Scientists in China have developed a direct-drive photovoltaic air conditioning system that can store solar power through ice thermal storage. The latter is common thermal storage technology based on standard cooling equipment and an energy storage tank that is able to store cooling while shifting energy usage to off-peak, nighttime hours.

“The novelty of this work is that a solar cooling system directly driven by distributed PV is proposed and the rechargeable storage battery is replaced completely by low-cost ice,” research-co author Guoliang Li told pv magazine. “Solar air conditioners with different sizes of PV panels, with and without MPPT controller and different types compressors were built and tested outdoors to experimentally investigate the running characteristics of air conditioning at various solar irradiations.”

PV-driven air conditioners, according to the research group, are often equipped with batteries for energy storage and this results in challenges of low performance, high initial investment, and complex configurations for practical applications. “The ice thermal storage for the PV driven air conditioner with reduced batteries was explored in our previous work,” it explained. “It proved the feasibility of the ice thermal storage, where the batteries were only used as a buffer and the system average energy efficiency could reach 7.65%.”

The proposed new system consists of: A PV system built with 12-16 monocrystalline modules with a power output of 190 W mounted with a tilted angle of 30 degrees; a control system based on an inverter and an MPPT controller; an ice-making system comprising a variable-speed compressor with a frequency range of 360 Hz; a condenser; a liquid storage device; a capillary; an evaporator; an ice thermal storage tank; a gas-liquid separator; a variable speed pump; and a heat exchanger.

The performance of the system was evaluated considering operating efficiency and stability. “The optimal matching relationships were found and experimental results of the system with variable speed compressor and an MPPT controller have shown very good ice-making capability and reliable operation as well as a great improvement in the available photovoltaic power,” Li stated, noting that the average PV-to-compressor power efficiency (PPE) and coefficient of performance (COP) of the systems were improved by reducing the power ratio, which in turn reduced the operation stability ratio (OSR) of the compressor.

Through their analysis, the academics found that the use of an MPPT controller improved the PPE of the system by 81.7% compared to that of the system without MPPT, and that the variable-speed compressor was more adaptive for the PV-driven cooling.

The proposed system is presented in the paper “Study on matching characteristics of photovoltaic disturbance and refrigeration compressor in solar photovoltaic direct-drive air conditioning system,” published in Renewable Energy. The research group includes scientists from the Yunnan Normal University and the Jiaxing University.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Regarding the pv ice storage.

Is there anyof these systems in operation outside the lab?

I have a friend made it 4 years ago and still working but not with solar power.just a normal ice storage .

It is working in 16 place yet

At MIT a 365 day thermal flywheel environmental control system was constructd for one of the engineering buildings decades ago. It cut the cost of environmental thermal management by something on the order of 85%.

I build an ice storage system several years ago that is still working well. I build it to take advantage of off peak power rates, I make ice at night when the power rates are less and the outside ambient is lower which improves the compression ratio. My house and yard have to much shade to go to solar drive.

I am a retired refrigeration tech and had no trouble designing and build the system. Going to solar would be just as easy, a solar vfd drive with controller and a permanent magnet dc drive motor.

I too am retired from the HVAC and refrigeration trade. 35 to 40 years ago I worked for the oldest Carrier dealer

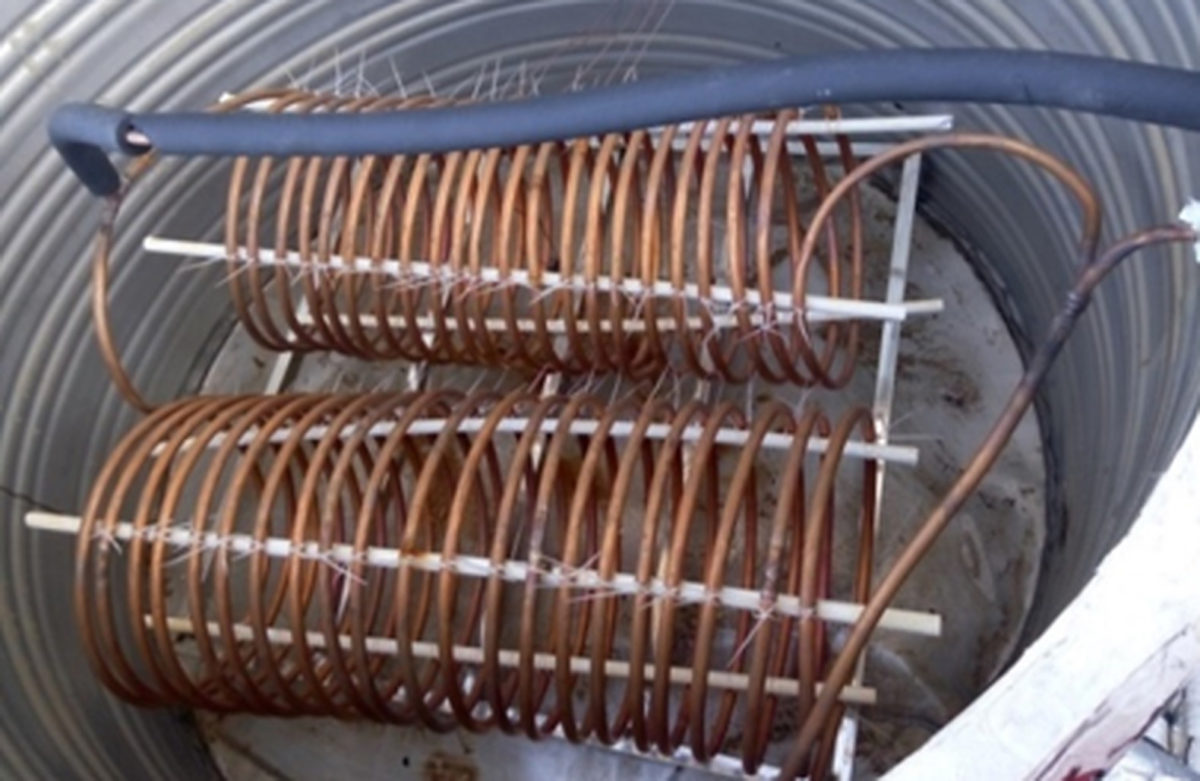

in dallas, tx. We used to go into the basement of churches and build a 20′ long x 8′ wide x 6′ deep tanks out of sheet steel weld them up and weld 1″ surpentine coils approximately 100′ from black iron pipe. we would install 6 coils standing up in the tank with 5 ton TXV’s on each coil. we would use a 5H40 carrier compressor using R12

as the refrigerant.

The compressor would start mid-afternoon on saturday and run all night. By sunday morning ice had formed on the coils 6 to 8″ in diameter and the circulating pump would start sending 33 to 35 degree F. water to the air handler. this cold water would pull a LOT of condensate out. it was said that 160 to 200 tons of cooling were available from this system. it was cold enough that many of the worshipers wore sweaters in there in the middle of the summer!!!

I would like to build an ice tank at my house using r134a and need some guidelines for evaporator sizing and tank sizing for my residence for 24 hours of storage. i am planning to run my condensor(s) for 8 to 10 hours during off-peak rates from my electricity provider. any help with sizing would be appreciated.

Hi Jake, I’m a dairy farmers the UK, I have milk that requires cooling, I have south facing roof space that I cannot utilise for solar because the local energy network won’t let me. I have an existing ice builder to provide cold water for cooling milk through a heat exchanger. This ice builder doesn’t have enough capacity to store ice so the compressors run all day. I want to try an off grid system to build ice when the sunshines, ice will be stored in a new ice bank and linked to the existing system only by circulating cold water through it. I just need a little guidance, any ideas?