From pv magazine USA

While PV system costs are falling faster than anticipated, there is one module component that isn’t following this trend, and is actually rising in cost significantly: silver. The price of the material has risen by nearly 40% from a year ago, but one company claims it has created a solution that could reduce silver costs by 3%, while also increasing PV module output.

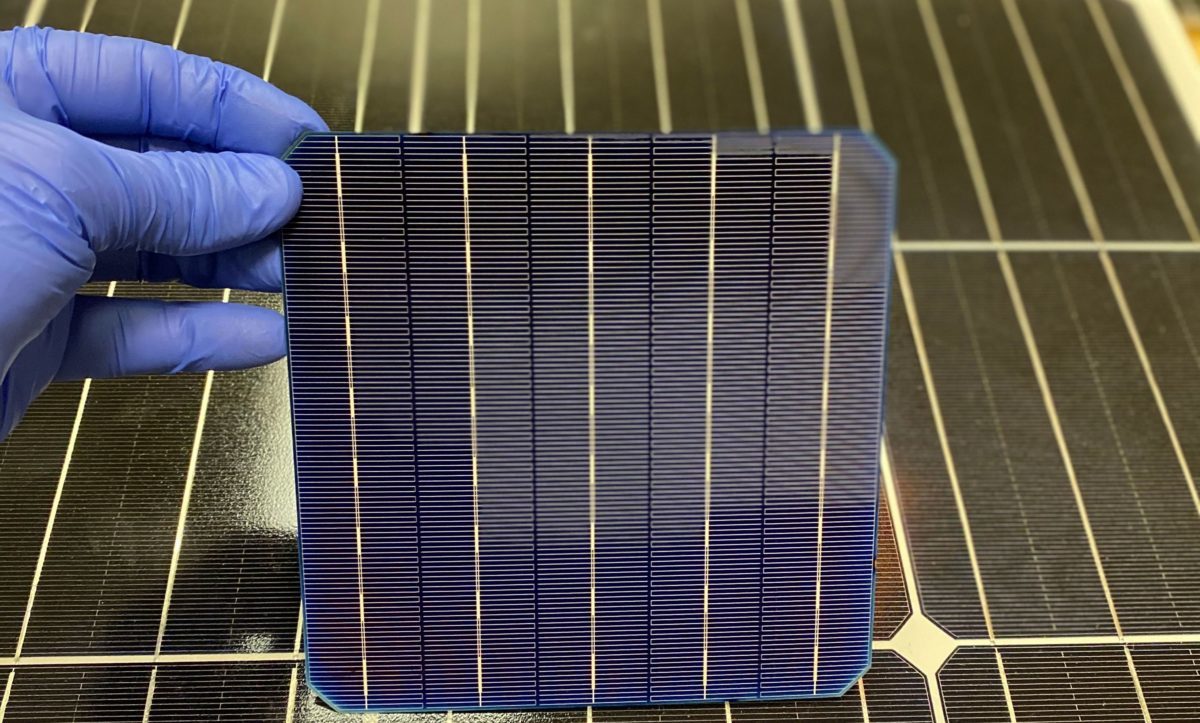

Solar Inventions, the winners of the first American-Made Solar Prize and the creators of Configurable Current Cell (C3) subcell technology – a new PV cell architecture that creates resistively bounded subcells. The idea of creating subcells is nothing new, but Solar Inventions and its chief scientist, Dr. Benjamin Damiani, have been able to develop a way to create these subcells more efficiently, without specialized processing. According to the company’s first white paper, manufacturers are able to utilize C3 with just small changes in metallization print patterns and selective doping. This is achievable via minor print screen modifications and marginal changes to production lines, as C3 configures the subcells in parallel to a cell’s traditional busbars.

The technology works with 95% of all silicon cell architectures, including monocrystalline, polycrystalline, PERC, HJT, and bifacial tech.

Damiani said the reduction of silver costs and higher module power output could bring down module prices by up to $0.01/kWh, which is no small feat. For a 300 MW PERC cell and module manufacturer, according to the white paper, C3 creates nearly $1 million in value through a 3% reduction in silver and an additional 2 watts to 3 watts per 60-cell panel.

“This is an interesting thing,” Damiani told pv magazine. “I have a tendency to want to talk about the cool science and changing the solar cell … but I think what really gets people’s attention is the silver savings.”

These breakthroughs are just the first steps for Solar Inventions. The company plans to release a second-generation technology in the near future, in order to provide greater resistance to microcracks and thermal events, while also reducing the effects of module shading.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

0 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.