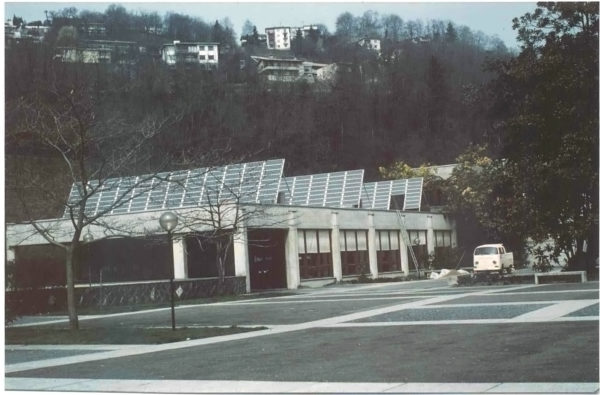

The TISO‐10 (TIcino SOlare) PV system was grid-connected in 1982 on the roof of what today is the SUPSI PVLab at the University of Applied Sciences and Arts of Southern Switzerland, located in the country's Italian-speaking canton of Ticino, where it has operated almost uninterruptedly for almost 40 years.

Measurements of the array’s performance were taken for around 35 years from 1982 to 2017, when the Swiss Federal Office for Energy (SFOE) tasked two scientists — Alessandro Virtuani, senior researcher at the École Polytechnique Fédérale de Lausanne (EPFL), and Mauro Caccivo, head of the SUPSI PVLab itself – and their teams to analyze the huge amount of collected data. “We had to go through an incredible mass of paper and it took almost two years to sort out all relevant information,” Caccivio told pv magazine.

40-year-old panels

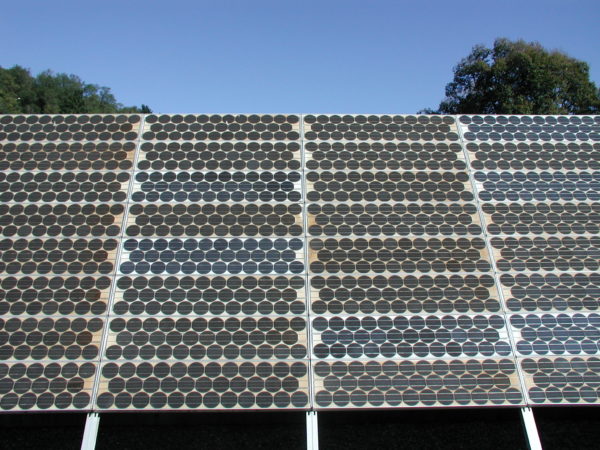

The array was built at a cost of around CHF 284,000 (around $309,000 today and $475,000 at the time) and the 288 modules used for the project cost around CHF 21 ($22.9 currently and around $37 at the time) per watt. The glass-backsheet products, with a power output of 37 W each, were provided by Arco Solar, which was first acquired by German conglomerate Siemens and then by Germany-based solar panel manufacturer SolarWorld in 2007. “When the modules were bought in 1980, Arco Solar was one of the world’s largest manufacturers and had around 1 MW of annual production capacity,” Caccivio specified.

Image: SUPSI PVLab

Although the electrical layout of the system changed several times, following replacements of the inverters, all the modules aged together, always exposed to outdoor environment and sunlight and never refurbished or revamped, with only very few exceptions, in which junction boxes and by-pass diodes were replaced.

“These modules have an impressive mechanical robustness,” Virtuani and Caccivio emphasized, noting, however, that their weight and mechanical dimensions, as well as the thickness of their solar cells, are not representative of what could happen to a solar array in terms of cracks to a PV system built with modules manufactured today or in recent years. “But these modules can tell us a lot about humidity penetration and yellowing,” they stated. “Each panel was encapsulated with a backsheet made of steel foil functioning as a barrier to water ingress, which is sandwiched by Tedlar layers on both sides,” they explained, adding that the product, although it resembles more the structure of a glass/glass panel rather than that of a conventional glass/backsheet panel, is closer to what today we would define as a glass-glass panel.

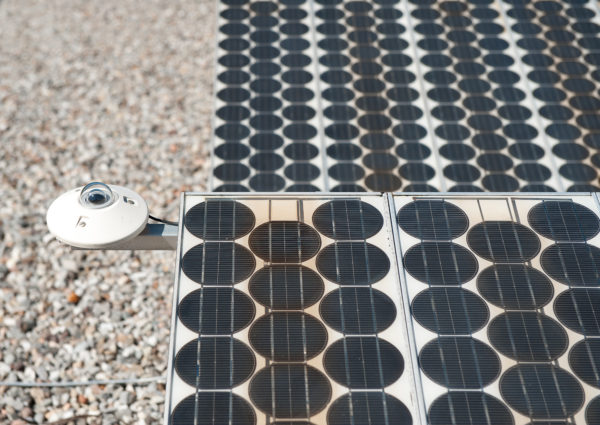

Image: SUPSI PVLab

The 10% efficient modules have an open-circuit voltage of 21.5 V, a short-circuit current of 2.55 A, and a fill factor of 68%. Each of them measures 121.9 × 30.5 x 3.8 cm, weighs 4.9 kg, and is based on 35 monocrystalline cells with a diameter of 102 mm. “Today the cells are much more sophisticated and may include surface passivation layers or more complex patterning structures,” Virtuani said. “This complexity may potentially make cells weaker and expose them to higher degradation rates.”

Overall, the inverters were changed five times. The first devices, which had been provided by Abacus controls, were replaced after 10 years with a new product from Invertomatic and the system design was also modified, with longer strings and the number of modules was slightly reduced. At a later stage, SMA inverters were installed and the system design returned to its original configuration with 288 modules. The solar modules are the only components of the system that have never been changed.

Different yields

The modules’ performance was not the same for all the panels and the researchers were able to divide them into three groups, with the best performant ones showing almost no signs of yellowing, while the other two groups exhibited medium and high levels of yellowing. “In the third group the yellowing was so intense that some panels ended up having a brown color,” Virtuani said. “The long-term electrical performance and aging of the panels is highly correlated to their respective groups and to the behavior of the encapsulant used to manufacture them.”

Chemical analysis performed in recent years confirmed that the three encapsulants are made of the same base polymers but their three respective suppliers used different additives in the encapsulant formulation, explaining the varied performance. “As in many cases with PV installations, the devil is in the details,” Virtuani stated. “By just changing a single element, in this case the supplier of the encapsulant, the entire performance of a PV array can be compromised,” he added. “Which shows that the bill of materials matters. A lot!”

Image: SUPSI PVLab

Due to the fact that extracting the polymers from the module is a destructive technique, the researchers could only conduct the chemical analysis on a limited number of modules, but they excluded other degradation causes, as the yellowing is an issue that relates exclusively to the encapsulant materials. “On the other hand, the modules have shown no signs of humidity penetration,” Caccivio explained.

The three encapsulants were all based on polyvinyl butyral (PVB), a thermoplastic polymer that has been used since the early 80s to encapsulate PV modules and has since been replaced by ethylene vinyl acetate (EVA). “A former Arco Solar manager confirmed that, at the time, the encapsulant is likely to have been PVB and that three different suppliers of PVB were used by the company”, the scientists highlighted.

Three groups

Around 21.5% of the modules showed an annual degradation of -0.2% per year, which should correspond to the value promised by the manufacturer, while another group representing 72.9% of the panels showed an annual degradation of between -0.2% and -0.7% per year. “Most of the panels in the second group have also performed well, meeting initial expectations,” Caccivio stated, noting that this group can be further split into two sub-groups relating to the different encapsulants.

From 1982 to 2017, the modules of the first group degraded overall at most by 13% and those of the second group by up to 21%, although half of them did not exceed the 20% threshold. According to the Swiss group, around 70% of the modules used in the array would still satisfy a performance warranty that module manufacturers are presently considering to apply to the technology of tomorrow, which means a lifetime of 35 years.

The analysis also showed that 87.5% of the module suffered some type of minor front delamination and problems with several junction boxes, but these issues were equally distributed among the three groups. The overheating of the junction boxes, however, had a lower impact on the modules of the first group. Furthermore, some modules showed cracks, backsheet degradation, internal circuit corrosion, hot spots, and burn marks, among others.

The first and most important lesson learned from studying the PV installation and modules “is that bill-of-materials (BOM) matters,” the researchers stated, adding that the choice of materials is as crucial today as it was forty years ago.

Revamping or replacing?

When asked about the future of this PV system and that of aging installations in general, and if revamping or repowering may be a better option than letting old arrays keep generating power, although with lower yields, the two scientists offered different perspectives.

“Economically, it may be preferable implementing revamping and repowering, or eventually replacing the old array with a completely new system,” Caccivio said. “However, the European Commission has established a 40-year lifecycle for the solar modules and, reasonably, we have to use solar products until the end of their lifecycle or until 80% of its original performance is provided.” The studied PV system has shown that a portion of it has lost only 0.2% of its original efficiency and is still abundantly over this 40-year threshold, he added.

Image: SUPSI PVLab

According to Virtuani, it is possible to extend the lifecycle of a PV system by implementing proper maintenance. “If the PV system works out well, it can operate for over 40 years,” he explained. “On the other hand, several business plans, currently, are being developed on a 30-year time frame. But nothing forbids us to extend PV system operation for longer than planned, if the systems and modules are operating well.”

He also said that prolonging the life of a PV system over the 30-year limit may also depend on the applications the PV system has. For example, an array powering a water pump doesn’t need to operate at full capacity and it may probably be used for much more than its owner may expect.

The results of the two researchers were presented in two different papers: “35 years of photovoltaics: Analysis of the TISO‐10‐kW solar plant, lessons learnt in safety and performance—Part 1 and “35 years of photovoltaics: Analysis of the TISO‐10‐kW solarplant, lessons learnt in safety and performance—Part 2,” which were both published in Progress in Photovoltaics.

This article was amended on 05/07/21 to reflect the panels have a short-circuit current of 2.55 A, rather than 2.55 V, as previously stated.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

If I did the test, I’d have reported the trend in annual kWh or at least its kWh/kWp (specific annual yield). That’s what matters most to an investor. Reporting module-only degradation and binning it is interesting, but it obscures (deliberately?) the fact that non-uniform degradation creates mismatch at a system level and therefore makes degradation substantially worse from an owner’s standpoint. Also, I would have run some samples through a UL listing or equivalent sequence to see if these aged modules would be deemed safe enough to sell. If not, they aren’t safe to use, regardless of the wishful thinking of the study’s proponents. The system should be isolated from touch hazards, but even more so than a normal system would be safeguarded. It’s a great study, a necessary one, but when all of the j-boxes and diodes have failed, and of course the inverters, and there is widespread indication of delamination, corrosion, and cell cracking, it seems irresponsible to conclude and convey that PV is a 40-yr product. This is the last thing that the industry should be saying about itself. As a last point, Siemens Solar became Shell Solar before it became Solar World Americas, and even it has subsequently become a Sunpower acquisition, as I recall.