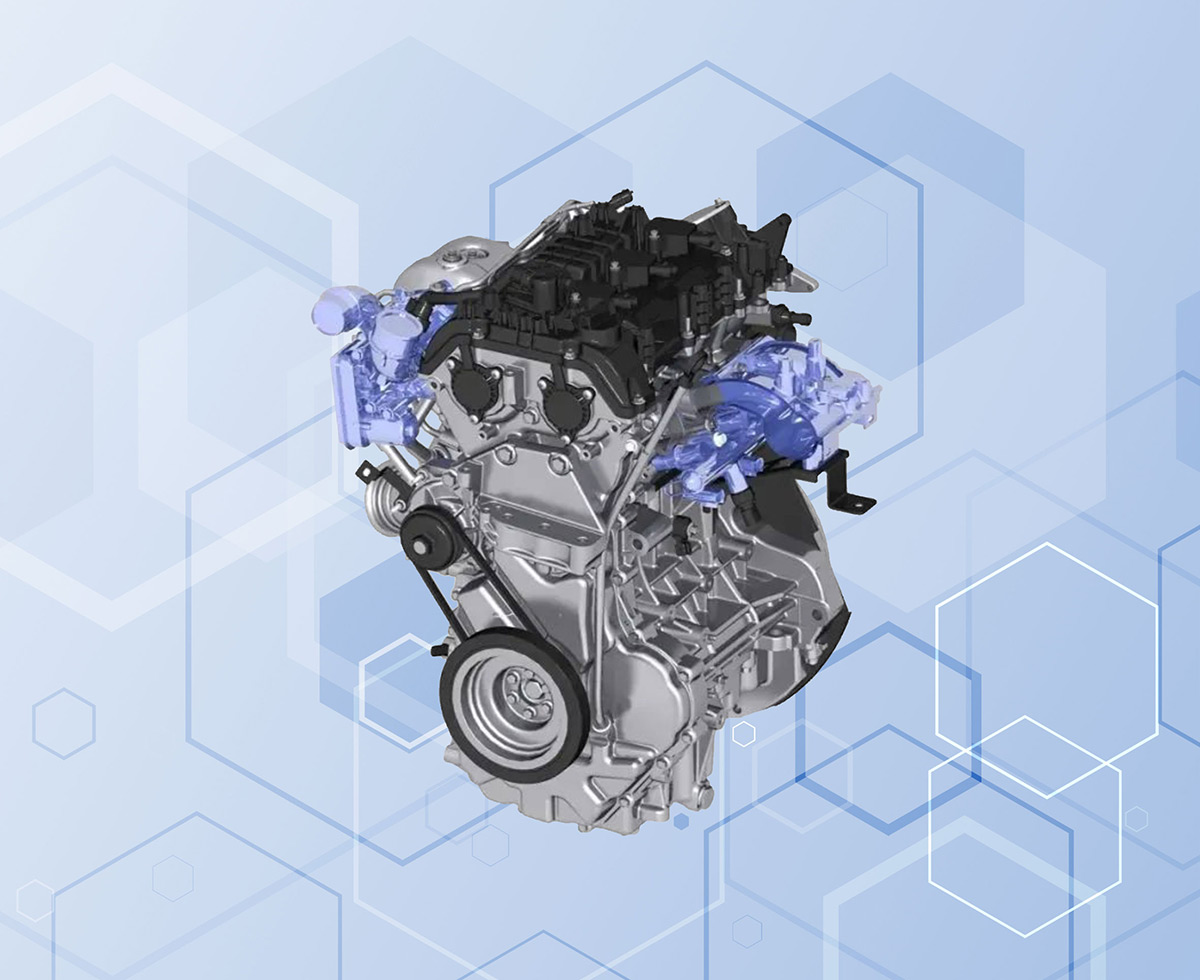

Chinese auto company GAC Group has announced a “technology leap” and entry “into the zero-carbon emission era,” as it ignited its first independently developed hydrogen engine. “Using core hydrogen engine technology as a foundation, GAC R&D centers optimized the technology with a number of innovations,” the company wrote last week. “These include the newly developed combustion chamber, which improves the mixing process of hydrogen and air, and improvements to the hydrogen supply system, which improves power density and reduces the risk of hydrogen leakage.” GAC said its R&D staff would continue to “carry out thermodynamic calibration and mechanical development of the hydrogen engine, with the eventual aim of loading the entire … vehicle.” The Guangdong-based company is also looking for collaborators for hydrogen production, storage, and hydrogenation.

The International Energy Agency (IEA) has said investment over the next decade will be critical in determining long-term hydrogen objectives. “Every year until 2030, investments of $7 billion in electrolyzers will be required (30 times recent record investments), and $4 billion in FCEV [fuel-cell electric vehicle] deployment will be needed (14 times record investments),” the IEA wrote in its Global Hydrogen Review 2021, published last week. “To achieve net zero emissions by 2050, global cumulative investments must increase to $1.2 trillion by 2030 and $10 trillion by 2050.” In the executive summary of the report, the IEA said global electrolyzer capacity, which doubled in the last five years to reach just over 300 MW by mid-2021, needs to accelerate. “Around 350 projects currently under development could bring global capacity up to 54 GW by 2030,” added the report. “Another 40 projects, accounting for more than 35 GW of capacity, are in early stages of development. If all those projects are realized, global hydrogen supply from electrolysers could reach more than 8 Mt by 2030. While significant, this is still well below the 80 Mt required by that year in the pathway to net zero CO2 emissions by 2050 set out in the IEA Roadmap for the Global Energy Sector.” The IEA wrote, Europe is leading electrolyzer capacity deployment, with 40% of global installed volume, and is set to remain the largest market in the near term, while Australia, Latin America, the Middle East, the U.S., and China could catch up in the long term. On the other hand, Canada and United States are the leaders in the carbon capture, storage and use technology needed for blue, natural gas-fired hydrogen production.

Swedish bearing and seal manufacturer SKF is teaming up with Luleå University of Technology to develop fossil-free steel for bearings. SKF will fund research on hydrogen use in industrial processes from the university’s CH2ESS initiative. It will also take part in research to speed up the development of fossil-free bearing steel. “Mechanical components are very important to ensure … function and operation in future hydrogen systems,” Victoria Van Camp, president of SKF Technology said in a press release today. Research areas will include hybrid ceramic bearings, and electric vehicles. The two partners will also develop and commercialize fossil-free bearing steel production. “SKF’s expertise in fluid machinery, material science, production technology and IoT [internet-of-things] solutions will actively contribute to the work,” added the press release.

London-based green H2 business Octopus Hydrogen, U.K.-focused, U.S. private equity-backed solar developer Innova Renewables, and Gloucestershire-headquartered renewables consultant Novus have formed a strategic partnership to build green hydrogen production facilities alongside their 4 GW of U.K. solar, wind, and battery projects. Octopus Hydrogen, part of London-based asset management business Octopus Energy Group, will design, build and operate hydrogen production plants at several of Innova’s renewables sites, said the companies, adding that electrolyzers will typically be between 2 and 20 MW in scale. “The green hydrogen production facilities will be directly connected to on-site renewable energy [generation] which will be purchased via long term power purchase agreements, producing between 500 and 2,500 kg of hydrogen per day,” read an announcement today.

In preparation for the COP26 climate change summit in Glasgow next month, the British government has announced measures to support climate action and energy transformation. Last week, it awarded funding to 15 projects to help U.K. airports handle new types of electric and hydrogen aircraft. “In the future, we believe there will be a hydrogen-electric engine in every aircraft as this is the only viable way to deliver truly zero-emission aircraft and to comprehensively tackle the industry’s growing climate impact,” said Val Miftakhov, chief executive of the U.S.-based ZeroAvia company which is designing such aircraft. “When we deliver our first hydrogen-electric powertrains into service, in 2024, operators need to be able to fuel their aircraft with low-carbon hydrogen, and today’s announcement is a big step towards that.” U.K. prime minister Boris Johnson is expected to announce at the Conservative Party conference that all of Britain’s electricity will come from renewables by 2035.

The European Bank for Reconstruction and Development (EBRD) and the Moroccan Research Institute for Solar Energy and New Energies have signed a memorandum of understanding to collaborate on renewables, green hydrogen, and new technology. “The EBRD is fully committed to supporting the development of green hydrogen value chains,” said Harry Boyd-Carpenter, EBRD managing director for the green economy and climate change, last week. “In combination with competitive renewable electricity, green hydrogen is a key ingredient in accelerating the decarbonization of hard-to-abate sectors and has strong potential in Morocco. We are very pleased to start our cooperation with [the Moroccan Research Institute for Solar Energy and New Energies].”

Lifte H2, a company focused on hydrogen supply chains, is expanding its presence in Berlin and Boston while launching a ‘technology-differentiated hydrogen infrastructure development service.' “In an industry where hydrogen-specific product and project experience is hard to come by, Lifte provides a unique combination of relationships, experience, technology, and capabilities,” said CEO and co-founder Matthew Blieske in a press release yesterday. The company expects to double the size of its workforce by early next year, to meet demand.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.