From pv magazine 03/2021

Flexible thin-film solar has long attracted interest, both academic and commercial, for its potential to transform what we think of as a solar panel today. Lightweight devices, easy and cheap to manufacture in a variety of forms, can be bent and shaped for integration into the built environment, or even vehicles. These approaches could have an important role to play in our energy future.

So far, flexible thin-film solar has remained a niche area, with efficiencies and device lifetimes a little behind those achieved in silicon PV or thin films deposited on glass. Several companies though are working with different cell materials – primarily perovskites and copper-indium-gallium-selenide (CIGS) – and manufacturing that relies on printing processes already well established in other industries, promising low production costs.

In the United Kingdom, one producer working on an innovative flexible thin-film PV solution recently reported that it had received several investments over the past few months amounting to GBP 5.8 million. It now plans to have a pilot production line up and running in the north of England in the second half of 2021.

Flexible substrate

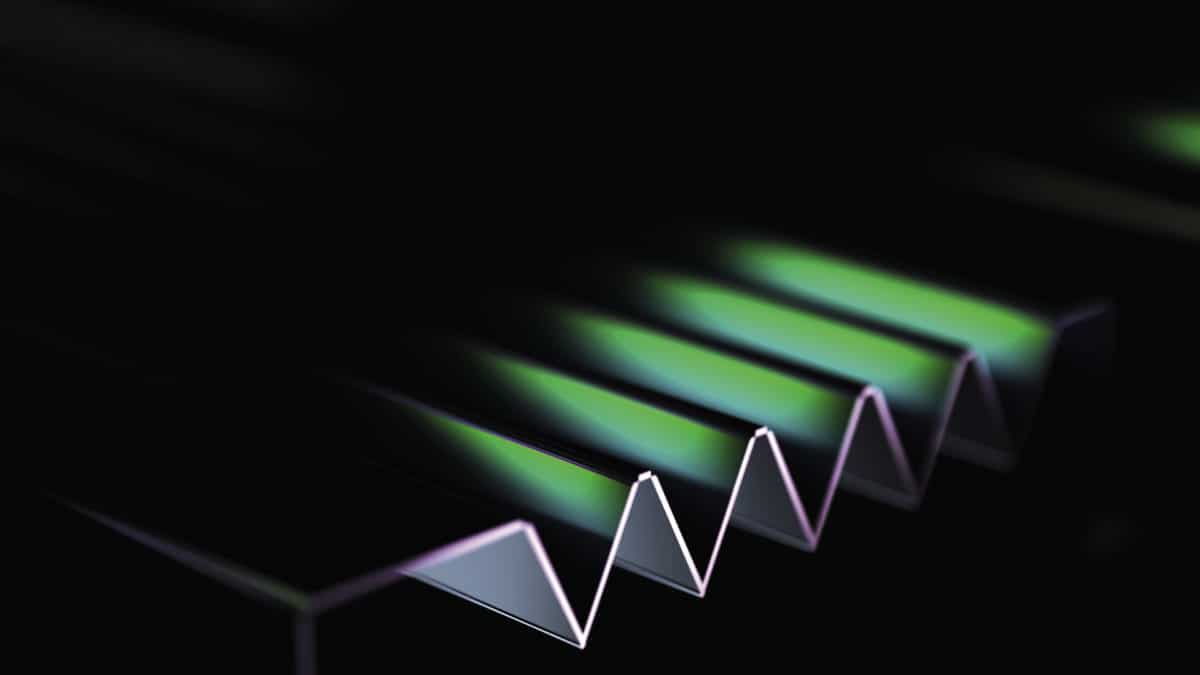

Power Roll’s innovation begins at the flexible substrate. It is currently working with polyethylene terephthalate, but says it could potentially use a range of other materials. The substrate is embossed with an acetate structure of “microgrooves,” each just a few micrometers thick.

With this embossed substrate, Power Roll first deposits transport layers onto the sides of the grooves using a vacuum cooling process, and then a photo-active cell material is printed onto the surface using roll-to-roll, slot-die coating. In pilot production, the company plans to work with a perovskite as the cell material, though potentially it could make use of any other solar-absorbing ink compatible with the printing processes. Each of the microgrooves acts as an individual solar cell. Small devices, measuring around 10×10 cm, on a film less than 0.5 mm thick, contain several thousand cells divided into several hundred modules. This means that any device would have strong resistance to shading or small area defects. Finally, the device is encapsulated to protect its inner workings.

The concept was first developed by Alexander John Topping, Power Roll’s chief scientist. Topping combined his experience gained working on coatings solutions in both stealth technology for defense applications and in the food packaging industry to come up with the microgroove concept for solar film manufacturing.

Though it has yet to produce the film at any scale, Power Roll estimates that with this design it will be able to manufacture PV devices at a cost of around $0.03/W. “There are a lot of costs that we take off the table. We don’t need a transparent conducting layer, we don’t need any complex cell interconnection features,” Power Roll CEO Neil Spann told pv magazine. “We’re looking to manufacture the film at a fraction of the cost of other technologies on the market, so the economics are very exciting.”

Working with the perovskite ink, Power Roll’s current cell efficiency is 11%. By the time it begins pilot production, targeted for September this year, the team expects to push this up to around 15%. And the company has a roadmap to go to 20% and perhaps beyond, through optimization of the vacuum deposition and printing processes, rather than engineering of the cell material itself.

Power Roll’s approach offers scope for flexibility in the size and shape of devices. Initial plans in pilot production are for a 150-mm-wide film, eventually moving up to 300 mm. And the length can be decided by the application. “The first application areas we’re looking at are non-load bearing rooftops and buildings as a whole,” said Spann. It is exploring other applications in portable PV and temporary structures, as well as polymer greenhouses and the agrivoltaics space.

Potential pathways

By printing a dielectric material, rather than a solar absorber, onto a similarly microgrooved substrate, Power Roll has also successfully manufactured a capacitor film. It has begun a joint venture with a company in India, which also plans to begin manufacturing in the second half of this year.

Further into the future, the potential to combine these two approaches, and to move beyond the capacitor into higher energy storage territory, could offer some exciting prospects. Depositing a solar absorber on one side of a film, and a capacitor/energy storage material on the other, would create a single device that can both generate and store solar energy.

This would require new developments in energy storage, particularly in printable storage materials, but it is something that’s already on Power Roll’s radar. “We’re reaching out to companies that have storage materials we could potentially deploy into our architecture,” said Spann. “It’s very interesting, and something we are putting some resources into. Our primary objective though is to get both the solar film and the capacitor into the market.”

Combining the solar film and the capacitor, meanwhile, could store a smaller amount of energy within a solar device. And Spann sees output smoothing or replacing batteries in lower energy devices, like Internet of Things sensors, as further potential pathways for Power Roll’s versatile technology.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.