A group of scientists from the Mälardalen University in Sweden is investigating how to optimize electricity yield in agrivoltaic installations with vertically mounted bifacial PV modules.

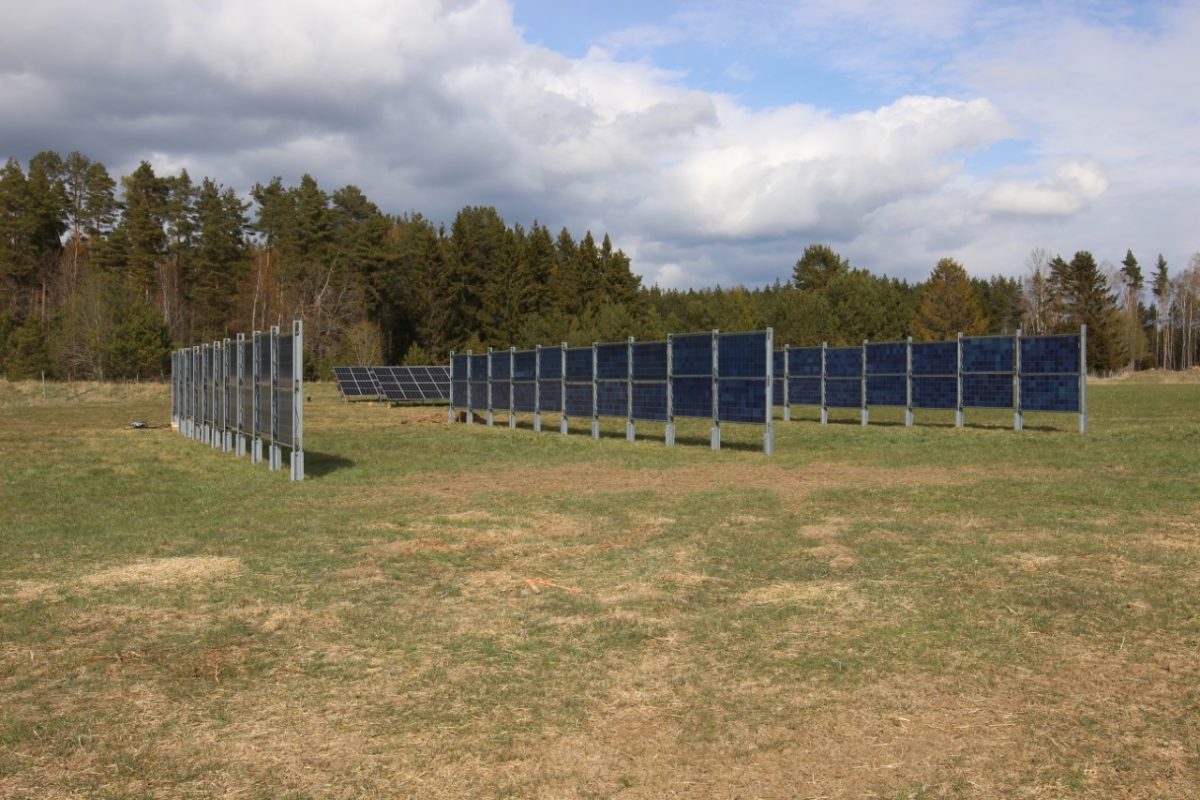

“Vertical bifacial agrivoltaics were chosen in this project because we believe it is one of the agrivoltaic configurations that is easy to integrate and scale up in farmland; it is a cost-effective mounting structure, and provides easy access for types of machinery used in farmland,” researcher Pietro Elia Campana told pv magazine. “Moreover, it is difficult today to get permission to build solar parks on agricultural land in Sweden, and our hope is that agrivoltaics will open a completely new market,” said researcher Bengt Stridh.

The scientist developed a techno-economic optimization model that is claimed to be able to outline the ideal design parameters for an agrivoltaic vertical PV system by combining climatological data with figures on expected solar power generation, shading distribution, water for irrigation, and agricultural yield. The proposed model takes into account, in particular, how much photosynthetically active radiation (PAR), which is the portion of the light spectrum utilized by plants for photosynthesis, is received on the crop.

The model is based on OptiCE, which is an open-source modeling and optimization package for clean energy technologies. The package contains algorithms for calculating the solar position, decomposing solar radiation, analyzing shadings, calculating evapotranspiration, modeling crop growth, and optimizing the system design considering techno-economic aspects. The optimal system design is attained, the researchers claim, through a bio-inspired optimization algorithm that performs hourly dynamic simulations of the entire water-food-energy interrelationships in agrivoltaic systems.

One of the key parameters that the model seeks to determine is the optimal distance between the solar module rows depending on the kind of crop. For example, the research group found that 9 m could be an ideal distance when oats are cultivated and 8.5 m is the most suitable distance for potatoes at the selected location in Sweden, which means crop planting should be thoroughly planned through multi-year and multi-crop simulations when crop rotation must be implemented.

A further simulation has been performed for pasture grass, the kind of crop grown underneath the first agrivoltaic system in Sweden, and the optimal distance was 9 m. “We are waiting for the results generated by the demonstration site to validate and calibrate the model,” Campana explained.

The row distance, according to the researchers' findings, has an impact on PAR distribution and — at the latitude of the investigated location and as a consequence — crop yield may be more than halved when the row distance is reduced from 20 to 5 m. The potential PV production can be reduced by about 20% when the row distance is similarly reduced from 20 to 5 m.

The optimal distance is a result of a techno-economic mathematical problem to find the trade-off for maximizing the land equivalent ratio, which means maximizing crop yield and electricity production per area. Nevertheless, the optimal distance also depends on the width of the tractors and types of machinery that are typically used by the farmers, which means the row distance has to match the width of the agricultural equipment and practices. Distances close to or higher than 20 m produce a negligible effect on the crop yield. This, however, has three disadvantages, according to the research group. The first is that the land equivalent ratio is lower and the second is related to the infrastructural costs of the PV system that become higher. “And last but not least, we want to make agriculture more resilient to temperature stresses and drought by exploiting the shadings on the crops and this effect does not occur at high row distances,” Stridh specified.

The model is being tested on a simulated 22.8 kW vertical installation located in Sweden and relying on 380 W n-type bifacial modules provided by Chinese manufacturer Jolywood with a bifaciality of around 80%. Bifaciality is commonly defined as the ratio of the output measured from the rear side of a module over the output measured from its front side.

With their calculations, the scientists also concluded that orienting the azimuth angle towards east and west, rather than south, may help minimize power fluctuations. “This avoids having a high peak of power production at noon by instead having lower peaks in the morning and in the afternoon,” Campana affirmed. “It also reduces the peak power injected into the grid and matches better the electricity consumption of the farm, thus leading to a higher PV self-consumption.”

The research project is being financed by Swedish energy agency Energimyndigheten, with the Swedish University of Agricultural Sciences, Solkompaniet AB, and Kärrbo Prästgård AB as project partners. The Swedish Meteorological and Hydrological Institute, Uppsala University, Universitá Cattolica del Sacro Cuore in Italy, and the US' NASA ARC are participating as scientific collaborators.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Good to know the “world” is waking up to AgriVoltaics (AV).

This Solar Energy Option is the only one (I know of) that can provide ALL the Energy one needs using only a fraction of the Agricultural Land (~7%… or 1 Million km2 of 15Million km2 of Farmland Globally)…

All explained in You Tube Channel zeropollution2050 (ond word)…