Though solid-state batteries have caught the attention of the energy storage industry, their commercial application has so far been very limited, and there is a wealth of different potential materials to replace the liquid electrolytes used in today’s lithium-ion batteries in various stages along the path of scientific investigation and potential commercialization.

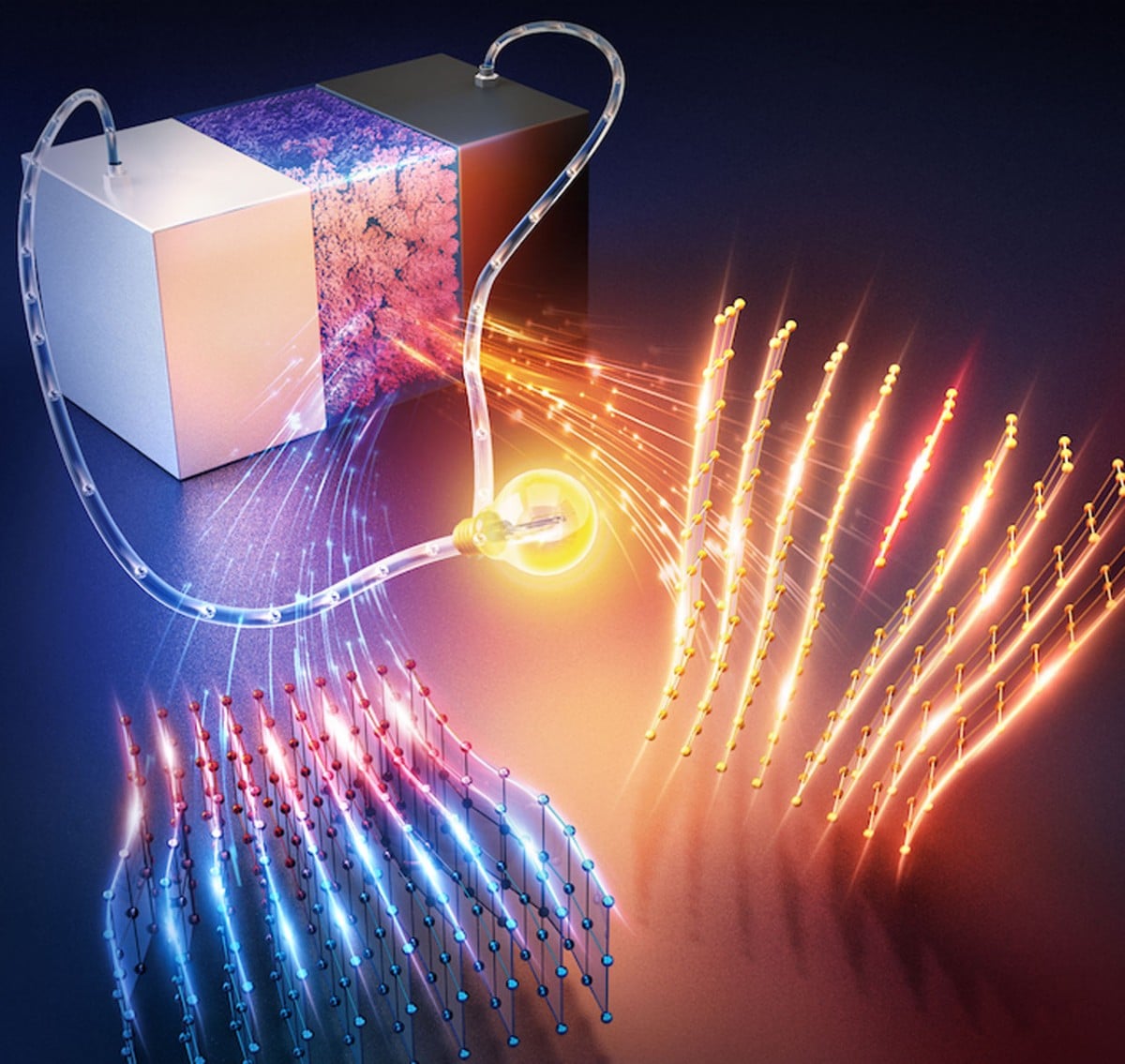

Scientists led by Cornell University in the U.S. took a closer look at one such material, enabled by the latest imaging techniques conducted at Argonne National Laboratory’s synchrotron light source facility, the Advanced Photon Source.

The group worked with a sample of aluminum-doped lithium lanthanum zirconium oxide (LLZO). Although oxide materials are thought to be more challenging than sulfides or polymers in terms of commercial production, oxides also have potential. And the Cornell researchers state that LLZO has shown promise with high ionic conductivity and good stability properties.

Crystal defects

After synthesizing a sample of LLZO, the group headed to the Advanced Photon Source where they employed a technique called Bragg Coherent Diffractive imaging, to shine an X-ray beam onto a one-micron sized grain of the material and create a 3D image of its inner structure. Full results of this experiment can be found in the paper X-ray Nanoimaging of Crystal Defects in Single Grains of Solid-State Electrolyte Li7–3xAlxLa3Zr2O12, published in Nano Letters.

“These electrolytes were assumed to be perfect crystals,” said Cornell researcher Yifei Sun. “But what we find are defects such as dislocations and grain boundaries that haven’t been reported before.” The work further that process of doping the material with aluminum was responsible for many of these dislocations and boundary, and could inform the future development of solid-state batteries.

The group is now planning further research to understand how these defects affect the mechanisms at work in the battery as it charges and discharges, and also whether they can control the growth of these defects to gain a further advantage. “Now that we know exactly what we’re looking for, we want to find these defects and look at them as we operate the battery,” said the group’s senior scientist Andrej Singer. “We are still far away from it, but we may be at the beginning of a new development where we can design these defects on purpose to make better energy storage materials.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.