While research into perovskite solar cells has made impressive progress in recent years, many of the most notable achievements are recorded on devices measuring less than one square centimeter, and using processes that aren’t practical for the production of large-scale commercial devices.

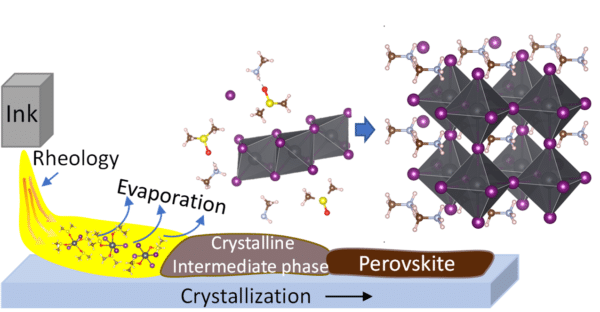

Translating these lab achievements into mass production is another area of research that leaves plenty of questions open. Many different processes are suggested as suitable to this, with slot-die coating and inkjet printing both prominent in literature. These, and many of the other options, involve creating an ‘ink’ substance containing solvents and precursor materials, which is deposited onto a substrate and left to evaporate, forming the perovskite crystalline structure.

Understanding how the makeup of the ink will affect the evaporation process and the characteristics of the crystalline film will be vital in bringing perovskite solar cell production to scale. And while earlier research has made big steps in establishing the best precursor materials for the perovskite itself, research into solvent mixtures and ink formations for large-scale production is at a much earlier stage.

This is the focus of new research from scientists at the Helmholtz Zentrum Berlin (HZB). A group examined the crystallization process, aiming to define the most important characteristics of the inks, that will decide the performance of the perovskite after evaporation and crystallization. “The complex role of solvents and co-solvents in hybrid perovskite precursor inks on intermediate phase structure and film formation kinetics is not yet well understood,” state the researchers. “…an understanding of the interplay between coordination strength of a solvent and evaporation rates of precursor solutions enables prediction of the predominant hybrid perovskites intermediate solvate phases and the kinetics of their formation from mixed solvents.”

Their work is described in full in the paper Hybrid perovskite crystallization from binary solvent mixtures: interplay of evaporation rate and binding strength of solvents, published in Materials Advances. For the solvent, rheological properties, evaporation rate and formation of intermediate phases are identified as the most important factors to control.

Image: HZB

“In mixtures of solvents, evaporation is dominated by the most volatile component that evaporates the fastest This changes the ratio of solvents that are present upon crystallization,” explains Oleksandra Shargaieva, the paper’s lead author. “the formation mechanism critically depends both on the solvents evaporation rate and binding strength to the lead-halide.”

With the insights gained from this research, Shargaieva says that the group should be able to predict how a crystalline thin-film will form, based on the combination of materials in the ink. And this in turn should help to design suitable inks for a range of different manufacturing processes being trialed for perovskite cell production. “There is still a lack of systematic knowledge when scaling up from laboratory scale to industrial area sizes, says Eva Unger, leader of the young investigator group hybrid materials formation and scaling at HZB. “With these results we pave the way for further ink design to enable industrial-scale manufacturing or perovskite thin films of high quality.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.