Solar cells manufactured from gallium arsenide (GaAs) and gallium indium phosphide (GaInP) have long yielded some of the highest conversion efficiencies of any technology, even though the high cost of these materials and the techniques to process them has kept progress largely confined to laboratories, save for a few niche applications in drone, satellite and spacecraft technology.

The National Renewable Energy Laboratory (NREL) in the United States has long been a leader in this area. Its latest collaboration with another renowned solar PV research institute, the University of New South Wales, has set a new efficiency record for a tandem solar cell and revealed a promising new approach to designing solar cells.

The record-setting cell is comprised of a top layer of indium gallium phosphide (InGaP) and a bottom cell of GaAs. The cell achieved 32.9% efficiency thanks to several new innovations in cell design. “Key to the cell’s design is a series of more than 150 ultrathin layers of alternating semiconductors that create quantum wells in the cell’s bottom absorber, allowing it to capture energy from a key range of the solar spectrum,” the NREL researchers explain.

This alternating structure enabled the group to take advantage of quantum wells, structures which help to trap charges in the material, and to convert a wider part of the light spectrum into electricity. The cell is described in the paper High Efficiency Inverted GaAs and GaInP/GaAs Solar Cells With Strain-Balanced GaInAs/GaAsP Quantum Wells, published in Advanced Energy Materials

Strain balancing approach

The group notes that its work here represents the first significant achievement with this approach, and overcoming challenges in the complexity of growing so many ultrathin layers could unlock further efficiency records in future.

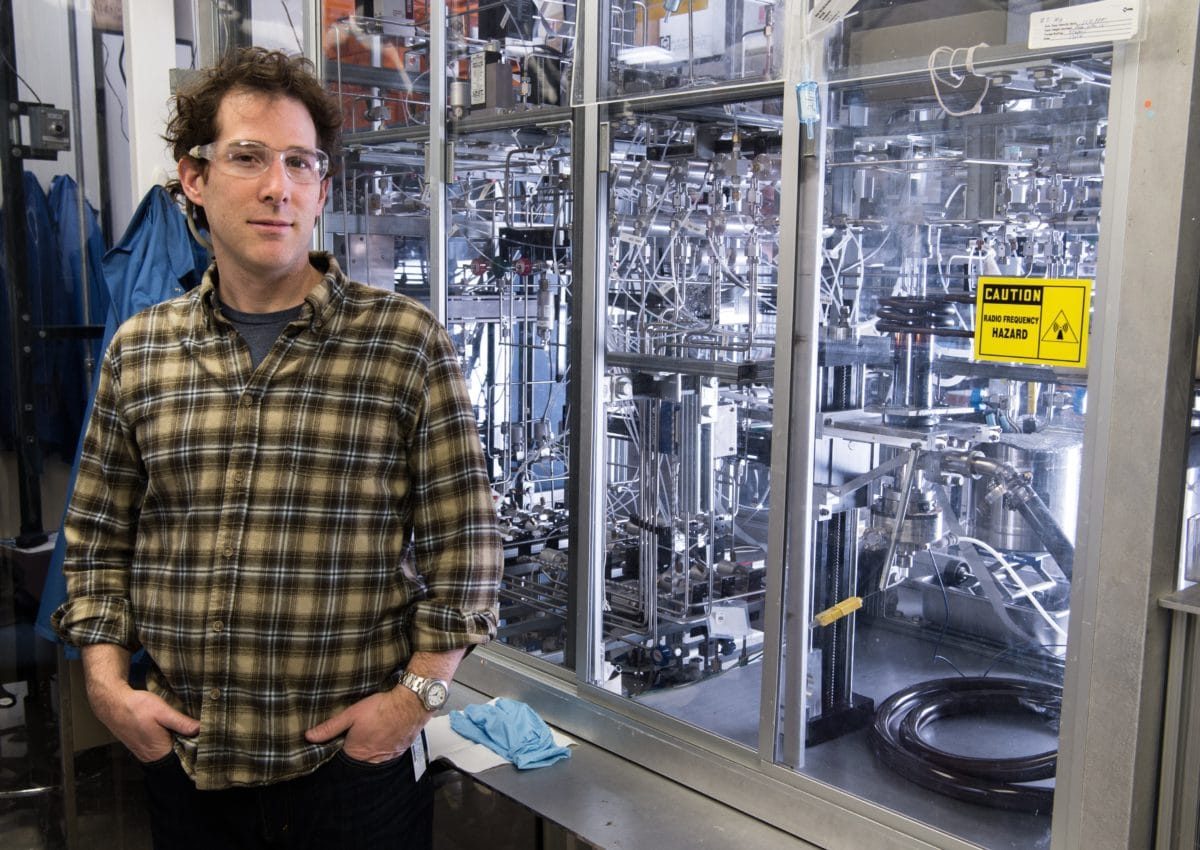

The materials used and the intricacy of the processes to create the cell, however, mean that cost effective production is likely to remain a challenge for the foreseeable future. “This work will lead to higher-efficiency solar cells for one-sun applications, which could be a significant driver of the widespread adoption of these cells,” said Myles Steiner, a senior scientist on the NREL team. “Now, a key challenge ahead is to learn how to manufacture these cells in a cost-competitive manner.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.