Scientists at the Massachusetts Institute of Technology have proposed a new approach to identify the best perovskites for solar cell applications, depending on specific goals such as longevity, efficiency, and producibility, as well as the availability of source materials that the manufacturers aim to achieve.

The scientists presented their findings in “A data fusion approach to optimize compositional stability of halide perovskites,” which was recently published in Matter. They described the approach as a physics-constrained sequential learning framework to identify the most stable alloyed organic-inorganic perovskites.

The U.S. researchers said that perovskites include a wide range of materials that differ from each other by the way in which atoms are arranged in their layered crystal lattice. These layers, which are commonly described as A, B, and X, can each consist of different atoms or compounds.

“If you consider even just three elements, the most common ones in perovskites that people sub in and out are on the A site of the perovskite crystal structure,” said researcher Tonio Buonassisi, adding that these elements can be varied by a 1% increase in their relative composition. “The number of steps becomes just preposterous. It becomes very, very large and thus impractical to search through systematically.”

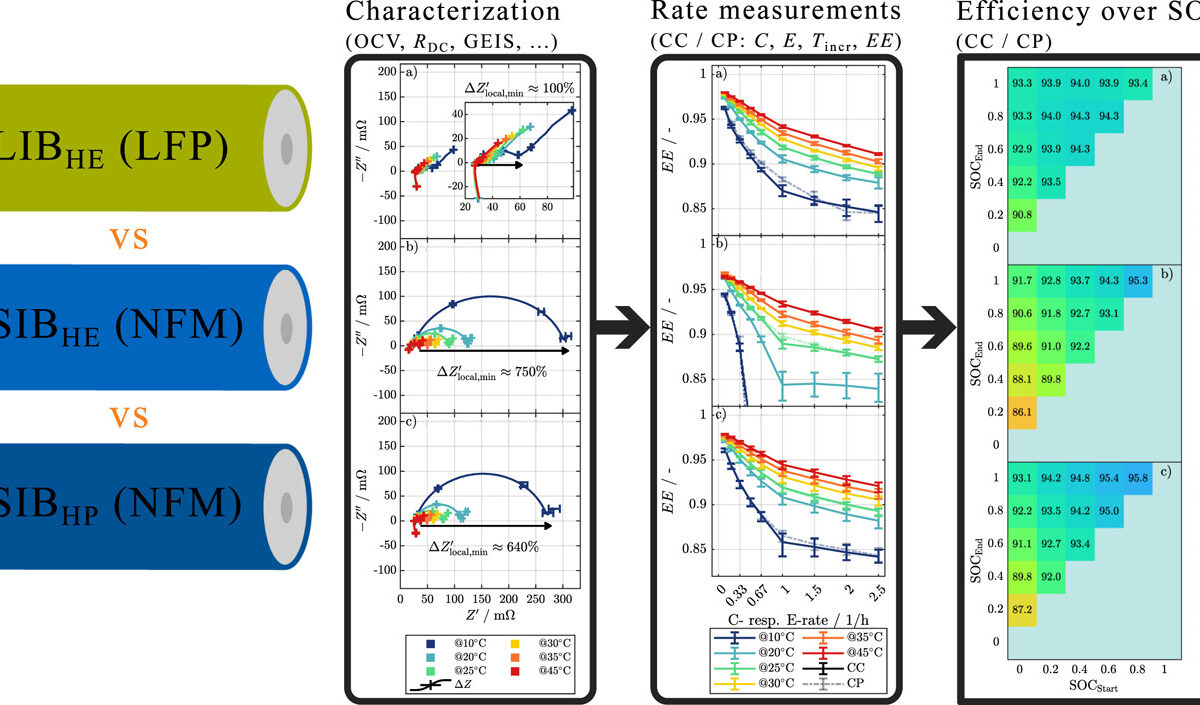

The proposed method, which is based on machine learning, combines data from different sources in a data fusion approach. It uses an automated system to guide the production and testing of a range of perovskite formulations and then combines the results with first-principles physical modeling, to guide the next round of experiments. The scientists repeat this process several times until the results are refined.

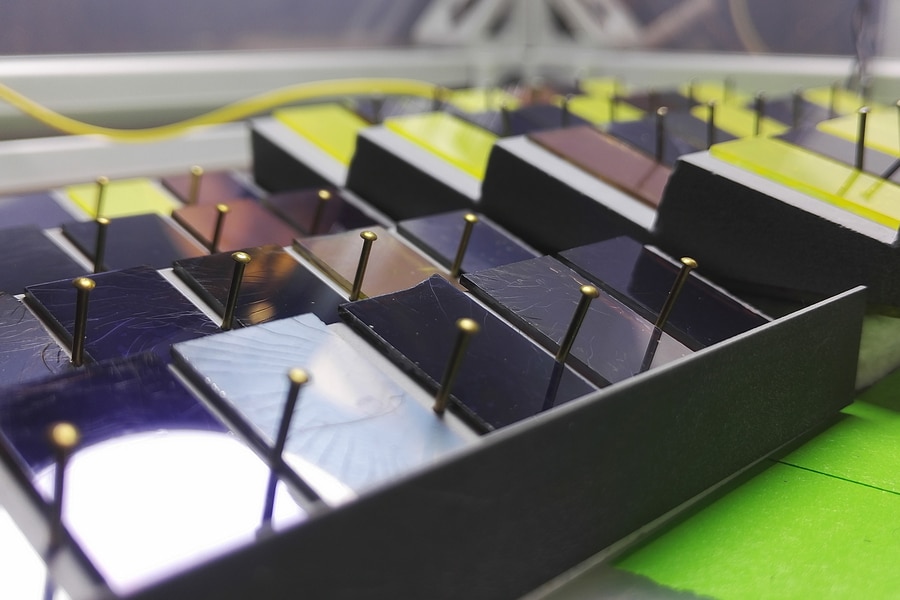

Thus far, the group has synthesized and tested around 2% of the possible combinations among three components. The scientists claim they have already identified the most durable formulation for perovskite solar cell materials to date. With this material, they also fabricated a small chip and placed it into an existing solar cell, and discovered that it can ramp up the device's stability by more than three times, without compromising its power conversion efficiency.

“Another point of this work is that we actually demonstrate, all the way from the chemical selection until we actually make a solar cell in the end,” said researcher Shijing Sun. “And it tells us that the machine-learning-suggested chemical is not only stable in its own freestanding form. They can also be translated into real-life solar cells, and they lead to improved reliability.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.