Swiss start-up Insolight – founded by three researchers from the École polytechnique fédérale de Lausanne – has closed a CHF5 million (€4.63 million) funding round from several Swiss backers including investment firm Investire and financial services provider Zürcher Kantonalbank. The Swiss Immo Lab real estate innovation company founded by mortgage company Avobis, insurer GVB and lender Hypothekarbank Lenzburg was also among the backers in the latest funding exercise for the concentrating PV (CPV) start-up.

Insolight said it will use the cash, plus €10 million granted by the European Union, to bring its CPV module technology to commercial production.

Originally conceived for rooftop applications, the panel is now being recommended by Insolight as an interesting option for agrivoltaic projects.

Cost

“Our initial goal is to provide the same LCOE [levelized cost of energy] as other agrivoltaics solutions while providing additional agricultural benefits,” Insolight CEO Laurent Coulot told pv magazine. “The cost is projected to be below $0.35/Wp [€0.297] for [a] 100 MWp scenario.”

With Insolight last week revealing module production would be outsourced, Coulot added: “The modules are currently produced in different locations across Europe. We are currently setting up the production of the first 1,000 units for pilot purposes, with industrial partners.”

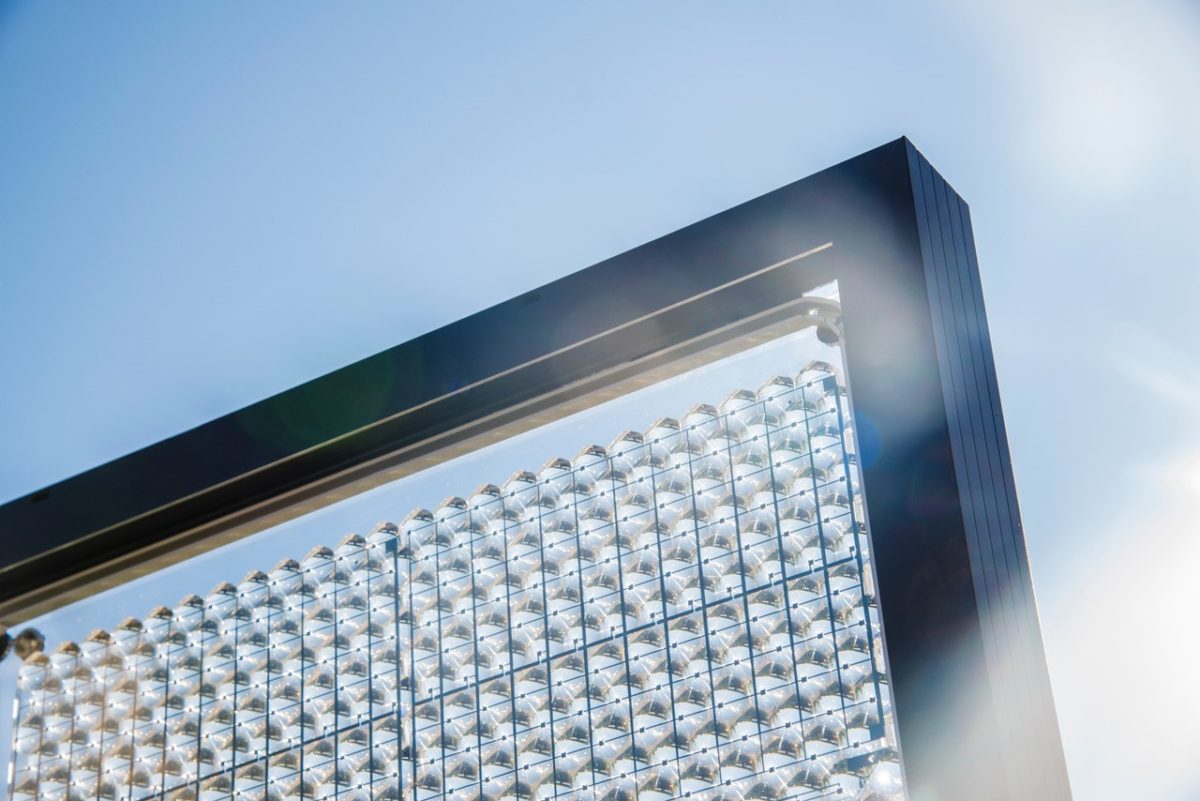

The product spec states the CPV panel has a 30% efficiency and power output of 160 W at standard conditions of 25 degrees Celsius and 1,000 W/m2 irradiance. The product can reportedly operate with maximum system voltage of 500 V and at temperatures ranging from -40 to 85 degrees Celsius. The 1,141x595x50mm module weighs 20 kg and, according to its developer, is as easy to install as conventional solar panels. Its connector is MC4-compatible and its junction box has an IP 67 rating.

Tiny cells

The panel relies on expensive III-V multi-junction solar cells from an undisclosed manufacturer. The cells cover only 0.5% of the panel surface and are covered with protective glass and optical lenses to concentrate and direct sunlight onto them at around 100 times the intensity of standard solar glass. The cells are reportedly able to track the sun through horizontal movement, with the company stating: “Horizontal movements of a few millimeters per day keep the cells aligned with the light beams.”

The company added: “Insolight intends to sell [the] first modules to large solar energy corporates for application in agrivoltaics. There is a unique potential for high efficiency and translucent modules to produce both solar electricity and crops on the land, whether deployed on fields or greenhouses.”

The €10 million grant awarded Insolight by the EU came as part of the bloc’s Hyperion project to sustainably renovate historic areas.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Why would a farmer pay more for CPV? You can get the desired amount of shading with standard silicon PV cells by leaving transparent glass strips. It hot climates, a good part of the return is from crop shading and lower water use, so the PV yield is that much less important.

1.141x.595x1000x.3=204watts, yet they only produce 160watts. That seams more like 23% not 30%? Standard split cells produce 330wartts from a 1.675x.94 Panel (20%) what am I missing here?

Your DNI is not 1000W/m^2 but between 800 and 850W/m^2. This is the usable energy available to the cell via the optics during concentration. The diffuse component has little contribution to the generation and is seen as spillage, unless one uses a hybrid hcpv system. The optical elements in the setup also absorb the photons and can disperse the concentrated beam.

Hence the 160W .

very excellent inventions

Rain channeling and redistribution could present a challenge, including a significant hit on financial return.