Researchers from Sweden's Mälardalen University have come up with a new rotating PV array concept for vertical deployment on the cooling towers of thermal power plants.

The proposed model is defined an “adaptive celestial motion-based solar PV system” that can rotate around its own axis and revolve around the cooling tower to follow the sun. The scientists selected three thermal power plants with cooling towers in China for a case study.

Surface area

The group explained that the best balance between power output and energy-harvesting efficiency is achieved when only one-sixth of the outer surface of the cooling tower is covered with PV modules, at a tilt angle of between 60° and 90°.

“In terms of elevation angle of solar panels, the studied system can always keep the solar panels as perpendicular to the solar rays due to the ability of rotating around its own axis,” it stated, adding that the area of space between the solar panels should account for 20% of the total solar array area.

For example, at the Wujing Thermal Power Plant, the solar array would occupy a total surface of 4,676.8 meters squared, assuming the deployment of 2,405 panels with power output of 365 W.

Four designs

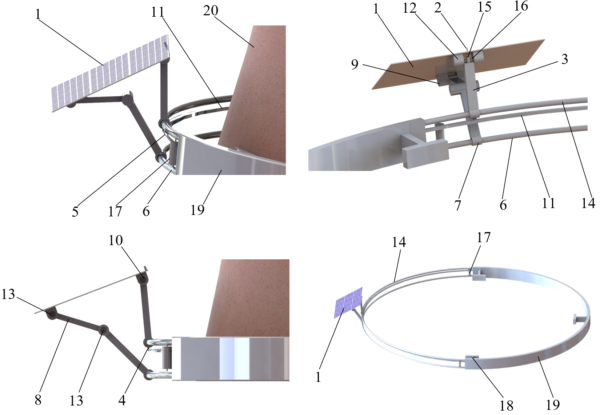

Four different PV system configurations were proposed for such projects: with fixed solar panels on the cooling tower with an azimuth angle of 0° and a tilt angle of 15; with panels rotating on their own axis to adjust the tilt angle with a fixed azimuth angle of 0°; with modules revolving around the cooling tower to adjust the azimuth with a fixed tilt angle of 15°; and with rotating and revolving panels collaboratively adjusting the tilt angle and the azimuth angle.

Image: Mälardalen University

“This is totally new design which integrates the existing … facilities without negative impacts of land-use and also close to the electricity demand sides,” research coordinator Jinyue Yan told pv magazine. “I had this idea one year ago and we have not seen a similar system in the market.”

Cost concerns

Projects developed with these technologies at the three Chinese thermal power plants have capacities of 1.76 MW (Wujing), 3.52 MW (Datong), and 1.82 MW (Hami).

“The estimated hard cost is about 1 USD/W,” Yan said. “We estimate the costs of the installation is similar as roof PV power generation without costs for the land occupation. As system can be rotated, the efficiency can be higher than the fixed roof top PV power generation.”

The annual power yield and total power generation during a project’s lifetime is also higher with the rotating and revolving configuration, the scientists claim. The best return on investment, however, is ensured by the revolving configuration.

“The levelized cost of energy (LCOE) of the proposed photovoltaic system with the ‘fixed' or ‘revolving' configurations is lower than the local benchmark price of photovoltaic electricity in the three studied power plants, indicating the possibility of reaching grid parity,” Yan stated.

Cooling towers

Such projects are also cheaper to install than ground-mounted arrays or rooftop PV plants due to their proximity to the power grid.

“In China, there are more than 2,000 cooling towers of thermal power plants – thus, we predict that the cooling tower-based PVs has huge potential for bringing considerable economic and energy benefits in the future,” the research group said.

They describe their proposed model in A celestial motion-based solar photovoltaics installed on a cooling tower, recently published in Energy Conversion and Management and on the ScienceDirect website.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

One thing to take account of is the static and dynamic loads which will be placed on the tower, and the impact of the panels on aerodynamics. Probably not a good idea to deploy this technology too close to the coast in areas exposed to typhoons! Probably should make models and carry out wind tunnel tests to determine the effects under a variety of conditions!