is probably comparable to conventional soldered connections.

The special thing about the shingling matrix is that soiling or a shadow on one point of the module does not affect an entire cell string. Instead, the current can flow around the obstacles. In addition, the shingled modules are aesthetic, with no gaps disturb the picture.

The finished module doesn't have to be square or flat, says Kroeffges. A gently curved car roof is exhibited as proof, which unfortunately reflects too much light for photos, but round or oval modules and even bifacials are also easy to produce, as the manufacturer is not bound by usual cell sizes.

Fringe copper coverage

One of the more unusual booths at Intersolar is from copper merchant Gindre, writes pv magazine’s Tristan Rayner. Despite being in the market for close to 200 years, it's Gindre's first time exhibiting at Intersolar.

On offer? Sustainable copper, 100% recycled. Who's interested? Battery companies, with Yves Lembke, Product Manager for E-Mobility, saying he was surprised by the number of battery startups interested in copper for upcoming projects.

Lembke confided to pv magazine it's a game of patience, with initial conversations taking up to a year to develop into orders. And, with demand increasing, Gindre is seeing improving margins after Covid-19 related slowdowns.

Live coverage from Days 1 & 2

Over the past two days, the pv magazine team has scoured the halls of Intersolar, meeting with the established market leaders, the new kids on the block, and the industry’s analysts to bring you the latest PV and energy storage trends from the ground.

We've covered everything from agrivoltaic wine, solar fencing, and giant dogs, to fears about supply shortages and innovative new products.

Make sure you check out the live coverage from Day 1 and Day 2. And stay tuned for more news from the final day of the show!