A group of scientists from the University of North Carolina has developed a mini perovskite solar module with a power conversion efficiency of up to 19.3% efficiency by applying a novel approach for interface engineering.

“These panels are designed for general purpose, which means all applications for which a regular PV panel would be applied,” UNC researcher Jinsong Huang told pv magazine.

The device was built with a new technique aimed at stabilizing the embedded perovskite-substrate interfaces in the solar cells used. The common approaches, the researchers explained, had previously focused on stabilizing perovskite-metal electrode interfaces through surface passivation or post-fabrication treatment. “Degradation of perovskite solar cells starts from the interfaces, including both perovskite-metal

electrodes and perovskites-substrates, where defects enrich,” they stated in the paper Stabilizing perovskite-substrate interfaces for high-performance perovskite modules, published in Science. “Stabilizing the embedded bottom interfaces is as important as that of [the] top interface.”

The U.S. group discovered that a high density of voids is concentrated around these interfaces and that the perovskite around these voids is subject to faster degradation. Their formation is attributed to the presence of dimethyl sulfoxide (DMSO), which is a non-volatile solvent that is commonly used to improve perovskite film morphology near the bottom of perovskite films.

The solvent was replaced with a solid-state, lead-coordinating additive of carbohydrazide (CBH), which the scientists claim was able to reduce the formation of the voids and, at the same time, to act as an effective reductant agent for the detrimental iodine formed in the perovskite material. “CBH barely evaporated during thermal annealing and thus remained within the perovskite films,” the academics explained.

According to them, the new additive enabled the fabrication of perovskite solar cells with a stabilized efficiency of 23.6%, an open-circuit voltage of 1.17 V, a short-circuit current density of 24.1 mA/cm-2, and a fill factor of 0.842. The perovskite films used for the cells were prepared with a room-temperature blade-coating method.

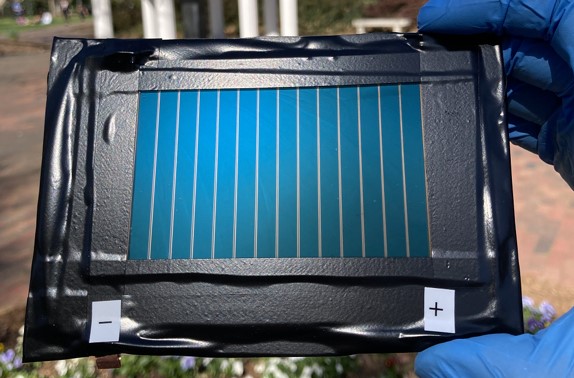

These cells were then used by the scientists to produce mini modules with efficiencies of 19.3 and 19.2%, with aperture areas of 18.1 and 50cm2, respectively. These results were certified by the U.S. Department of Energy's National Renewable Energy Laboratory (NREL), which tested 112 mini panels sent by the UNC research team. More than half of the devices exhibited efficiencies of over 19% and around 77% of them over 18.5%. “Furthermore, the long-term operational stability of the highly efficient perovskite mini-modules was also tested with the statistical results,” they further explained. “Five mini modules retained 85% of initial power conversion efficiencies after 1,000 hours of light-soaking under simulated 1-sun illumination at 50 degrees Celsius.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.