Combining ultra-thin layers of different materials can raise the photovoltaic effect of solar cells by a factor of 1,000, according to researchers at Martin Luther University Halle-Wittenberg (MLU) in Germany.

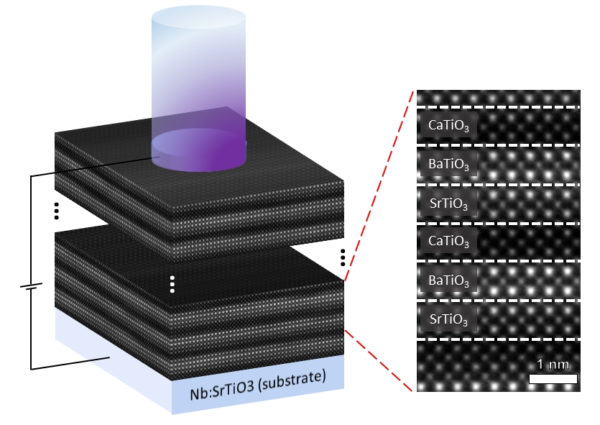

Their findings, published in the journal “Science Advances,” described a lattice arrangement of three different layers of ferroelectric crystals (in this case, of barium titanate, strontium titanate, and calcium titanate) that created a powerful solar energy producing effect.

Ferroelectric means that the material has spatially separated positive and negative charges. The charge separation leads to an asymmetric structure that enables electricity to be generated from light.

Ferroelectric crystals differ from conventional silicon cells in that they do not require a p-n junction to create the PV effect. In other words, there is no need to create positively and negatively doped layers within the cell. The researchers said that change could make solar panels easier to produce.

MLU researchers have been experimenting with barium titanate to take advantage of these properties. However, pure barium titanate does not absorb much sunlight; as a result, it generates a relatively low photocurrent. The research showed that combining ultra-thin layers of different materials can significantly increase a cell’s yield.

Researchers added a thin paraelectric layer to the cell. Although this layer does not have separated charges, it can become ferroelectric under certain conditions; for example, in low temperatures or when the chemical structure is slightly modified.

MLU physicist Dr. Akash Bhatnagar and his team discovered that a much stronger photovoltaic effect occurs when the ferroelectric layer alternates with not one, but two different paraelectric layers.

The team embedded barium titanate between strontium titanate and calcium titanate. This was achieved by vaporizing the crystals with a high-powered laser, redepositing them on carrier substrates. The result was a material made of 500 layers that was only about 200 nanometers thick.

The MLU team irradiated the cell with laser light to test the new material, and the results surprised them. Compared to pure barium titanate of a similar thickness, the current flow was up to 1,000 times stronger, despite the proportion of barium titanate having been reduced by almost two-thirds.

“The interaction between the lattice layers appears to lead to a much higher permittivity – in other words, the electrons are able to flow much more easily due to the excitation by the light photons,” Bhatnagar said.

The studies show the effect is also resilient as it remained nearly constant over a six-month test period. Further research is underway to understand what exactly causes this photovoltaic effect.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

So will these ever be available? Or will this be like “new battery technology” that will never be available??

Currently the technology is in the research phase, and this breakthrough was just recently discovered. The research team is optimistic it will have commercial applications, but it is not at that level of maturity yet.

Well it’s about time the standard 0V model got broken. I used to consult for PV companies their biggest challenge ge was getting enough wafer to process into solar cells. This make all that a thing of the past. The stumbling block will be ramping manufacturing up to commercial scale. Any operation that depends on flash evaporation will be maintenence dependant. They have a lot of work ahead to get the process to scale up. Hire the older semiconductor tech that worked in plasma of thin films they should be able to help the researchers develop tools that will allow mass production. Like I said it will take someone or a team that looks outside the box to improve the tools to be production worthy. The research team has done a great thing with their discovery next step is understanding what it will take to improve the tools and implement changes to make the cells production worthy.

I like This very much and think it will bring a better future global. I leve in Denmark in a campingwagon, try to leve simple coused from more reasons. If i had the money i would by some. But if you would donate some for testning and for. Good couse i would spredd the Word over here for you

1000 times? That means a normal size panel ,area about one square meter, that produces 200 watts , would be capable of an output of 200 kW. I look forward to that. I believe, and this needs confirming, the maximum available power from one square meter is about one kW. What have I misunderstood?

Our apologies for not making this clear. The photovoltaic effect was increased by 1000 times compared to previous output achieved from cells made of ferroelectric crystals, not from prevailing solar cells made of silicon or other conventional materials.

Do we have any idea of how potent is this solar electric generation device ? at the present stage of development .. in terms of watthours per meter square at standard sunlight, or as a percentage of a current generation PERC commercial PV cell ?

No, I gotcha, the FE produces only a low output therefore 1000x improvement may make it feasible, not wondrous

These promos remind me of cures for cancer, etc using stem cells and genetic manipulation – which the public will never see, but it gives them hope…

I believe current market solar panels are on average 15 to 20% efficiency. And can see that 1000x better -is comparison to previous FC’s.

What type of efficiency would these possibly achieve?

25-30? Or better?

Have i waisted my money buying 26 solar panels producing 320 kw per panel about $35,000 after inst.?

It’s a long way from lab to commercialized product!

Would be interesting to know what would be the efficiency on PV panels made with this technology. Currently we are at around 20%. So there is room for improvement.

What is the power output per sq meter? Without this number, the oft repeated 1000x means nothing.

What is the material cost, bearing in mind the high cost of titanium? If it’s only 200nm thick, it should be OK.

What would the mechanical support be that won’t crack under heating cycles?

They probably got it from milliwatts to watts, which is plenty for a research project. The significant report here is not “ferroelectric will now eat semiconductors”, it’s “inserting thin films makes a huge difference in an interestingly different photovoltaic process”.

Any numbers to compare with the efficiency of comercially available panels?

Even at 1000x previous FC capabilities, these still do not exceed PV panels.

Just from the description I can tell why they’re getting the improvement, but it won’t matter as they won’t make viable panel tech in the long run.