Among the many directions in which battery technology could move over the coming years, solid-state designs, which do away entirely with liquid/gel electrolytes and allow for the use of a lithium metal anode, are among the most promising.

Similar to many emerging technologies, there is still plenty of disagreement over what challenges remain and when we might begin to see a significant market impact. Among the more bullish developers is U.S. based company Solid Power, which has been working on solid-state batteries and large-scale processes for their production for the past several years.

And the company this week announced that it has begun pilot production of 22-layer, all-solid-state battery cells at its pilot line in Colorado. Solid Power reports that these cells achieve an energy density of 330 watt-hours per kilogram, well beyond what has been achieved with today’s commercial lithium-ion technology.

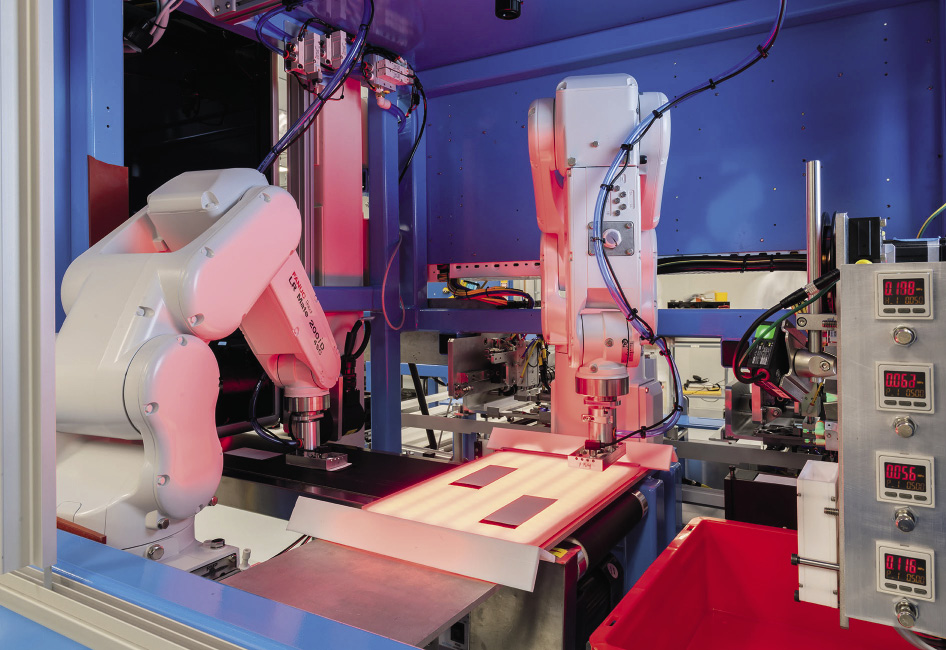

“Solid Power has shown that our all solid-state cell design can be produced using scalable processes on industry standard lithium-ion equipment, and early multi-layer prototype cells using a highly conservative cell design have already exceeded the energy performance of today’s lithium-ion cells,” said CEO and co-founder Doug Campbell. “Proof of successful scale-up is key to realizing the potential of any next-generation battery technology, which is why lithium-ion roll-to-roll compatibility has been our mission since day one.”

The next phase will be validating the processes used on the pilot production line for further scale up. Solid Power has working partnerships with Ford and BMW, as well as other major battery players, and says its expects to be able to begin the formal process of qualifying its technology for use in commercial electric vehicles by early 2022.

Encouraging results

Solid Power also reports that it has sent out prototypes of its new batteries for third party testing, while its own results show stable operation for 250 cycles at room temperature and capability for continuous discharge at rates beyond what would typically be needed to power an accelerating electric vehicle.

A little further from the production line, the company says it can also produce cells that can reach 50% charge in under 15 minutes, and stable operation down to minus 10 degrees Celsius. “Solid Power is proving that an all solid-state platform can excel in environments ranging from below freezing to 70°C with an inherently safer chemistry that is free of flammable liquids or gels,” adds Josh Buettner-Garrett, Solid Power’s chief technology officer. “Solid Power has now demonstrated feasibility of large format cells produced on the same equipment used for conventional lithium-ion, and we are excited to push the performance further as we move toward automotive qualification.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I hope they’re sandbagging on that “250 cycles” metric. If not, they’ve got a long way to go before they’re feasible to use in EV’s. Even today’s Li-Ion cells are more like 1,200 cycles @80% capacity.