U.K. researchers have proposed to use the airflow generated from compressed air for the simultaneous cleaning and cooling of solar modules.

They utilized a mathematical model to analyze how dust adhesion on the PV panels' surface is removed through the airflow and how the air had, also, a positive impact on the panel operating temperature. These findings were used to build a pilot cleaning and cooling system based on a compressed-air unit which was made of a compressor, an air tank, and an airflow regulation valve, and a series of nozzles with a thickness of 5mm. All components, according to the research team, are low-cost and standardized products.

“The compressor is directly powered by the PV panels and the release of the compressed air from the tank is regulated by the valve to meet the mass flow requirements of cleaning and cooling,” the scientists explained. “The spreading air from the nozzles installed at the edge of panels overlaps and forms a flake shape airflow then carries away the dust and heat from the panel surface.” Air can be transmitted over the panels through a pipe assembly that can be moved across an installation to clean and cool its parts when it is more needed.

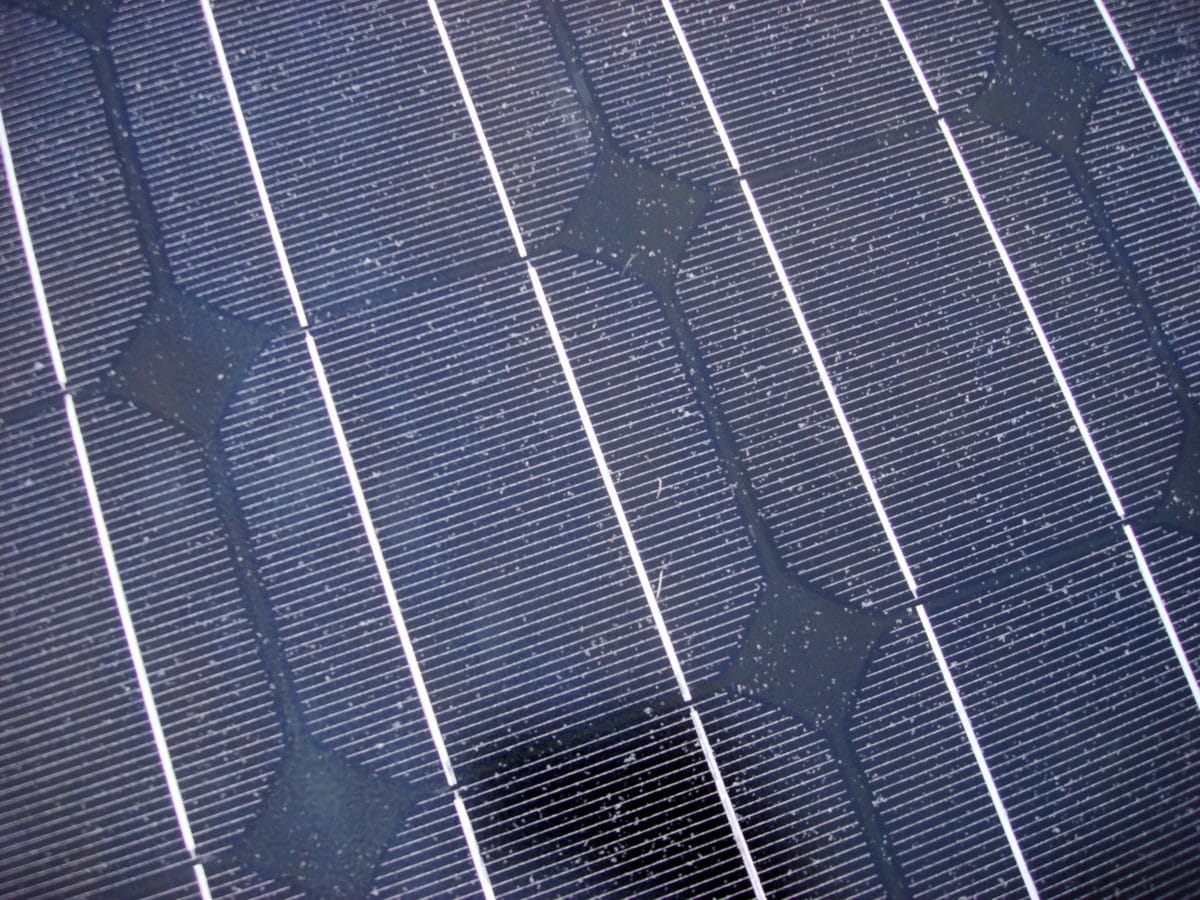

The British team tested the system on a PV system relying on monocrystalline PV panels operating in an unspecified area of northwestern India. “The average size of the dust deposited on the panel surface was 20µm and almost 90% of particles had diameters less than 30µm”, it specified. “The tilting angle of the panel was set to 30 degrees and the average temperature of the surface can reach up to 333 Kelvin.”

After two weeks of testing, the panel surface was covered by 5.3g of dust, which reduced its power output from 42.5 to 37.5 W at 303 Kelvin. After cleaning operations were implemented through the airflow injected by two nozzles, the power output of the module returned to an average of 41.82 W. The experiment also showed that, at a temperature of 333 Kelvin, the module's yield dropped to 28.24 W while, after 130 seconds of airflow, the temperature fell to 315 Kelvin and the power output increased to 32.42 W.

The blowing time was then set as 10, 15, and 20 seconds and the power output of the tested PV systems increased, from 567.4 W, by 30.7%, 33.6%, and 36.1%, respectively. The cooling effect, however, may only be obtained for short periods of time during the cleaning operations, as the costs for producing the airflow are higher than the benefits achieved by long cooling operations. “Therefore, the blowing time and specific particle size for removals need to be determined, considering the optimal balance between energy consumption in compressing air and energy gain from PV performance improvement, for the application scenario studied,” the academics asserted.

In further research, they want to investigate nozzle configuration, frequency and time for cleaning operations, and how to integrate maximum power point tracking (MPPT) under different dust deposition rates and PV module temperatures.

All the details of the system, which is described as an ideal solution for arid climates, can be found in the paper Study on the cleaning and cooling of solar photovoltaic panels using compressed airflow, published in Solar Energy. All the researchers come from the University of Warwick, in the United Kingdom.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.