Solar thermophotovoltaics (STPV) is a power generation technology that utilizes thermal radiation to generate electricity in a photovoltaic cell. An STPV system consists of a thermal emitter that can reach high temperatures, near or beyond 1,000 degrees Celsius, and a photovoltaic diode cell that is able to absorb the photons coming from this heat source. This technology has raised a strong interest among scientists in the past decades, as it is able to capture sunlight in the entire solar spectrum and has the technical potential to beat the Shockley-Queisser limit of traditional photovoltaics. The efficiencies reported so far, however, are still too low to make it commercially mature, as STPV devices still suffer from a series of optical and thermal losses.

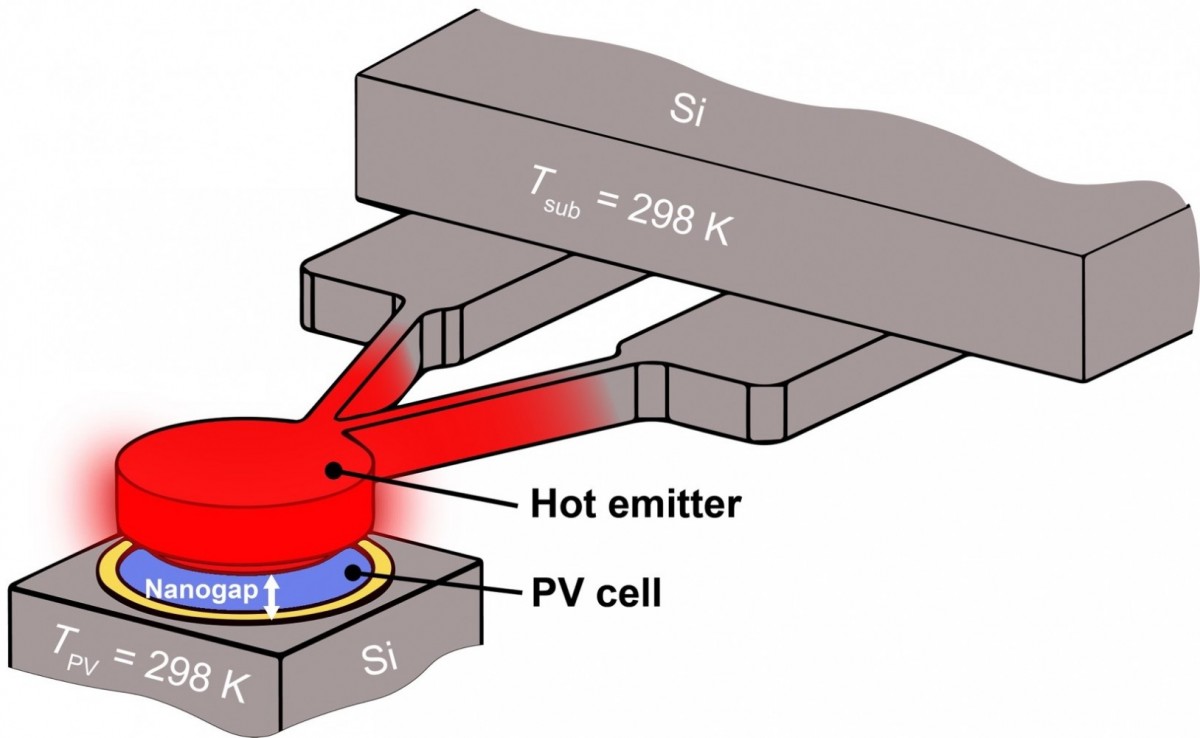

With this in mind, a group of researchers from the University of Michigan and the U.S. Army Research Laboratory has proposed a new approach for STPV consisting of reducing the separation between the emitter and the photovoltaic cell to a nanoscale. The researchers call their approach ‘near-field thermophotovoltaics' and claim it is able to achieve high power density and high power conversion efficiencies.

The scientists created an STPV device with an emitter that can reach temperatures as high as 1,270 Kelvin, and a thin-film photovoltaic cell based on indium gallium arsenide (InGaAs) which is said to be capable of absorbing above-band-gap (ABG) thermal radiation while minimizing absorption of sub-band-gap (SBG) photons. “The photons above the band-gap of the cell are efficiently absorbed in the micron-thick semiconductor while those below the band-gap are reflected back to the silicon emitter and recycled,” explained Stephen Forrest, professor of electrical and computer engineering at the University of Michigan.

The solar cell was grown on thick semiconductor substrates and the thin semiconductor, active region of the cell was then peeled off and transferred to a silicon substrate. A nanopositioning platform in a high-vacuum environment was used to parallelize, and gauge the distance between, the emitter and the PV cell. The emitter and PV cell were initially separated by only 7µm and the cell was then placed closer to the emitter using a feedback-controlled piezoelectric actuator, which is a tool able to convert an electrical signal into a controlled physical displacement.

According to the researchers, the STPV device exhibited record power densities of around 5 kW/m2 at an efficiency of 6.8%, which they stated is an order of magnitude larger than systems previously reported in the literature. The reported efficiency defines the ratio of electricity output of the PV cell to the radiative heat transfer from the emitter.

“This current demonstration meets theoretical predictions of radiative heat transfer at the nanoscale, and directly shows the potential for developing future near-field TPV devices for army applications in power and energy, communication and sensors,” said researcher Pani Varanasi.

The novel approach is described in the paper Near-field thermophotovoltaics for efficient heat to electricity conversion at high power density, published in nature communications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

12 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.