From pv magazine 06/2020

Estimating the impact of product piracy in the solar industry is not easy to do. Since the price of a PV module is typically based on its measured output, it may appear that there is no immediate advantage for a ‘pirate’ producer in fraudulently slapping the logo of a more reputable manufacturer onto its own inferior products.

German company Viamon, which provides security services to the PV industry, says that it sees on average one to two cases per year involving counterfeit modules. China-based Quality Assurance provider Sinovoltaics, meanwhile, states that its experience related to counterfeiting is more along the lines of falsified power ratings or quality certifications, and even electroluminescence images being edited to hide cell cracking and other defects.

Several PV module manufacturers, however, have confirmed to pv magazine that they do see fake versions of their products available for purchase in various locations, and that they see solutions to prevent this as a worthwhile investment – even in times where profit margins in module production are stretched thin. “Unfortunately, it is almost impossible to determine an exact number of copycats, but year by year this problem is increasing, and we think that the dark figure is even higher,” explains Waldemar Hartmann, sales director at German module producer AE Solar. “We see it quite frequently by ourselves, and our partners see it around the world.”

When counterfeit modules are detected, AE Solar says it works both with the customer who purchased them and with legal advisers to track down the producer and prevent further counterfeiting. But it notes that with the network of intermediaries between production lines and end customers, it can be difficult to establish who makes such modules.

Norway-headquartered manufacturer REC Group also states that it occasionally sees counterfeits of its modules being sold via online platforms. “Although these are only a few small cases per year, we take these seriously,” says Cemil Seber, vice president of product management at REC Group.

Hartmann goes on to explain that fake branded AE Solar modules are frequently found for sale on online e-commerce platforms such as Alibaba. They also have cases where an end customer has contacted them to complain of a product’s poor performance, only to find that what they purchased was not in fact produced or certified by AE Solar at all. But one case in particular, says Hartmann, led the company to take further action. “A huge manufacturer placed an OEM order with us, saying due to high demand they did not have the capacity to produce their client’s full order,” he explains. “Once we finished the order, and started to unpack the stickers for the panels, we saw that it was AE Solar’s old logo – we already had an upgraded new design. So it appeared that we had made copies of our own brand for another factory.”

Multiple solutions

AE Solar is now introducing an NFC chip for all of its modules, which allows the company to track its panels. The chips also allow customers to reliably authenticate products before buying, simply by scanning them with a smartphone. The chips link with an app that can identify the module with a unique web link, while also allowing customers to directly communicate with the AE Solar team. The chips are laminated under the module glass, so they are difficult to remove without severely damaging the modules themselves. Hartmann notes that while the chips and accompanying mobile app took some years and significant investment to manufacture, AE Solar has not increased its prices as a result of integrating them.

REC Group uses an app-based solution to assist its certified solar installers, which also serves to help prevent counterfeiting, relying on module serial numbers rather than a chip. This is likely less secure, however, REC states that the app allows it to immediately identify any fake serial numbers. Installers are encouraged to use the app to register all installations with REC Group modules, and the company offers extended warranty terms to all registered solar installations.

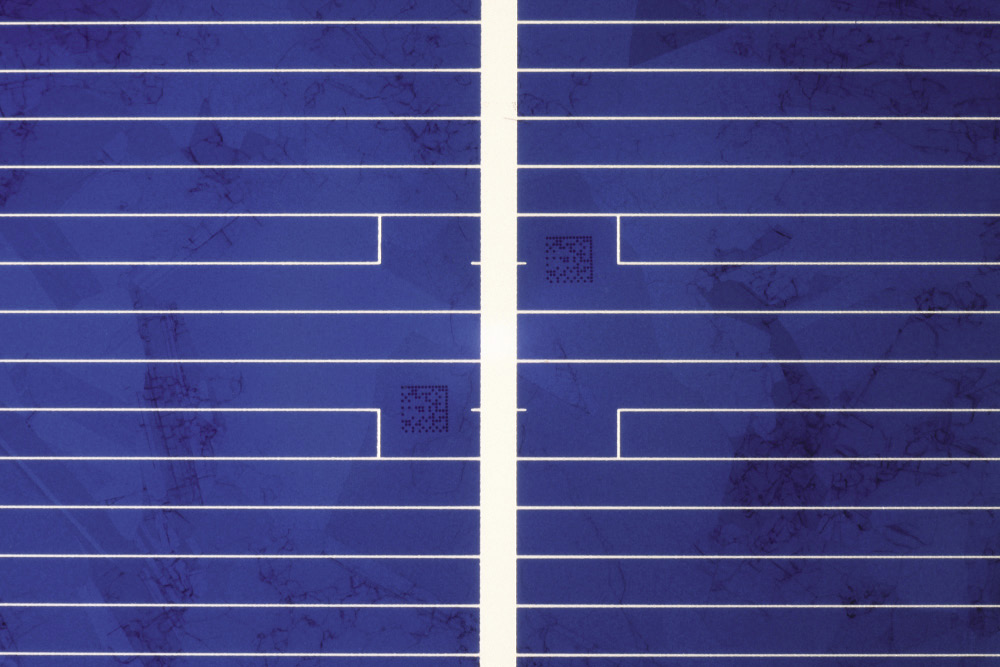

Another approach to combating counterfeits, taking things down to the cell level, can be seen with Korean manufacturer Hanwha Q Cells. The company deploys its patented Tra.Q process, where individual wafers are marked using a laser, and the marks can be read by a scanner. According to the company, such approaches have value beyond protection against counterfeiting. “Tra.Q gives each cell a unique fingerprint, which enables us to completely trace the entire manufacturing process for each individual solar cell – this includes the serial number, the date and location of production and even which material charge was used to make the cell,” says a Q Cells spokesperson. “We can thus better analyze errors and even make improvements as they arise.”

For Viamon, this fits in with a wider industry move toward quality assurance and establishing accountability across the supply chain, including in transit and installation. “Chip inside the shipment is an interesting new topic. That not only means counterfeiting but also controlling shipping routes, on-time deliveries, and the correct content of containers,” says Viamon general manager Oliver Strecke. “Often, the customer is so cost-sensitive that copy-protected chips are not easy to establish in every module. I believe that using random samples of a whole shipment could be a worthy solution.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I bought a solar panel from [an online shopping site] that was poor quality and not what watts l ordered beware of them it was supposed to be a 1000 watt panel but it wasn’t very small