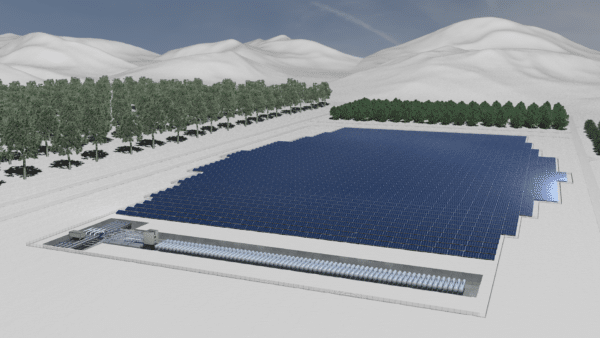

Augwind, an underground compressed-air storage specialist, was one of the biggest winners in Israel's latest solar+storage tender, which was finalized in early January. The Israeli company secured 166 MWh of storage capacity across five solar projects in the procurement exercise, which saw the authorities assign 608.95 MW of PV capacity to seven developers across 33 projects.

“We secured 120 MWh and 20 MWh in two fixed 23-year PPA projects submitted by Israeli developer Solegreen and a further 20 MWh for a solar plant planned by French energy company EDF,” Augwind CEO Or Yogev told pv magazine. “Furthermore, we secured 1 MWh and 5 MWh with Israeli companies Yahel and Meyram for behind-the-meter applications in industrial parks.”

Image: Augwind

Augwind will build the projects at a fixed tariff of ILS 0.1745 ($0.0544)/kWh, which will ensure their bankability, while providing better investment returns than behind-the-meter projects relying on lithium-ion storage, Yogev claimed. The company's energy storage tech will generate recurring revenues based on two factors.

“First, offsetting off-peak to peak electricity consumption and, secondly, providing all compressed air requirements using 40% more efficient compression cycle,” Yogev explained.

Compressed air

Yogev said that Augwind's solution is cost-effective for power generators with minimum capacities of 1 MW and four hours of storage. It relies on a stationary storage technique that has been in use for years, with a focus on the use of compressed air to optimize the efficiency of industrial facilities.

“Compressed air can be used to generate power,” he said. “It can also be utilized for the common compressed air needs of any manufacturing facility.”

Augwind has developed a patented air-compression method that purportedly produces compressed air at a much higher efficiency level than in standard compressors.

“This core technology is already implemented with the AirSmart system for industrial energy efficiency applications in over 60 installations in Israel and abroad, including PepsiCo in California,” Yogev said.

It has already used its AirBattery energy storage systems for short-term and seasonal electricity storage applications.

“I would define our core technology as an enabler for both high capacity energy storage and industrial compressed air services,” Yogev said. “Or a hybrid system that is ideal for each factory in the world that needs a clean, cheap renewable-based power supply and a more efficient compressed air process.”

Polymer tanks

The main components in Augwind's storage system are AirX inflatable polymer tanks. The company outsources production of this patented technology to third parties. The tanks are covered by steel frames, which create a sort of cage around them.

Image: Augwind

“These structures are intended at supporting the weight of the ground when the polymer tanks are empty,” Yogev said. “So these tanks are designed not only to sustain internal pressure but also external pressure.”

The caged inflatable balloons are placed in holes at a depth of 4 meters. The company then pours a cement-based material around the tanks to fill all the gaps created by the inflatable balloons.

Once the installation of the tanks has been completed, they are no longer visible, but are accessible for maintenance purposes via manhole covers. Once everything solidifies, the polymer tanks adhere to the walls of their respective cages. These cavities each contain 60-cubic-meter polymer tanks that can store compressed air at a pressure of 40 bar.

Augwind's system is based on two compression tanks that are placed in the ground close to each other, in addition to a series of storage tanks. The tanks are each 13 meters in length, with a width of 2.5 meters. The power produced by utility-scale PV arrays or wind farms can be used to power standard water pumps, which inject water into the compression tanks. The tanks are sealed, so the air they contain starts to be compressed up to the top, and then shifts to the storage tanks. With on-demand energy, the compressed air is released from the storage tanks to drive a powerful water turbine, which is used to generate electricity.

Yogev explained that compressing air at 40 bar with a standard mechanical piston would generate temperatures of around 800 C, which would make the operation of the battery more complex and less efficient.

“Instead, with our technology, the air is compressed with water and the heat produced by the compression is dissipated into the water itself,” he explained. “We created a process in which we compress the air without generating any heat and this isothermal process has a 100% efficiency, as there is no loss of energy consumed by the pump.”

Yogev claimed that Augwind is the first company to achieve such isothermal conditions in compressed air storage technologies.

He said that heat dissipation is also possible due to the big polymer tanks that are used to store compressed air, as well as the special concrete mixture used to cover the underground tanks.

“The concrete we use, which is also a company's patented technology, is able to levelize itself inside the hole while pouring into all small cracks and voids,” Yogev explained. “The mixture we use cannot only help the system sustain external and internal pressure but has also thermal properties that enable a very efficient compression cycle.”

Charging cycle

One of the two compression tanks is used for air storage, while the second one is used for the compression cycle. When the first tank is filled with enough water, it is pumped into the second tank. This recirculates water back and forth, so it can be reused for indefinite periods of time, with minimal water consumption.

“The beauty of this system is that it also produces water,” Yogev said, noting the system can pull water from the air. “It is because the air has always some residual moisture inside and when you compress it you also generate some water.”

The compressed air is then stored in nearby storage tanks. Their number can be increased according to the desired storage capacity.

Discharging cycle

Water is used to pump the air in the charging process, as the interaction of water and air generates minimal heat. In the discharging process, the 40 bar of compressed air can produce a water jet that can push the water up to 400 meters in the air, according to Augwind. This water is pumped into a hydro turbine, which are smaller versions of the turbines used in pumped hydro plants, in order to reproduce electricity.

“Compressed air is the energy and water is just the medium,” Yogev said, noting that the system can produce more electricity if more pressure is applied.

“The more the energy will be pressurized in the tank, the cheaper the energy will be that we will produce out of it,” he added.

When it is coupled with PV power production, the entire underground system can be covered by the panels. There is zero impact on the module temperatures, as the minimal heat produced in the isothermal compression process is completely absorbed by the concrete mixture.

Image: Augwind

Pumped hydro

Augwind claims that its technology is safe, with zero risk of explosions.

“The only risk is leakage, and it means some air will be leaked to the ground,” Yogev said, adding that this issue can be easily resolved with quick repairs. “Our solution is similar to groundworks – we don't use any polluting materials, we use air and closed-circled water as raw materials and our carbon footprint is very limited, the system can be installed underground functional areas, this means that you can build your generation facility or a data center for example on top of the subterranean storage tanks.”

The solution is also modular, which means it can be deployed for 10 MWh or 100 MWh systems with the simple addition of more polymer tanks. Yogev said the technology works like common pumped hydro storage, with the only difference being that the systems can be quickly installed almost anywhere, on a bigger or smaller scale, with a relatively small footprint, and at much lower capex levels. “And you don't need a water reservoir,” he added.

Image: Augwind

The company said the storage solution has an efficiency of 80%. It claimed that this compares to an efficiency rate of up to 90% for lithium-ion storage. Despite the lower efficiency levels, the compressed air solution purportedly has a lifecycle of more than 40 years, with minimal degradation over an unlimited number of cycles. This compares to an average lifecycle of 12 years and 4,000 cycles for lithium-ion batteries.

“We have a clear path for cost reductions going forward and that is something that traditional pumped hydro cannot have,” Yogev said.

Augwind also said that its technology is considerably cheaper than conventional compressed air storage solutions, or storage in salt caverns. Yogev claimed that salt storage only makes sense with massive, gigawatt-scale projects.

“Our business model is applicable to wind and solar energy projects ranging in size from a few megawatts to several dozens of megawatts, for which conventional technologies for compressed air storage are not applicable,” he said.

*The article was amended to eliminate inaccurate figures about the system costs.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

What is the capital cost to install a MWh of this storage? The $0.0544/kWh doesn’t tell me how much it costs to install or how many kWh per month or year that rate applies to.

Thanks.