Scientists from the RISE Research Institutes of Sweden and the UK's Sheffield Hallam University have conducted a research to investigate how glass technologies for PV modules may be improved in terms of mechanical, chemical and optical properties.

In the paper Towards improved cover glasses for photovoltaic devices, published in Progress in Photovoltaics, the researchers stressed that it is crucial for glass improvement to reduce the concentration of iron oxide species within the glass front sheet, while also providing sufficient absorption of UV photons to protect the ethylene-vinyl acetate (EVA) copolymer encapsulants used for solar module lamination.

The reduction of iron oxide species can be implemented, the researchers said, through the so-called down‐shifting process, which consists of doping the glass with optically active components. This solution has a double positive effect, as the doped glass absorbs harmful UV photons while also re‐emitting some of this absorbed energy as photons of visible light that can be captured and converted by the solar cell, they further explained.

In order to ensure that any benefits for UV protection are not offset by the negative impact on light transmission of the cover glass, the use of glass dopant cations that produce no absorption bands is crucial. “The large majority of first‐row transition metals, when doped into glasses, suffer this limitation,” the scientists stated.

They identified nontoxic bismuth (3+) coupled with gadolinium (3+) as dopants for new glass configurations and testing in lab‐scale PV modules. The two compounds are two cations made of bismuth and gadolinium having both a net electric charge of +3.

The doping with these two compounds reduces the UV transmission while also keeping the glass free from absorption in the visible and near-infrared ranges. “This is augmented by broadband down‐shifting of absorbed UV photons and re‐emission as visible photons available for conversion by the solar cell,” the researchers concluded. “The compound effect of these compositional changes to the cover glass thereby enables both increased efficiency and increased lifetime of PV modules.”

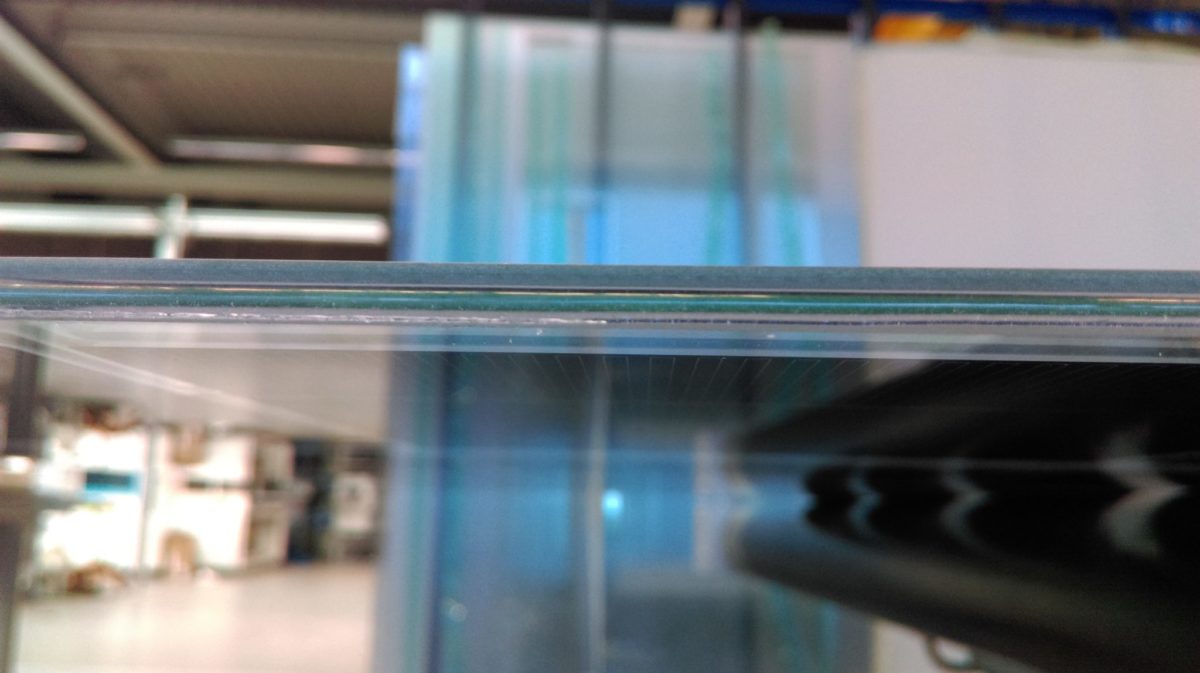

As for the mechanical performance of the PV glass, the research team pointed out the need of manufacturing thinner glasses with enhanced robustness, which would ensure a reduction in panel weight and costs. The glass strength is an extrinsic property that depends to a major extent on the surface of the glass rather than on its bulk, according to the report.

The researchers noted that 3 mm is commonly considered the minimum thickness, and that a 2 mm or thinner toughened glass can also be achieved with an improved process, in which the rollers are replaced by gas flotation systems in the furnace.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.