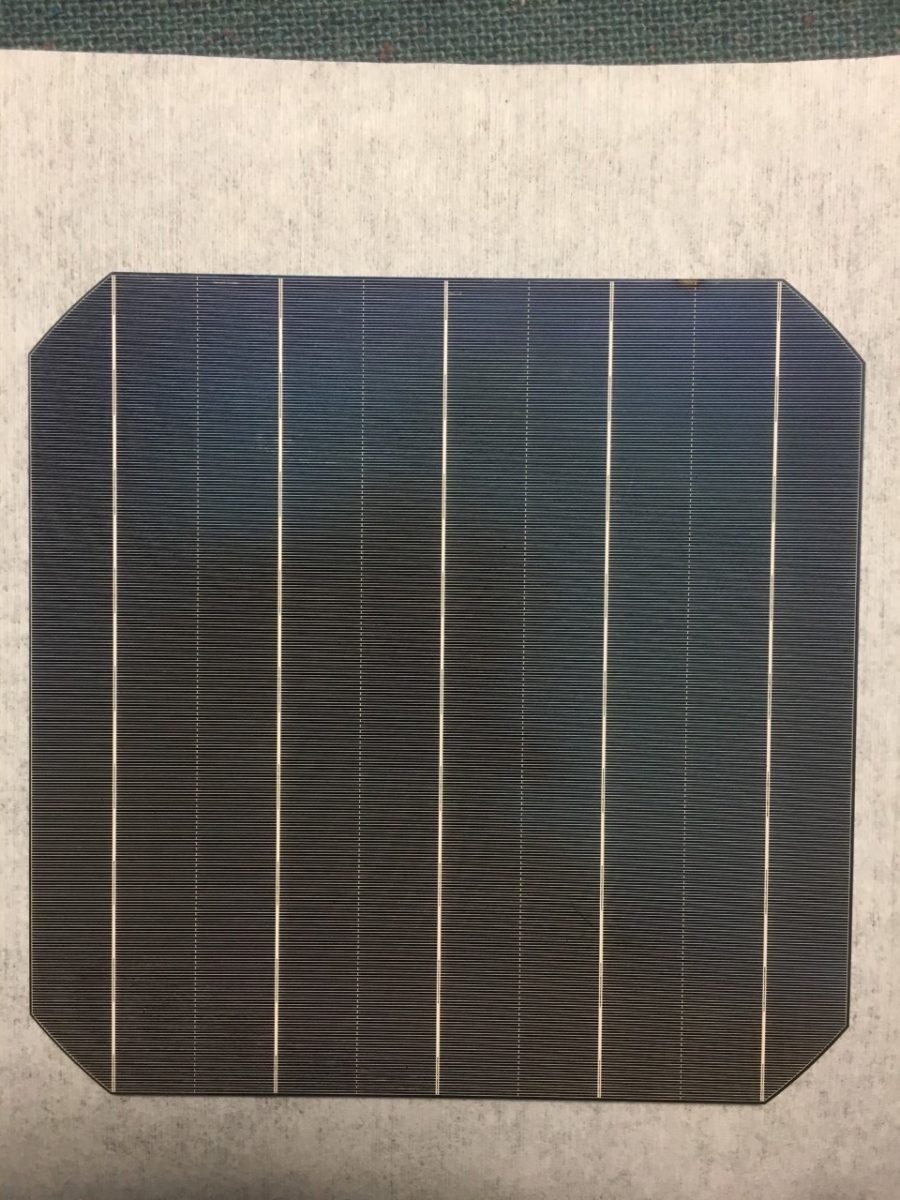

A group of scientists at the Georgia Institute of Technology in the United States has fabricated a screen-printed bifacial n-type silicon solar cell with a large area of 239 cm².

The device was built with an ion-implanted homogeneous boron emitter on the front side and a carrier-selective tunnel oxide passivated contact (TOPCon) on the rear side. “The cell was developed using commercial tools,” research co-author, Young Woo Ok, told pv magazine. TOPCon is currently being investigated by major manufacturers as a route to efficiencies beyond 25%, but higher costs compared to PERC have limited its development so far.

The passivated contact was implanted through low-pressure chemical vapor deposition (LPCVD) on the rear side of a 180 micron thick Czochralski wafer. “Since LPCVD grows poly-Si on both sides of the wafer, we implemented a masking process to etch poly-Si from front side,” the academics explained.

The cell was then annealed at 855 degrees Celsius for polysilicon crystallization and dopant activation and the boron emitter was passivated by atomic layer deposition (ALD). Silicon nitride masks were applied on the cell's edges to protect them during the process.

Fully screen printed cell

The front side metallization was made with floating busbars (FB) using dual-print. The grid fingers were screen-printed with a fire-through paste made of silver and aluminum, and the busbars were then printed with a non-fire-through silver paste to prevent damage to the cell layers. The sample was finally fired in an industrial-style belt furnace at a temperature of 770 degrees Celsius and, at the end of this process, the protection masks were removed.

Tests conducted on the cell showed that it reached a maximum efficiency of 22.6%, an open-circuit voltage of 702 mV, a short-circuit current of 40 mA/cm2, and a fill factor of 79.7%.

The cell was described in the study Fully screen-printed bifacial large area 22.6% N-type Si solar cell with lightly doped ion-implanted boron emitter and tunnel oxide passivated rear contact, recently published in Solar Energy Materials and Solar Cells.

This comes the same day that manufacturing giant Longi set a new record for n-type TOPCon cells at 25.21%. However, in another study published more recently, the U.S. group investigated optimizations to doping profile, surface concentration, recombination current density, and sheet resistance of the ion-implanted boron emitter. Through simulated results, it raised the cell efficiency to 22.9% and concluded that, with busbarless contacts, the device may also achieve an efficiency of 23.5%.

TOPCon Under Pressure

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.