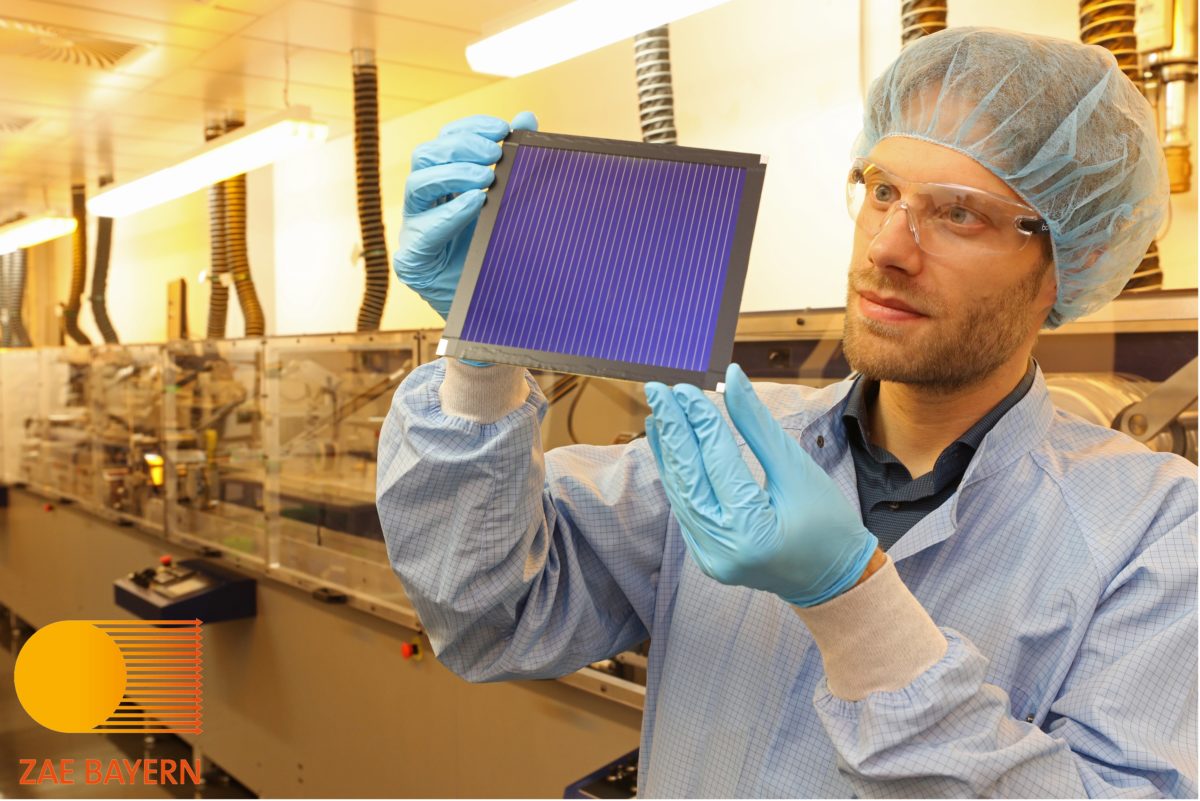

Researchers at German institutions the Bavarian Center for Applied Energy Research, the Friedrich-Alexander University Erlangen-Nürnberg and the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy have developed an organic-solar-cell PV module they say has achieved two conversion efficiency records.

The scientists said their 26.14cm2 module, featuring 12 cells connected in series, achieved a certified efficiency of 12.63%, besting the previous world record of 9.7% set by Toshiba; and a 204cm2, 33-cell version achieved 11.73%, topping the 8.7% efficiency also posted by Toshiba on a device of that scale.

The researchers said the records were obtained using a new module layout and a slower, high-resolution, short-pulse laser structuring process. “Losses due to manufacturing imperfections can be eliminated almost completely by careful design of the manufacturing process,” said the German group, adding the laser structuring enabled a homogeneous coating of all cell layers.

“By minimizing the inactive areas within the total module area that are used for interconnecting the individual solar cells of the module in series, geometric fill factors of over 95% have been achieved,” said the researchers.

Slower, nanosecond-pulse laser patterning was used – rather than femtosecond pulses – to avoid laser ablation of active layer material in the active area. The billionths-of-a-second technique reportedly offers more selectivity and better quality – as well as being cheaper than – pulses made at quadrillionths of a second.

“From our point of view, both records are of great importance because photovoltaic devices can be classified in those different area categories and are done so in the world rankings,” research co-author Andreas Distler told pv magazine. “For example, the Martin Green Table (PiP) lists records for cells below and above 1cm², as well as for modules below and above 200cm². Therefore, we are currently listed in the Martin Green Table with both records. Another important ranking is the NREL [U.S. National Renewable Energy Laboratory] champion module efficiency chart, which requires more-than-200 cm² modules, i.e. we are listed there with the 11.7%.”

Referring to the 12.6% record, Distler said it could also be reached by the larger module but the equipment used by the researchers makes it difficult to maintain a homogeneous film thickness over the surface of bigger devices. “With improved equipment, I am sure the 12.6% PCE [power conversion efficiency] could also be reached on the bigger module area,” he said.

The modules and related manufacturing process are described in the paper Organic photovoltaic modules with new world record efficiencies, published in Progress in Photovoltaics.

Researchers in South Korea have recently suggested spin coating could lead to more efficient large-area organic modules by enabling bulk-heterojunction (BHJ) films for such devices, and would also make such modules more easily replicable.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.