Backsheet failures in solar panels are a reasonably common occurrence and affected panels frequently require replacement in a process which has involved lengthy legal battles and severe engineering challenges. DuPont Photovoltaic Solutions, though, has now brought to market a solution which promises an easy fix – a Tedlar-based band-aid for modules.

The materials supplier estimates that, in Europe alone, about 6 GW of solar capacity is affected by backsheet failures. After years of service in humid or dry, hot or cold conditions, and under severe UV-light irradiation, backsheet materials can suffer from defects, with some materials more susceptible than others. If backsheet failure reaches a critical stage, the film begins to crack, exposing the rear of the semiconductor. That can lead to leakage currents and isolation faults in the system, which will trip the inverter and shut down the array. In such cases, service teams have to make site visits to switch arrays back on, adding expense and loss of income to a site owner's costs.

In the past, modules suffering in that manner had to be swapped, which may be no easy task if the power class of the new module needs to be the same as that of the device it is replacing. If voltage or current differs on a replacement panel, it cannot simply be integrated into an existing string and new electrical layouts need to be made, which involves planning and engineering work.

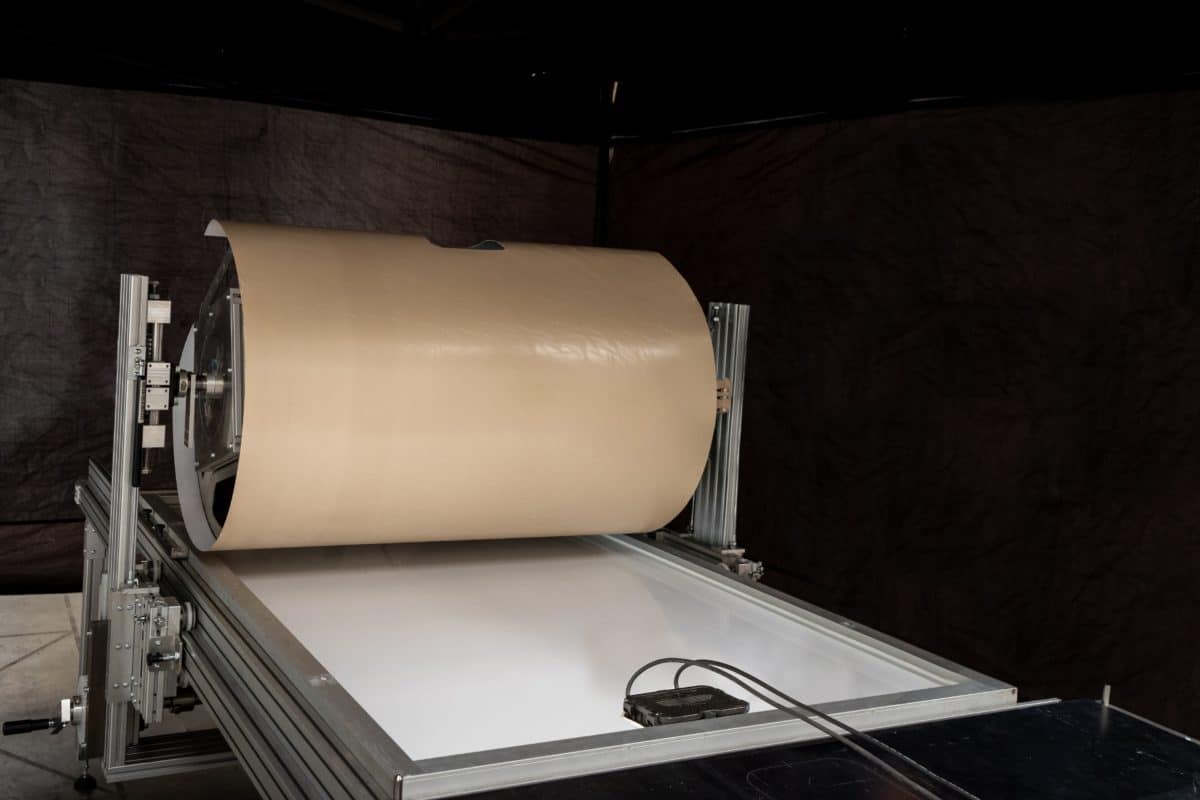

DuPont has come to the rescue with its PV Rescue Tape, at a fraction of the cost of panel replacement. The material is a Tedlar-based backsheet that comes with butyl rubber adhesive. Faulty modules can be dismounted in the field by a trained service group from Sc-refit GmbH, an affiliate of Suncycle GmbH. The service crew can fit the new backsheet onto the module using a proprietary tool or there is the opportunity of sending modules to Sc-refit’s repair centers.

“We are delighted to be partnering with DuPont to support this much-needed solution for the PV market,” said Sc-refit chief executive Roberto Gacitua. “There is great demand from both module manufacturers and asset owners for repair products which can help extend the usable lifetime of solar panels. Our specialized repair process, customized for Tedlar PV Rescue Tape, reduces costs versus a full replacement of affected panels. It also helps to improve overall returns on investment of solar assets, making it a win-win solution for everyone involved.”

The solution can be applied to any type of backsheet and is designed to stick to severely cracked surfaces. Sc-refit will commercialize the solution in Europe. The partner will accredit and operate a network of service partners to accommodate rapid deployment of the product.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

How would that adhesive go in the Australian sun/heat?

One important question:

How about the certification of the repaired panel? After “repair”, the module is altered, therefore the original certification is not applicable anymore. How is Dupont handling this, escpecially for the IEC 61730?

Where can I find this repair sheet as a DYI repair