Prof. Henry Snaith’s photovoltaics research group at the University of Oxford, wasn’t set up as an academic incubator, but for the startup Swift Solar, it played that role.

“We can trace everything back to myself, Tomas, Max and Sam working in the same research group at Oxford,” said Giles Eperon, co-founder of Swift Solar. At that time, huge advances and new discoveries in perovskite technology were made almost weekly, and Swift Solar’s founding members were all working on the technology.

After leaving Oxford, the founders kept working on different aspects of perovskite technology at MIT, Stanford and the University of Washington. “I was working on ways to make good low wavelength absorbing perovskites, and Tomas and Kevin had been working on how to really stabilize perovskite devices to the point that we could grow two on top of each other,” Eperon said.

After they discovering that their research was naturally complimentary, the team regrouped for a few weeks to conduct intensive research. “[We] managed to make world-record perovskite tandems,” Eperon said, noting that the record was for the percentage of power from photons turned into useful electricity.

From there, the idea to form a company that could commercialize their technology was born.

Swift Solar was officially founded three years ago with research groups split between San Francisco and National Renewable Energy Laboratory’s (NREL) Golden, Colorado-based research lab.

Highly efficient

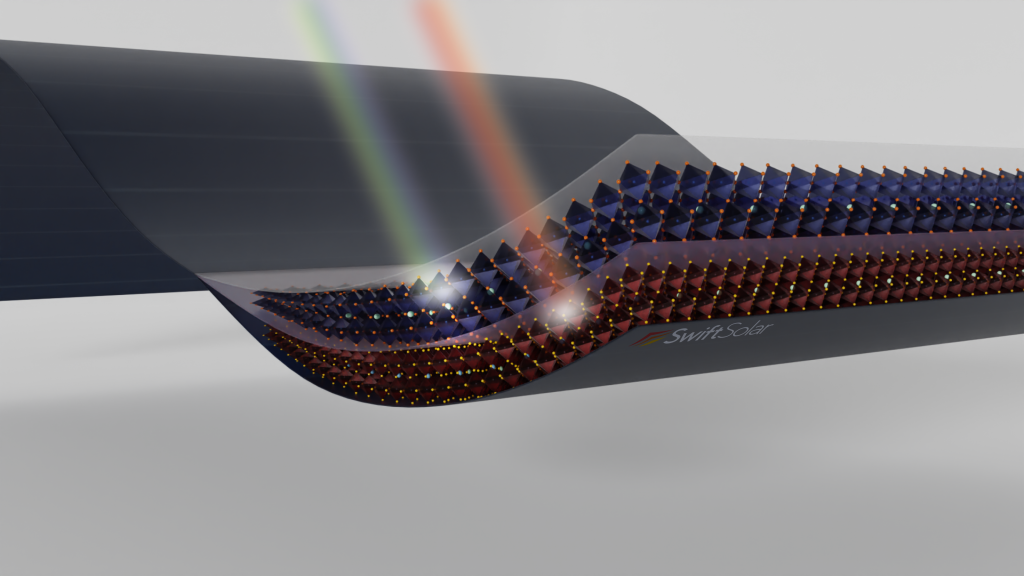

Perovskite solar cells are a type of thin-film solar cell that are highly efficient at harnessing sunlight to generate electricity. Earlier this year, Martin Keller, director of NREL, said that perovskites have the potential to become a game-changer for solar and many other fields.

Silicon is the cheapest technology right now, but, once scaled up, Swift Solar expects its panels to produce more power per dollar than silicon.

According to Eperon, silicon panels are inexpensive and good for helping to de-carbonize the world, but they are not good enough.

“[Silicon panels] are pretty much reaching their maximum possible efficiency, and prices for installations are becoming limited by non-module costs … Also, building new silicon production facilities is very expensive, due to the high-temperature processing they use,” he said. “The bottom line is we have the potential to make panels that are more powerful, cheaper and can be mass-produced at very high rates – all of which is needed to rapidly de-carbonize the world’s energy production.”

Currently, several other companies are targeting single-junction perovskite panels and perovskite-silicon tandems, but Swift Solar is the only one developing all-perovskite tandems.

“Using two layers like this provides higher power conversion efficiencies – a theoretical limit of about 47% vs 33% for a single layer – and because both layers are perovskite, which is an earth-abundant and cheap material, the costs can stay very low. We are also able to make these layers on thin, flexible substrates and foils,” Eperon said.

“We invented the key components enabling the all-perovskite tandem technology… We’ve licensed patents that we filed in our previous institutions – Stanford, MIT and NREL – and have filed several from Swift,” he added.

Multiple factors

Perovskite technology has been around since 2012, and many early investors in solar got burned by the previous generation of thin-film solar – mainly CIGS and CdTe technologies. “[These technologies] promised great things, but they were mostly never able to realize them,” Eperon said.

A number of factors caused most of these first-generation startups to fail, but the main one was that many of the companies active in this space were trying to make utility-scale products. This put them in direct competition with established silicon technology during a decade when the price of silicon dropped dramatically, essentially making the thin-film technologies non-competitive.

“We have learnt a lot from these failed startups, and [we] have tailored our market strategy to avoid initial direct competition with silicon,” Eperon said, adding that a few members of Swift Solar’s advisory board participated in the first generation of startups and have offered guidance based on their experience.

According to Eperon, the key to its technology’s high efficiency is the tandem nature of stacking two perovskite layers on top of each other. “For durability, our team has a lot of expertise in making perovskites more stable, and we’re able to utilize the learnings of the previous thin-film technologies to develop good packaging solutions,” he said.

There aren’t any commercially available perovskite products yet. “Which isn’t surprising as it’s only been around as a technology for about eight years,” Eperon said.

“We are implementing a series of accelerated aging tests that will give us a good idea of how long these panels will last in real operation… It’s hard to say we’ll be able to reach 30-year stability, like silicon does, until our panels have been around for 30 years,” he added. Perovskite technology currently has a shorter lifespan versus silicon, but further research might bring it to a similar or longer lifespan, he noted.

Covid-19 reset

Covid-19 threw Swift Solar a curveball this spring. It shut down research and injected uncertainty into the market, making investors hesitant to commit. “But we were able to focus on doing some important market research,” Eperon said. During this lull, Swift Solar started having deep discussions with early customers, and this helped Swift fine tune its focus.

Because Swift Solar is able to make its stacking tandem layers on thin, flexible substrates and foils, it can use its technology to create flexible, high efficiency and lightweight products, Eperon said. In light of this, the company decided that aerial vehicles – like communication drones that can be used in lieu of satellites – will be an early area of focus, he added.

“They are compatible with small-scale panels…[And] it’s easier to guarantee the lifetime specs,” he said, noting that Swift’s aerial vehicle customers estimate that their drones have to be retired after two to three years because of wear and tear on their wings. “Our technology fills a need. [Aerial vehicles] need a lot of power with as little weight as possible,” he explained.

“Since we’re making lightweight, flexible panels, we have market opportunities that [other companies working on perovskite-silicon tandems] don’t,” Eperon said. “[Our technology] is ideal for applications that wouldn’t be able to use heavier panels,” he added. In time, he expects that the electronic vehicle (EV) and the warehouse solar rooftop markets to offer a lot of opportunities. “Silicon panels are sometimes too heavy for a warehouse roof,” he said. On the EV side, Swift Solar will explore charging applications.

Initially, Swift Solar’s pilot plant, which it plans to launch in California within a couple of years, will focus on developing small-scale panels suited to aerial communication vehicles, solar-powered water pumps and mobile solar-powered microgrids.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.