A recent study conducted by scientists from Germany’s Jülich Institute for Energy and Climate Research (IEK-5) proposes the integration of battery storage into systems for hydrogen production relying on PV-powered water splitting electrochemical (EC) cells.

According to the researchers, directly integrating batteries in these systems without adding power management electronics would help smoothen PV power fluctuation and, simultaneously, stabilize the performance of the EC components. “This combination can be considered as a basic unit of a PV-driven power source with both short-term and long-term energy storage functions,” they stated.

In the proposed system configuration, the PV cell is connected in parallel to the EC unit and the battery. The latter can shift working point towards lower working point voltage, which the German group describes as having high relevance for solar-to-hydrogen efficiency. “We can see that battery can improve coupling in otherwise mismatched PV-EC system, which is a particular case of matching PV to a load with aid of a battery,” it explained.

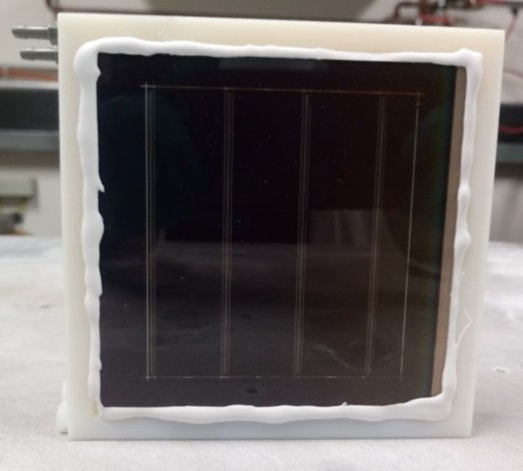

The device's PV unit was built with a triple‐junction silicon solar cell with a power conversion efficiency of 11.3%, an open-circuit voltage of 2.25 V, a short-circuit current of 7.4 mA/cm2,, and a fill factor of 67.9%. The electrochemical cell was made of polyether ether ketone (PPEK) filled with a potassium hydroxide solution and nickel catalyst pair. The lithium-ion battery was built with a commercial lithium ferrophosphate (LFP) cathode, a lithium titanate (LTO) anode, and a separator based on a glass fiber membrane soaked with commercial electrolyte LP30. Each of the three components is of small scale with areas of 1 cm2 and below.

The scientists explained that when sunlight hits the solar cell during the daytime, the PV unit provides a voltage of approximately 2.0 V across the EC cell and the battery while supplying a current of 3.8 mA flow through the EC and 0.6 mA through the battery. When the full state of charge is reached, the battery current is about zero for almost 40 minutes and the EC cell receives all the current from the PV cell. “Once the light is turned off and solar cell is disconnected the discharge phase begins,” they further explained.

The performance of the system was compared with that of an identical device operating without the battery and the scientists found that their novel configuration can not only smoothen out the PV power fluctuations and facilitate power coupling, but also improve solar to hydrogen efficiency.

“Simple parallel connection of PV, EC, and battery in PV-EC-B system is sufficient to provide partial storage of the PV energy and its further utilization for water splitting when PV is idle at night times,” the scientists stated, noting that the battery open-circuit voltage is a key parameter to maximize solar-to-hydrogen efficiency under a given duty cycle. “High battery capacities and duty cycles with short light periods followed by long dark periods are beneficial for solar-to-hydrogen efficiency in PV-EC-B system allowing utilization of battery charge at lower current and hence lower overpotential in the EC cell.”

All the details on the system configuration can be found in the paper “Storage batteries in photovoltaic–electrochemical device for solar hydrogen production,” published in the Journal of Power Sources.

The same research group unveiled in June 2020 an integrated PV-EC device with an active area of 0.5 cm2 developed with solar panels based on triple‐junction thin‐film silicon solar cells with an efficiency rating of 10.8% and an electro-deposited bifunctional nickel iron molybdenum water‐splitting catalyst.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.