For scientists working on improving today’s energy storage technologies, energy density is among the key factors – increasing this could allow for batteries that store more in energy in less space, and run for longer in between charges.

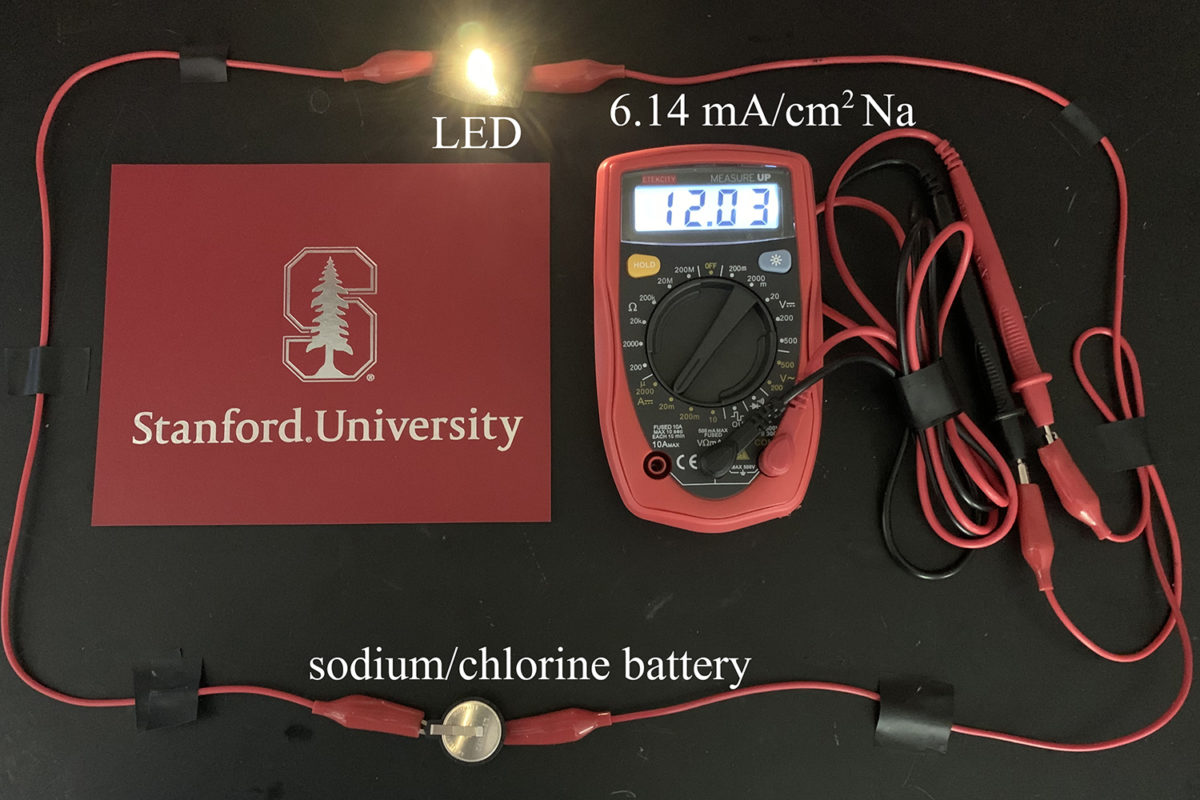

A group of scientists led by Stanford University has demonstrated a new battery chemistry that reached 1,200 milliamp-hours per gram of positive electrode material – around six times higher than today’s commercially available lithium-ion batteries. With further work to scale up the batteries and improve on cycle life, the group is convinced that the new sodium or lithium chloride batteries could be used to power sensors and satellites, and in other situations where regular charging is not practical.

The group was actually working on thionyl-chloride, commonly used for single-use batteries, when it first made the discovery of a reversible reaction involving chlorine and sodium chloride. They have since spent several years experimenting with different materials to improve the efficiency of this reaction, and have now seen encouraging results thanks to an electrode made of a porous carbon material, developed at the National Chung Cheng University of Taiwan.

The battery is described in the paper Rechargeable Na/Cl2 and Li/Cl2 batteries, published in Nature. The group worked with an aluminum chloride electrolyte with fluoride additives, and either sodium or lithium as the negative electrode. The battery works via redox reactions at either side. “The chlorine molecule is being trapped and protected in the tiny pores of the carbon nanospheres when the battery is charged,” explained Stanford scientist Guanzhou Zhu. “Then, when the battery needs to be drained or discharged, we can discharge the battery and convert chlorine to make NaCl – table salt – and repeat this process over many cycles. We can cycle up to 200 times currently and there’s still room for improvement.”

The group says that the prototype developed for the paper might already be suitable for use in small devices such as hearing aids, and that they envision the battery one day being used to power sensors or satellites – applications where frequent recharging is impossible or impractical.

They acknowledge, however, that turning the promising discovery of a reversible reaction for chemical energy storage into an actual practical battery will be a lengthy and challenging process. “For consumer electronics or electrical vehicles, much more work remains to engineer the battery structure, increase the energy density, scale up the batteries and increase the number of cycles,” they conclude.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.