Electric cars incorporating PV panels on their bodywork or roof have the potential of reaching more than 10,000 km per year of pure solar-powered driving and the modules could have a payback time of only three or four years.

This is one of the main preliminary findings of a research program for vehicle-integrated PV that is being run by Bonna Newman, program manager for PV and Mobility, Module Technologies at the Netherlands Organization for Applied Scientific Research (TNO). “We have developed a model to quantify all the benefits that are generated by installing solar panels on electric vehicles,” she told pv magazine. “We want to look at how much PV power can really be expected to be generated in different situations.”

The program includes exploring crystalline silicon, thin-film and perovskite technologies. “We are testing different technologies and we are seeking to make them effective for on-board PV generation for all kinds of electric vehicles, including buses and trucks,” she further explained.

Benefits

The 10,000 km range, however, is still difficult to reach for most electric cars that are currently on the market due to their current vehicle energy efficiency. “But electric car models are improving dramatically,” Newman stated. “The Tesla Model 3, for example, is much more efficient than the previous versions.”

According to Newman's estimations, the benefits of vehicle-integrated PV are proportional to the solar radiation levels of a given area, its demand for electric vehicles, and its power prices. “If we replace the grid electricity with the power generated by the solar panels in a place like the Netherlands, where there is not too much sun, but electricity prices are close €0.20 euro per kWh, we may have as much as between €150 and €200 in direct electricity savings each year,” she emphasized. “If the panels that you put on your car cost approximately €1,000 or €1 per watt, compared to conventional solar, you can consider a three-to-four-year payback time and there is a reasonable benefit here.”

The CO2 savings are estimated at 250 kg per year compared to electric cars relying exclusively on grid electricity. “This is clearly a benefit in terms of the energy transition, but it depends on the location and what kind of grid you have there,” she said. “In a place like France, where most of the grid electricity comes from nuclear power, you can also have zero emissions and, in this case, you don’t have much of a C02 benefit there.”

The estimations also include embedded CO2 in PV panels based on conventional module manufacturing methods. “We found that in almost all situations the CO2 benefits brought by vehicle-integrated PV are more than with electric vehicles only,” Newman added.

Convenience

Another important factor, which for the Dutch research group is still difficult to quantify, is what it calls the “convenience factor”, which is expressed in terms of solar kilometers and the numbers of times you have to plug your car into the grid. “Through our most detailed model, we assessed a Tesla-like car in the Netherlands, for which average driving reaches around 13,000 kilometers per year,” she stated. “What we found is that you could expect to drive more than 3,000 km on solar and to charge about 25% fewer times when PV panels are installed on the vehicle. And this is annually, but in the summertime, you may even drive for three months without recharging the vehicle a single time.”

In sunny places like Spain and Italy or countries with similar solar radiation levels, the charging time may be reduced by about 40% annually. “And this may be achieved with today’s PV and EV technologies,” Newmann affirmed. “Even in the event of running out of energy, on a sunny day, the panels would have enough power to partially recharge the vehicle and bring it to the closest recharging station, without the need of external help.”

Module integration

When asked if module integration is preferable when made by the car manufacturer or an external body, Newman said that, in the long-term, a better design can be achieved if the solar modules are integrated in the car factory. “The most practical and the most cost-effective solution is the PV system integration within the automotive industry, by the car OEM which is responsible for the car roof or parts of the bodywork,” she said. “After-market solutions, however, may currently be a better way to prove and popularize vehicle-integrated PV in a faster way.” Currently, all the vehicle-integrated PV products that are available on the market are done by car manufacturers.

As for the after-market solution, the integration of PV into the vehicle system will be slightly different on each vehicle. Therefore, the system integration will need to be improved or adapted for different vehicles for optimal performance.

For the integration of the panels in the car’s body component, the TNO scientists want to use modules that are as similar as possible to conventional products used in the solar industry. In this way, they can take advantage of a large-scale supply chain, which provides improvements and efficiencies and costs. “We can afford higher costs than conventional PV, but if we stay close to what the PV industry is doing in terms of manufacturing, we can translate that better value for the solar mobility industry,” Newmann emphasized.

Crystalline silicon

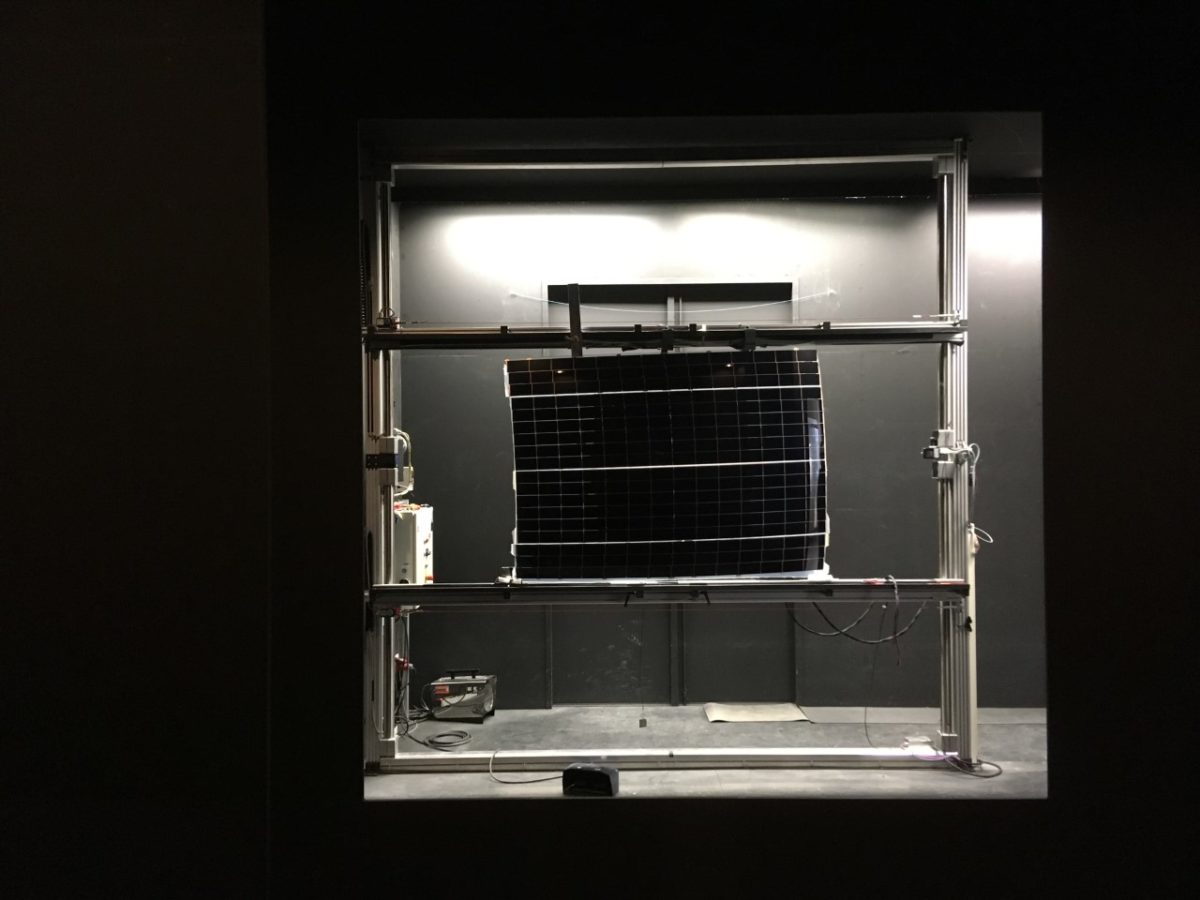

The prevailing PV technology in this market segment remains crystalline silicon PV, as it provides the largest yield. “At this time, we need more energy production density than CIGS can typically provide,” Newman specified. “We are working on CIGS in terms of integration because it has obvious advantages for being lightweight and flexible.”

Crystalline silicon, however, has a much better supply chain from a cost perspective, she notes. “It is possible to curve crystalline silicon panels to the shapes that are needed. Most of the areas of the vehicle are flat enough for crystalline silicon and, for this reason, we consider it the most promising technology for the near future.”

Crystalline solar cells are also easier to connect on the roof, at least with the current state-of-the-art technologies. Crystalline silicon also reacts better to dynamic shading events, as shading can cross a vehicle many different times in different ways and in a very unpredictable manner. “In the future, we can hopefully come up with a solution for thin films that can perform better during these events, eventually adding perovskite or CIGS layers,” Newmann explained.

Safety

The Dutch research team is also working on reliability and safety issues. Crash and splintering tests are performed to understand what happens in the case of an accident, in which the solar panels on the roof or other surfaces of a car may also be broken.

“For example, the voltages from one corner of the roof to the other corner which people would not be able to touch normally, would not be an issue,” Newmann said. “In an accident, however, these pieces of the roof could be much closer together and then potentially endanger rescue workers and the risk of an electroshock cannot be excluded.” The program is intended to ensure that these panels are at the safety levels of a consumer product.

Another important factor is considering what could happen if a car with solar panels on the front side hit a pedestrian, Newmann added. “We have to see how the glass shatters in the event of a collision with a person’s head, for example. We have to see in which way this impact injures the head of a pedestrian compared to a car without panels and we have to be sure that the solar panels will not increase any risk .”

It is very important to avoid these kinds of issues arising in the early stages of this market segment, she stressed. “Even if the technology has clear benefits, we have to make sure it is introduced in a safe way.”

Market size

There are no major hurdles for introducing 21%-efficient panels on the body of an electric car within the next five years and have tens of thousands of cars produced, from a technology perspective. Many people may decide to buy an electric car with integrated PV because of the convenience factor. “By 2030, I could imagine that EVs with solar panels may represent 10% of the EV market,” Newman forecast. “It will be a pretty big market and this percentage is not even that extreme in my mind, if you consider that the payback time is between three and four years.”

Looking forward, Newman said that it would probably be difficult to see electric cars powered exclusively by solar panels. “It will be difficult to get rid of a cable completely,” she concluded. “But there is a good chance that, if you live in a sunny place, you can drive for weeks during summertime without the need for recharging.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

6 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.