From pv magazine Germany.

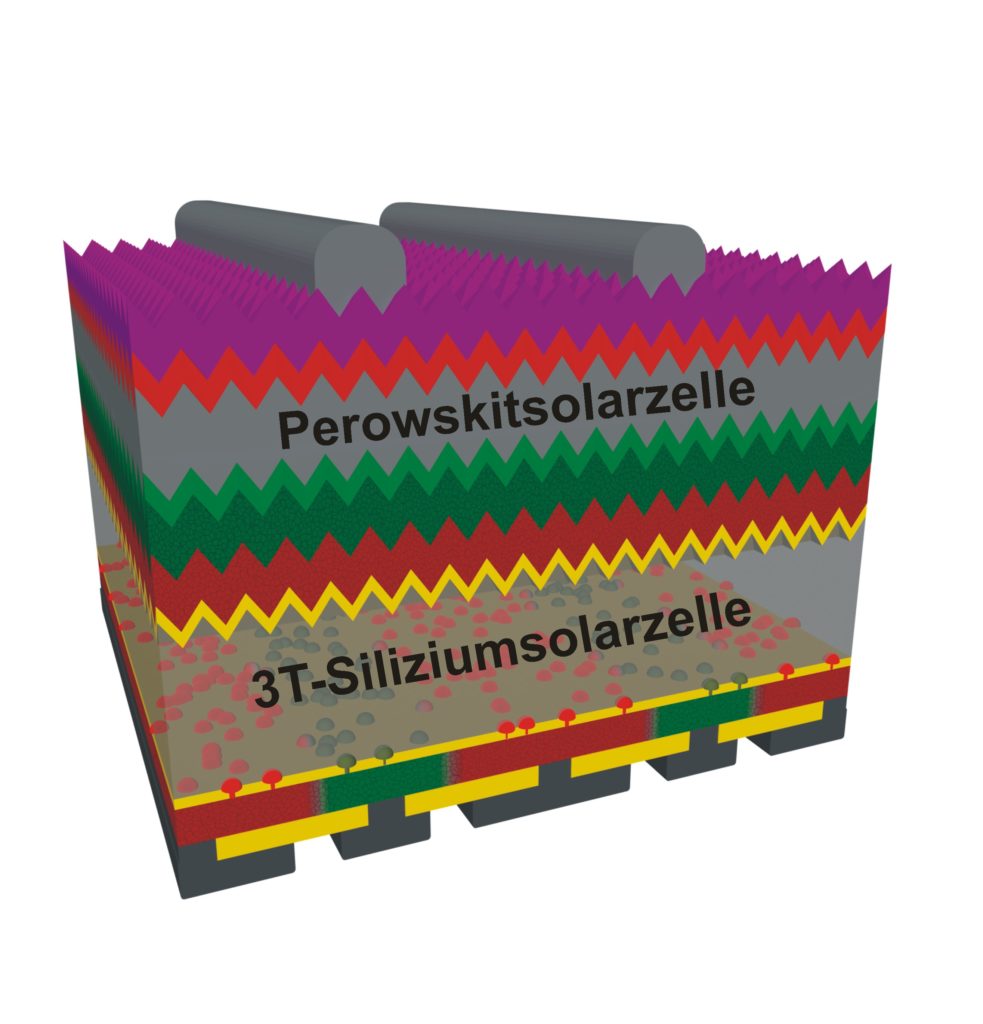

It is called '27plus6′: A new research project bringing together the expertise of leading German and Swiss technology companies and research institutes, with the goal of developing a 33%-efficient perovskite-silicon tandem solar cell suitable for mass production.

The project includes Germany's Institute for Solar Energy Research Hamelin (ISFH), the Karlsruhe Institute of Technology (KIT) and the Institute for Materials and Components in Electronics at the University of Hannover, as well as PV equipment providers Centrotherm, Singulus, Meyer Burger and Von Ardenne.

The consortium said that it aims to achieve the promised conversion efficiency under standard test conditions, and that is also seeking to reach a higher power yield, intended to accelerate industrial implementation.

The scientists explained that the real solar spectrum changes over the course of the day and varies seasonally and with geographical location. And for tandem cells, where the different layers may perform differently depending on the light conditions, adjusting the current for optimal output from both cells in a typical two-terminal configuration can be a difficult task.

Research projects have also investigated four-terminal setups as a way around this problem, but these appear to come with their own set of complications. The “27plus6” project will aim at developing 3-terminal cells, which it says are characterized by greater robustness in relation to changes to the solar spectrum. Combined with innovative new cell interconnection concepts, the consortium is convinced this approach will lead to higher energy yields from the cells.

The ISFH brings its expertise in the development of back-contacted silicon solar cells with passivating contacts to the project, and wants to further develop the deposition of perovskite absorbers on textured surfaces by means of co-evaporation. KIT, meanwhile, contributes its expertise in the field of perovskite cell development, for example, the realization of two-dimensional perovskite crystal structures.

The equipment suppliers will bring their considerable knowledge of mass production processes to the group. Centrotherm in particular states that it wants to further develop its processes for the deposition of passivating contact layers, and optimize these with a view to industrial-scale production.

According to the partners, with the demonstration of a significant increase in energy yield compared to today's silicon solar cells, the photovoltaic electricity production costs in Germany can fall below €0.04/kWh. Thanks to the high efficiency, special photovoltaic applications such as integration in electric vehicles are also conceivable.

*the article was amended on Aug. 24, 2020, to reflect that the researchers aim to reach a 33% efficiency and not, as we previously reported, a 27% efficiency.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Monocrystalline pv cells have reached 26% efficiency in the lab (NREL) , and this continues to rise, very slowly. To compensate for the extra processing, commercial tandem cells need to beat single-junction ones by a significant margin. 27% is simply not ambitious enough to change the game.

Hence the 33% target in the article.

Ah. Now it makes sense. Good luck to them.

Real-world increases to panel efficiency at scale, lower cost per kWh and lifespan of 20+ years are what will drive the shift to tandem cells, it is only a matter of time until we get there. The majority of Si panels that are currently deployed globally are less than 21% efficient. A jump to 33% or even a consistent 25%+ would have a massive impact in a large scale solar plant.