The solar industry’s biggest manufacturers are continuing with ambitious expansion plans, indicating that they see little reason to worry regarding long term demand for PV modules. And major players continue to invest in PERC production, suggesting the technology will continue to be the mainstream in production for several years yet.

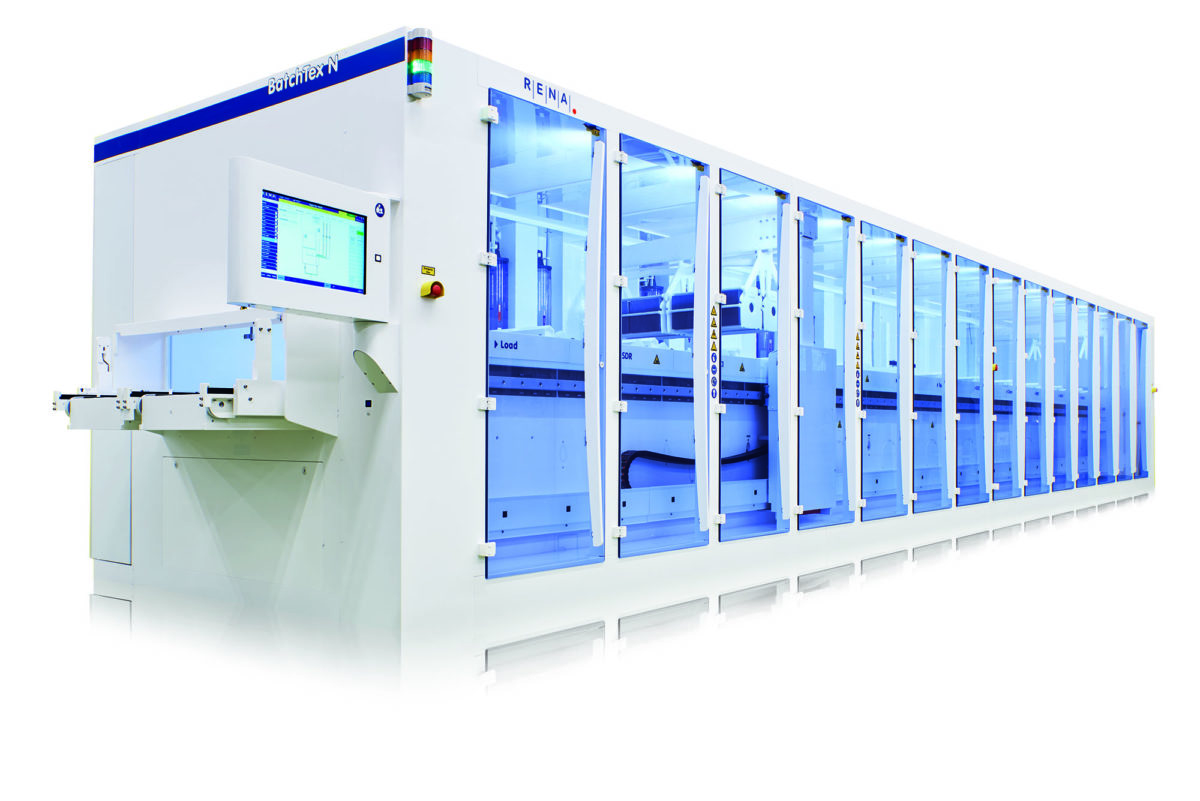

The latest evidence for these trends comes in the form of a 15 GW order worth tens of millions of euro for wafer texturing equipment produced by German supplier RENA Technologies. The order, placed by an unnamed tier-one manufacturer, is for two of RENA’s wet chemical processing platforms – BatchTex XL and InOxside Fusion – both used in the cleaning and preparation of wafer surfaces for cell production processes.

“We are implementing extremely innovative technology which has been developed by our teams in Germany and China in record time,” said RENA CEO Peter Schneidewind. “We are delighted that the innovative strength of RENA and the reliability of our systems are valued by our customer.”

Cost down

Both platforms, according to RENA, will serve to reduce production costs for the customer, with the InOxside Fusion said to use significantly less nitric acid than its competitors' tools. The tools will process wafers up to 210mm – which now appears to an established trend among manufacturers. “The comparatively space-saving solution offers our customer enormous potential savings and sets new standards in wet chemical processing technology,” added RENA’s vice president of Sales Ulrich Jäger. “The trend towards M12 [210mm] wafers continues to grow and thanks to our machines, we are extremely well prepared for it.”

Though many European based PV equipment suppliers have struggled in recent years thanks to competition from suppliers based in Asia, wafer texturing is one of a few areas in the production where a European supplier has successfully maintained market share.

Speaking with pv magazine back in January, Schneidewind noted that it still counts three tier-one manufacturers among its customers, attributing the company’s success to innovative products and a strong presence in China. And the company further notes that after the SNEC exhibition went ahead in Shanghai last month, it has seen significant interest in its solutions from several other cell manufacturers.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Very like informatione .Rena order