Wafers used in cell production today are typically 180-200 microns thick. Going thinner than this is widely thought to bring about problems with the wafer being too fragile to withstand the stresses it is put through both during production and in the field. And since the cost of polysilicon has fallen continually in recent years, manufacturers lack a strong incentive to cut down on consumption.

Among researchers though, there is still plenty of interest in ‘ultrathin’ cells at thicknesses of 50 microns or less. As well as saving on polysilicon costs, these could lead to much lighter and more flexible cells suitable for applications beyond conventional PV modules. And scientists also theorize that working with ultrathin wafers could open doors to higher efficiency achievements.

Scientists led by the Korea Institute of Science and Technology (KIST) claim to have found a way to increase the mechanical flexibility of cells 50 microns thick, by etching a light-trapping nanostructure onto their surface.

Light trapping

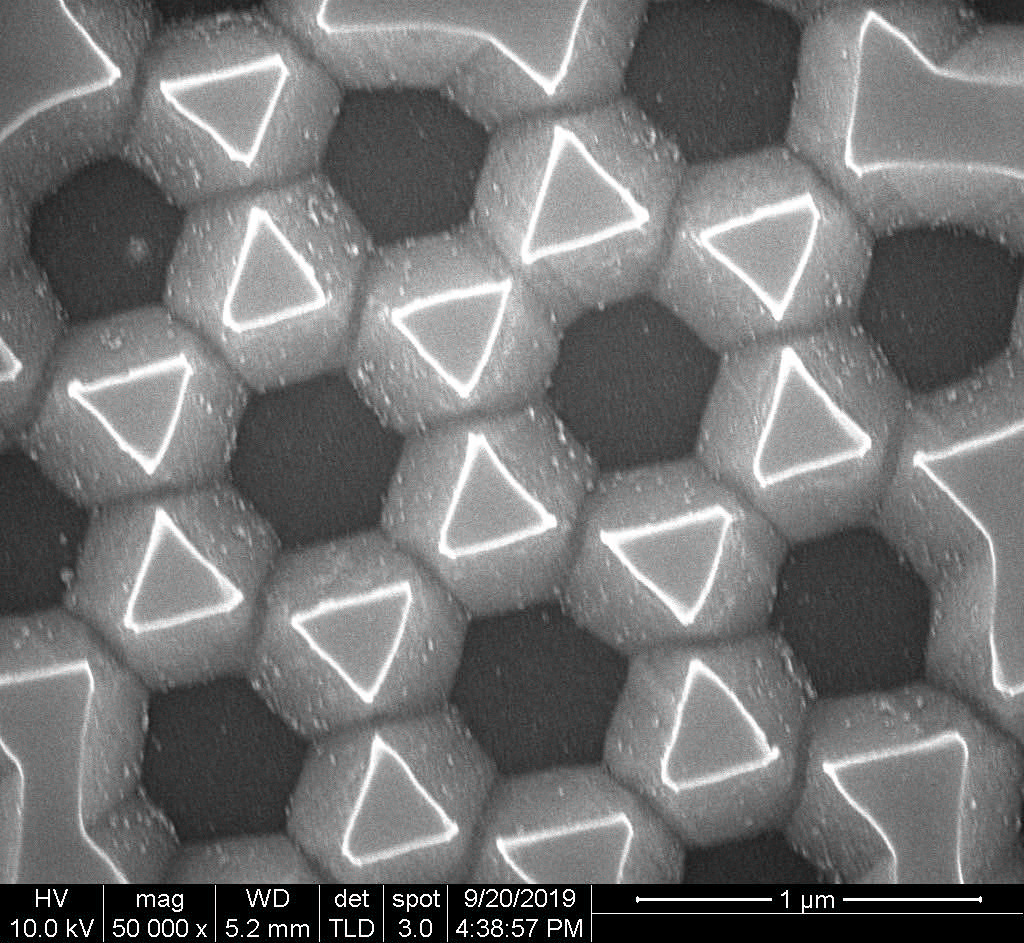

Cells in production are typically etched with a pyramid-like structure, which ‘traps’ more light, preventing it from being reflected away from the cell. The group at KIST investigated ways to make this pyramid structure even smaller, and found that they could achieve results comparable to conventional processes, whilst significantly improving on the mechanical flexibility of the wafer.

The work is described in the paper Fabrication of quasi-hexagonal Si nanostructures and its application for flexible crystalline ultrathin Si solar cells, published in Solar Energy. The group used a combined process of nanosphere lithography and wet etching to fabricate cells with a quasi-hexagonal nanostructure on their surface. Cells etched with the nanostructure had a critical bending radius 46% lower than those with conventional pyramid etching, and showed efficiencies around 1% lower.

“The production of thin wafer-based solar cells is very challenging due to the fragility of the thin wafers. Thin wafers with surface cracks or textures are more prone to breakage because the surface microstructures act as stress concentration sites.” KIST senior researcher Inho Kim told pv magazine. “We do not have data about breakage yield of thin wafers in production. But we can say the breakage yield of the thin wafers textured with the nanostructures would be greatly reduced, compared with the conventionally textured (micro-pyramids) wafers.”

With further optimizations to its process, the group expects that its approach to nanostructuring could also yield better results in terms of light trapping and cell performance, on top of the demonstrated benefits to mechanical flexibility.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.