From pv magazine USA

Two Chinese solar module manufacturers, Risen Energy and Trina Solar, have unveiled first-of-a kind 500 W, 50-cell PV modules.

How will the advent of 500 W PV modules change the solar industry?

“For applications where you have a lot of area, particularly commercial and especially utility scale, it’s really significant,” said Barry Cinnamon, CEO of solar and energy storage installer Cinnamon Energy Systems. “You could just use fewer modules – it reduces handling costs and overall balance-of-system costs go down.”

If fewer modules are needed to reach the capacity specifications of a project, costs will fall as such modules become economically viable. A significant project area that will see cost reductions is racking and trackers.

Cost savings

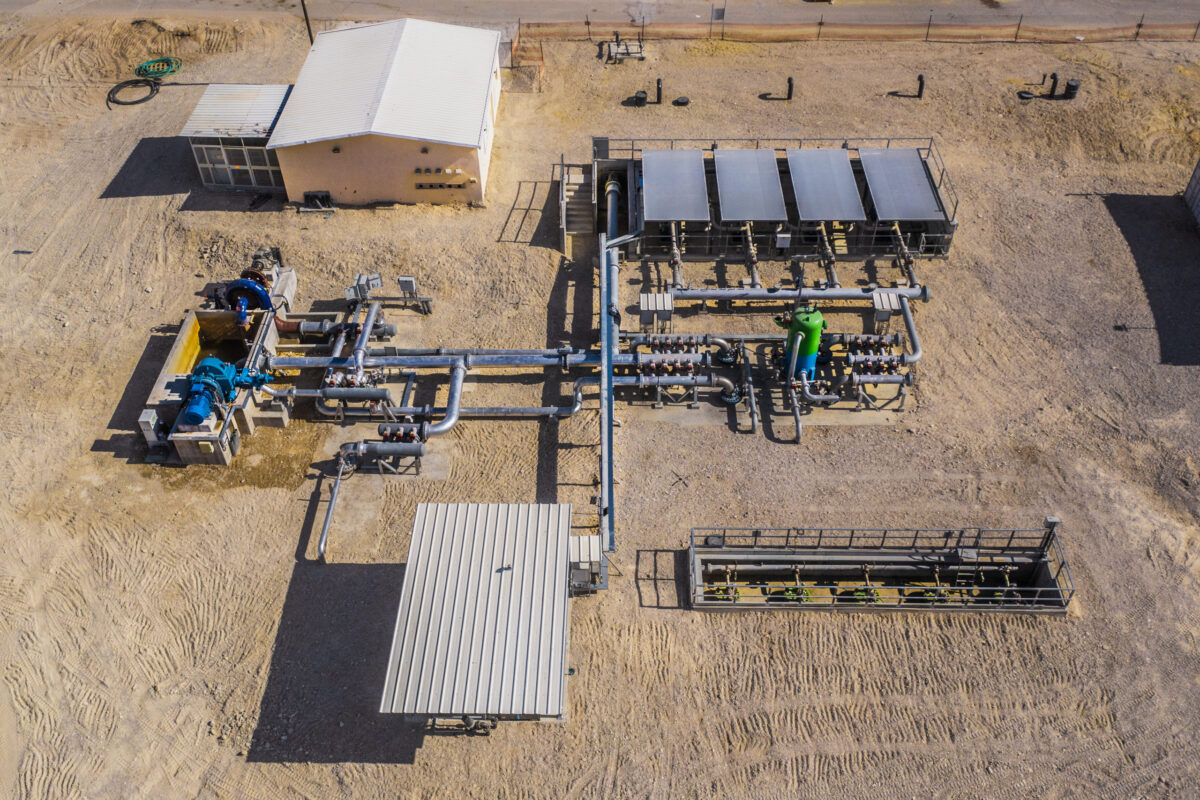

“It’s going to drive down the cost of racks and trackers per module,” said Matt Kesler, head of technology at OMCO Solar, an Arizona-based racking and fixed tilt tracking manufacturer. “It’ll reduce the cost per watt of installation labor. It’s also going to give a premium on racks and trackers that are designed for ergonomics. As these things get bigger they’re going to get heavier and wider. if there are features in the trackers and racks that assist in the placement of the modules, that’s going to have more value.”

The consensus among the installers interviewed by pv magazine was that the average module installed checks in at 380 W. This means that Trina and Risen’s panels deliver around 31% more power than the average installed panel. Cinnamon said that 10 years ago, the average module output was about 250 W.

As neat as that calculation is, these panels have a long way to go until they are industry standards, let alone benchmarks for the average installation.

“It takes about five years for the industry to change all of its assembly equipment to a new size,” said Cinnamon. “It’s a lot of work to buy new equipment because often it can’t be reprogrammed … We’re talking three to five years to change out all of that equipment.”

Trickle-down

“The most common sector is going to be C&I [commercial and industrial users],” said Jock Patterson of Fronius USA, an inverter company. “I see these on rooftops where space is limited and they want higher-efficiency modules. Large suppliers are going to feel the pressure to supply an inverter that’s 1,500 V. Those who aren’t providing that are going to feel like they’re missing out on those larger rooftop projects.”

The change is unlikely to be industry-wide, however. The residential solar market is expected to see little direct impact as the higher-power modules become commercially available – as roof space is usually limited, work spaces are angled and workers have to be able to carry the modules up ladders. Anything beyond the standard 1×1.6m, 60-cell module is too cumbersome.

The hope for residential installers pv magazine spoke with was that the technologies used to get modules to 500 W will eventually trickle down to their 60-cell, lower output brethren. That could mean residential installations would be able to take up less roofspace while providing more power, ultimately driving down balance-of-system costs.

Risen has claimed it could easily reach 600 Wp of output with a 60-cell panel.

This article was amended on 09/03/20 to reflect the new 500 W panels are 50-cell devices, not 72-cell modules as previously reported.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Wonderful!

It will very usefull for the the international PV market especially when there s lack or shortage of the roof area. Also it will be very useful for OF farms especially when the the land cost is very high.

What is the price of one 500 watt solar panel.

What are the sizes of 500wp SP?

Width- mm, Hole Centres- mm

Lenth- mm, Hole Centres- mm

Hole diametre- mm

Bolt Length- mm

More information please, I am interested.

Great news for the solar market reduce cost that’s what’s really needed.

The panels are made using M12 large silicon wafers with 210 mm side length and a power conversion efficiency of 20.2%. The module is built with 100 half cells interconnected with multi busbar technology resulting in larger than standard module dimensions of 2,205 x 1,123 x 40

How about it’s earthing system?

I am using 235 Watt panels. How much are the 500 Watt panels?

In India any dealer if need to purchase

THIS WILL BE A GREAT IMPROVEMENT IN ALL OUR SOLAR PROJECTS.. CONSIDERING SPACE..THANKS A MILLION

This is great, it will reduce the roof or ground area required and lower down cost as well.

Well this make solar panels cheaper

Hello

I’m indeed so impressed with the emergence of 500w module,

I hope it delivers beyond its expectations..

Good.

We need information.

Sorry to disappoint all euphoria.

These modules reach higher power-classes by getting larger!

The efficiency is (currently) even less than maximum state of the art.

The cells they use are 75% larger than the established one.

So no savings in area with this.

Sorry, but this article is poorly investigated, especially the second half.

For large scale PV (commercial free field) these larger modules might have an advantage,

simply because they are larger.

Hi there.

Thanks for your comment and it’s kind of a good news-bad news scenario. You are correct to point out the new, 500 W panels use larger cells but our reporter wrongly stated such modules use 72 cells when in fact they use only 50. That means they come in at around 210mm, making them smaller than conventional 72-cell panels. Thanks for pointing out the discrepancy, the copy above has now been amended.

I wonder if it isn’t about the wattage of the panels as much as it is the cost per watt installed. If a 500 watt panel is bigger and dramatically more expensive that current 350ish watt standard size panels, so what? Outside of niche applications, who cares? Show me a 425 watt panel of the current form factor that is half of today’s price per panel and I will talk to you about how it is shaping the solar industry.

Think you are quite correct.

Very informative post.

very useful information to all of us getting updated news of solar .. thanks for sharing keep updating news.