From pv magazine Germany

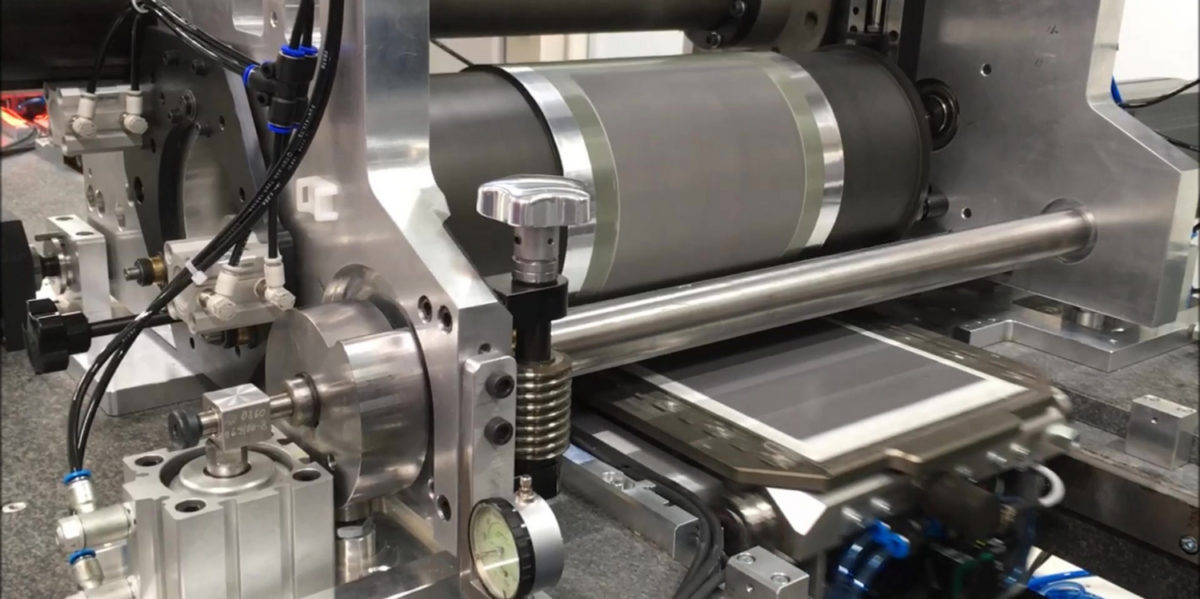

Germany’s Fraunhofer ISE and ASYS Automatisierungssysteme GmbH have evaluated and developed rotation processes for the production of silicon solar cells. The so-called “Rock Star” research project has now been completed with the construction of new demonstrator equipment for solar cell metallization.

The machine is able to transport the cells to be coated through autonomous “shuttles,” with high speed and precision provided by Swiss engineering group Gallus Ferd Rüesch AG.

Depending on the requirements, a rotary screen printing unit and a flexographic printing unit can be activated. Additional printing and coating processes – such as multi-nozzle dispensing and intaglio – can also be integrated, thanks to the equipment’s modular design, Fraunhofer ISE said.

The transport system is able to convey the cells at a speed of up to 600 millimeters per second and can print them with high precision, according to the research institute. If this is compared with the state-of-the-art metallization of solar cells, it corresponds to a theoretical increase in throughput of 100% per track.

“The newly developed technology thus precisely meets the needs of industry for innovative technologies to significantly increase productivity,” explained Florian Clement, head of production technology in the structuring and metallization department at Fraunhofer ISE.

The project shows that it is possible to successfully implement the front and back metallization of highly efficient PERC solar cells using rotary screen printing and flexographic printing, the institute said.

“PERC solar cells with rotary screen printing metallization achieved comparable quality and electrical performance compared to reference cells metallized conventionally in flatbed screen printing, but enable significant cost savings due to the significantly increased throughputs,” said Andreas Lorenz, a scientist at Fraunhofer ISE. “We were also able to produce the first functioning demonstrator modules from solar cells with rotary printing metallization with SmartWire wire connection. We therefore see great potential of this technology for a wide variety of applications, from solar cells to high-throughput coating of functional structures for sensors, smart cards or fuel cells.”

The “Rock Star” project was funded by the German Federal Ministry of Education and Research (BMBF) as part of its “R&D for photovoltaics” funding program. Gallus Ferd Rüesch AG, meanwhile, participated in the project by drawing on its experience as a manufacturer of high-precision rotary printing units and industrially manufactured screen printing plates.

ContiTech Elastomer Coatings GmbH developed micrometer-precise, laser-engraved printing plates. The project was scientifically and technologically supported by Fraunhofer ISE and the Institute for Printing Processes and Printing Machines (IDD) at the Technical University of Darmstadt. The associated partners in the project were Hanwha Q Cells GmbH and Kurt Zecher GmbH.

*the article was updated on Sep. 23, 2020, to reflect that ASYS Automatisierungssysteme GmbH has partnered with Fraunhofer ISE in developing the new equipment for solar cell metallization.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Thank you so much for such an informative article.