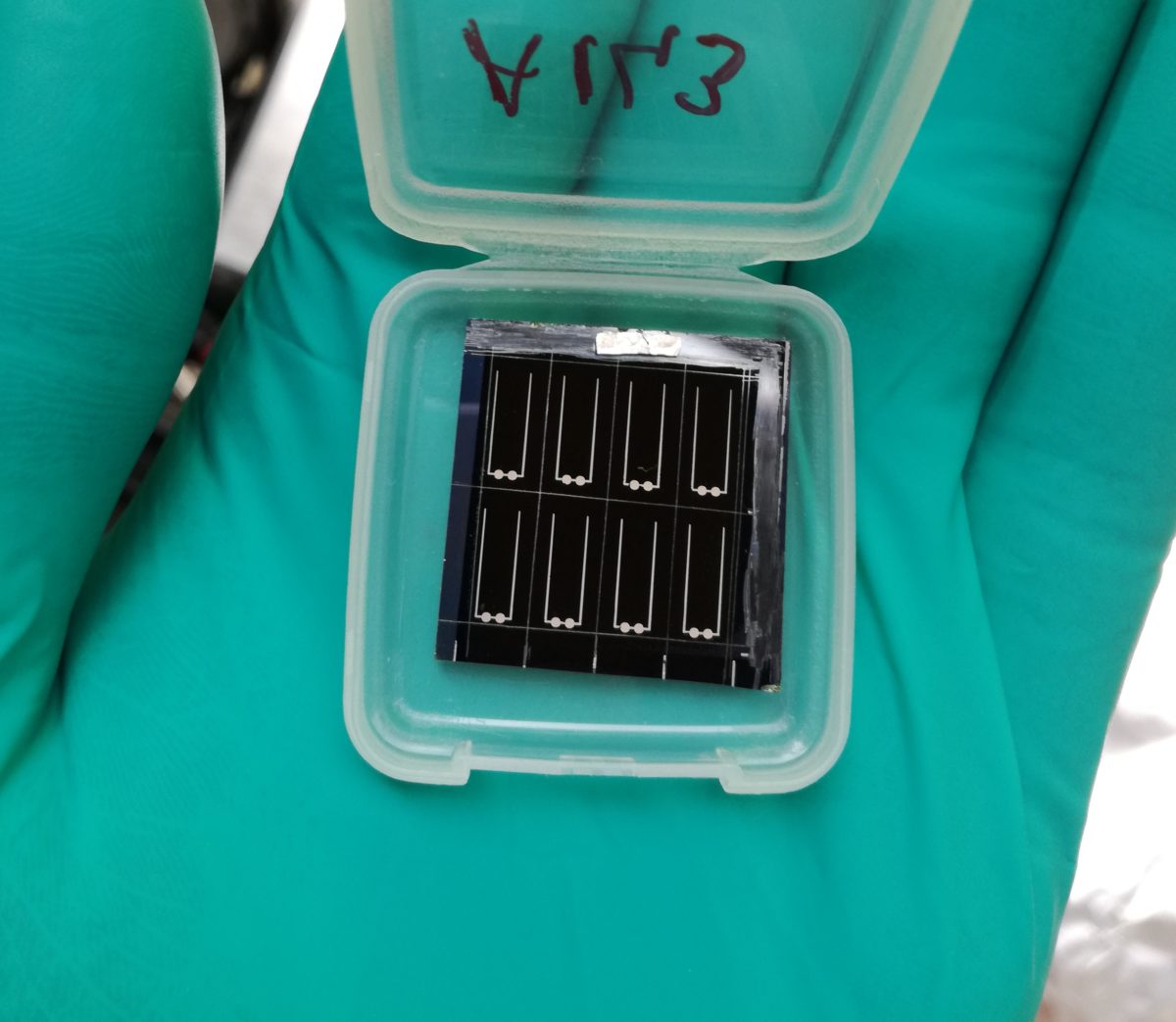

A group of German scientists has created a new process for the formation of a phase pure kesterite Cu2ZnSnSe4 (CZTSe), to facilitate the development of a solar cell with an efficiency of more than 10%.

The researchers describe the process in Reaction Pathway for Efficient Cu2ZnSnSe4 Solar Cells from Alloyed Cu-Sn Precursor via a Cu‐Rich Selenization Stage, published in RRL Solar. The method offers a different way to control the composition and quality of the grown material.

The usual process for growing the kesterite is the selenization of stacked elemental metallic layers made of copper (Cu), tin (Sn) and zinc (Zn). This process, which also involves a reaction route containing binary selenides, must be performed at annealing temperatures of 500 C to 550 C, but that makes the reaction pathway prone to tin losses.

The proposed process, instead, is based on stacked elemental and alloyed precursors and a Zn/Cu-Sn/Zn precursor structure. According to the research team, stacked elemental-alloy layers (SEAL) precursor consisting of Cu–Sn alloy and elemental Zn layers offer better process control due to their advantages, such as improved material homogeneity and the suppression of the aforementioned tin losses.

“We show that starting with the SEAL precursor and selenization without alloy segregation provide a route of kesterite CZTSe formation without X-ray fluorescence detectable Sn loss,” the scientists wrote. “As a consequence of the Cu‐rich starting composition and bonding of Sn in the alloy structure, the formation and subsequent evaporation of SnSe2−x phases in the reaction are significantly reduced, preventing Sn loss from the layer during the selenization process.”

The proposed process further shows the possibility of an in-process composition shift in the sample from initially Cu-rich to finally Cu-poor. “This allows for the design of a defined reaction and composition pathway throughout the process,which could be a novel approach for reaching higher solar cell efficiencies, as known for high-efficiency CIGSe solar cell processing,” the scientists further explained.

Kesterite is one of the most promising light absorber material candidates for potential use in lower-cost thin-film solar cells. Kesterites are comprised of common elements, such as copper, tin, zinc and selenium and, unlike copper indium gallium selenide (CIGS) compounds, no supply bottlenecks are expected in the future. The latter, however, is currently able to provide cell efficiencies close to 20%, while kesterites have thus far achieved efficiencies of just 12.6%.

In December, Estonian researchers announced the development of a new monograin powder technology made of microcrystals, which can form parallel connected miniature kesterite solar cells in a large module. By replacing copper with silver in the absorber material, the researchers were able to achieve an efficiency of 8.7%.

In August 2018, Australian researchers achieved a 10% efficiency rate for a cell based on copper zinc tin sulfide, or sulfide kesterite. The world record for such cells is 12.6%, achieved by Japanese thin-film producer Solar Frontier in 2013.

Last year, researchers from Helmholtz-Zentrum Berlin revealed that they were trying to replace tin with germanium in the development of kesterite solar cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.