Researchers from Spain’s University of Malaga (UMA) claim to have developed two protocols which could be used in industrial solar cell production to identify possible cell failures and separate the devices concerned.

The solar cell pass/fail protocols, which the researchers say could be implemented in an industrial cell tester, act as a measurement tool for ‘dark testing’ – in which cells essentially behave as diodes with a parallel resistance; and for high-temperature reverse bias testing, in which the devices are subjected to high voltage and temperature stress.

One protocol has been defined for solar cells 125mm long and with a 150mm diameter and the second concerns 156mm long cells with a 195mm diameter.

The protocols are said to offer the option of separating out cells which present high hot-spot risk, show very high current leakage and demonstrate intermediate behavior. In the case of hot-spot-based separation, the researchers said, rejected cells can be laser re-processed and, if that step shows improvement, used in PV modules for off-grid projects.

No shunt resistance

“Both protocols are based on voltage and current measurements without the use of … shunt resistance (Rsh), which cannot be provided by all industrial tools,” said the researchers. Research co-author Maricruz López Escalantes told pv magazine that sort of equipment is “not able to calculate … resistance [in line with] standards.”

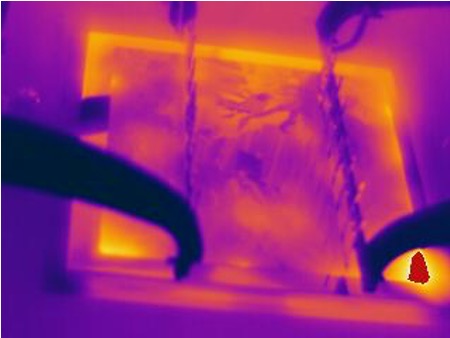

The sorting technique relies on a manual solar simulator, infrared camera and a tool designed to measure isolation. The team took measurements on 26,775 units of the larger cell size and 58,139 smaller devices under dark and reverse conditions in an industrial solar simulator.

The test resulted in around 0.49% of the cells being rejected due to hot-spot risk and 0.28% because of current leakage.

The UMA group manufactured two commercial PV modules with the cells analyzed and sent them to Germany’s TÜV Rheinland Energie und Umwelt Solar Energy Laboratory for testing. “This laboratory performed the hot-spot endurance test according to the IEC61215 ed.3 normative,” the researchers stated. “Finally, the laboratory reports indicate that both PV modules [overcame] the hot-spot aging test.”

The protocols are presented in the paper Shunt resistance criterion: Design and implementation for industrial silicon solar cell production, published in Solar Energy and on the ScienceDirect website.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.