Scientists from Nanyang Technological University, Singapore (NTU Singapore), have developed a novel technology that they claim is able to prevent internal short-circuits in lithium-ion batteries.

These short-circuits still represent a major hurdle to overcome for battery makers, as lithium-ion devices can catch fire if they are damaged or not properly manufactured. What causes these short-circuits, the research team explained, is the formation of dendrites, which are needle-like projections that can grow inside a battery and cause a number of undesirable effects, including, in a worst-case scenario, complete battery failure and even fires. The dendrites cross the separator between the positive cathode and negative anode electrodes of a lithium-ion battery during charging.

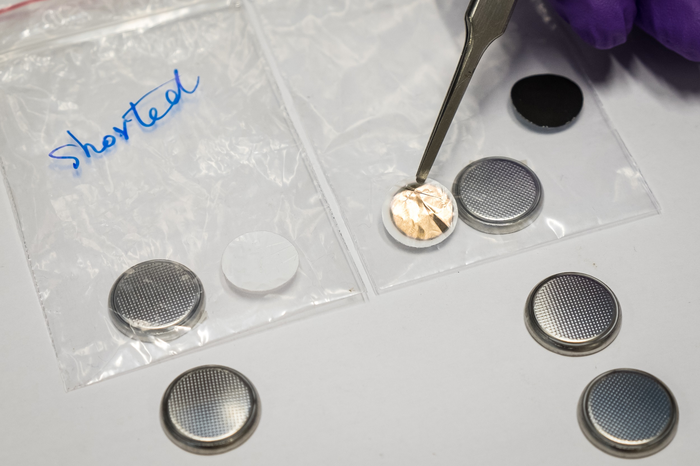

In order to prevent the dendrites from reaching the cathode, the academics placed what they called an “anti-short layer” on the separator itself. “Instead of preventing the formation of dendrites, we decided to make use of their intrinsic properties by coating an additional layer of conductive material on the separator for these dendrites to connect with,” said NTU researcher Jason Xu. “Once the dendrites make the connection, [they] will not be able to continue their growth further, thus preventing them from ever reaching the other side.”

The additional layer works as an interface on behalf of the negative electrode to exchange lithium-ions with the positive electrode. It was tested on more than 50 cells with different li-ion battery architectures and, according to the scientists, no short-circuits arose during the charging phase, even with the battery cells that exceeded their expected lifecycle. “The anti-short layer is a common material used in battery manufacturing and can be easily integrated into the current separator manufacturing process, making it easy for companies to adopt and scale up,” the Singaporean group stated, noting that it would increase lithium battery production costs by around 5%.

NTU University's spin-off NTUitive is planning to bring this novel technology to commercial production and is currently in the process of securing a patent.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

7 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.