Improvements in one area of a PV system often place new requirements on another, as has been demonstrated in the past year by the rapid rise of larger silicon wafer formats.

For anti-reflective coatings (ARCs), now widely applied to frontside glass during module production, emerging tandem and multijunction cell concepts present a new challenge. These cells are tuned to absorb a larger range of the solar spectrum, meaning more work for the ARC to minimize reflection across a wider range.

Scientists at the Polytechnic University of Madrid sought to get ahead of this issue, analyzing the role of ARCs in some of the III-V multijunction cell concepts already in use for niche applications such as powering satellites and space exploration. Their full investigation is published in the journal Solar Energy, under the title High-low refractive index stacks for broadband antireflection coatings for multijunction solar cells.

In the paper, the group notes that recent approaches to improving ARCs often include the addition of extra layers to the coating, or the use of complex nanostructures or plasmonics to form the coatings – all of which add more complexity and material consumption to the manufacturing process.

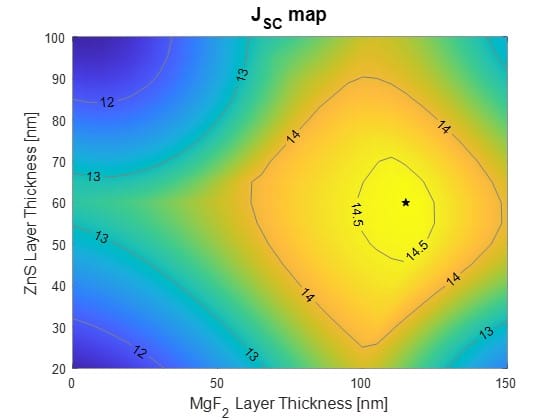

With this in mind, the scientists stuck to approaches that rely on combinations of just two materials – pairs of thin layers alternating between materials with high and low refractive indices. The group has developed an algorithm to calculate optimal coating designs for two different types of III-V solar cell, and demonstrated that the high-low refractive index combination can lead to significant improvements in cell efficiency.

In simulations with various cell technologies, this approach showed efficiency increases between 1 and 5% attributed to the coating design. In comparison to processes currently used to deposit ARCs on multijunction solar cells, the group also notes several potential advantages in mass production for its ‘High-Low Refractive Index Stacks’ approach, which it says has already been implemented for glass coatings in other industries, and that equipment currently used in PV could be adapted.

“The advantage of HLIS ARC is that only two materials are used which reduce the demand of new materials compared to a multi-layer step down ARC (e.g. triple or quadruple layer ARC),” the scientists conclude. “This simple technical solution together with the fact that HLIS seem to be largely immune to small variations in step thickness show promise for their practical applicability.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.