Scientists at the Pacific Northwest National Laboratory (PNNL) in the U.S. have used carbon nanotubes to overcome some of the problems inherent in developing silicon anodes for lithium-ion batteries.

Silicon anodes have the potential to markedly increase battery energy density if used as an alternative to the graphite anodes widely deployed in commercial batteries today.

One of the issues with silicon is that it tends to expand greatly, sometimes by as much as 400%, as it forms alloys with lithium. Expansion leads to a range of performance degrading effects. Although scientists at Rice University this year demonstrated how working with porous silicon could provide an answer, the resulting anodes lacked mechanical strength and had to have their capacity limited well below maximum potential – albeit still far above graphite – to minimize stress on the electrode.

Carbon nanotubes

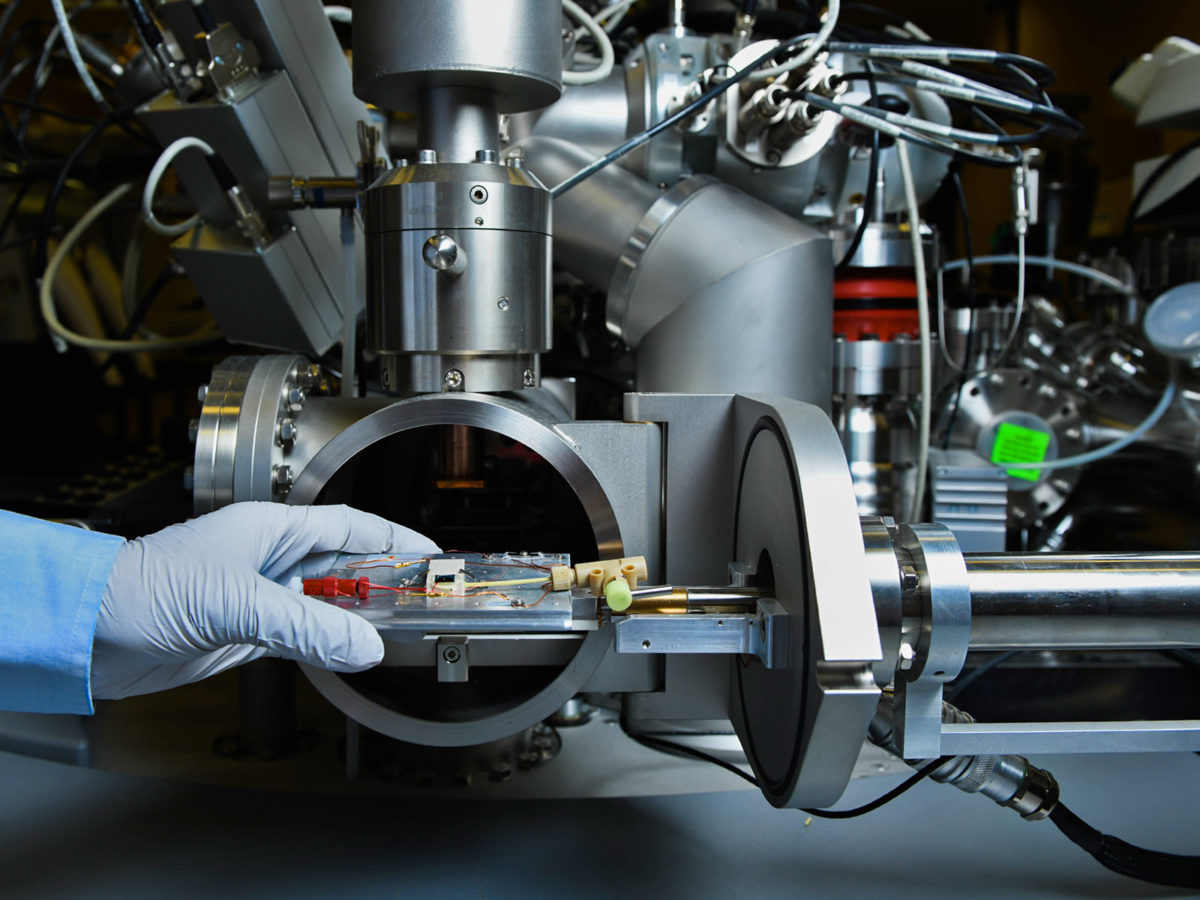

The PNNL group turned to carbon nanotubes which they were able to incorporate into a silicon anode. Using thermite reduction, the group fabricated carbon nanotube-silicon microspheres – small round particles able to absorb enough of the silicon particle expansion to limit it to around 30% on full lithiation. The anodes also exhibited excellent mechanical strength and were able to withstand 200 Megapascals of pressure.

The researchers fabricated several silicon electrode designs based on the concept, which are described in the paper Hierarchical porous silicon structures with extraordinary mechanical strength as high-performance lithium-ion battery anodes, published in Nature Communications. An anode with a “yarn ball like” structure of carbon nanotubes, silicon and carbon, delivered reversible capacity of around 1500 millamp-hours per gram (mAh g−1) and demonstrated 87% capacity retention over 1,500 cycles.

“On the basis of its excellent electrochemical performance, mechanical strength and structural integrity,” stated the paper, “CNT@Si [carbon nanotube-silicon]-based hierarchical porous nanostructure holds great promise for practical next-generation battery applications.”

The Pacific Northwest group said the next step would be to investigate scalable methods for producing the batteries, such as harnessing spray drying and mechanical condensation.

The researchers expect their work to influence other areas of battery design too. “The rational design of nanostructured battery materials and electrodes in this work,” the paper concluded, “also opens a new dimension in material design for other batteries.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.