Chinese module suppliers continue to dominate the Australian PV market, with the exception of a handful of suppliers to “premium” rooftop solar customers. Germany’s AE Solar is looking to find a niche in Australia with both its European and Chinese-made modules, including its Supreme range, which features an innovative cell-level feature.

AE Solar’s Supreme modules include a “micro” bypass diode between individual cells, which it says means the modules are resistant to shading and are hot spot-free (HSF). The module series was introduced in Europe in 2018 and has been named a Top Innovation by pv magazine Australia’s German sister publication.

The AE Solar HSF technology goes one step further than optimizer or microinverter technology, managing the energy production at the individual cell rather than string of cells. In flash testing, this can be demonstrated to result in an increase of power output of up to 55% – in the event that two cells, in two separate cell strings are shaded.

The effect is demonstrated by a 2018 AE Solar video – replete with a Euro-house soundtrack. In the video a 275 W module is flashed four times alongside one of AE Solar’s Supreme module. The flasher output shows that the cell-level micro diodes maintain power output, even as an increasing number of cells, in different cell strings, are completed shaded.

Standard module

Unshaded 280 W

1 cell shaded in 1 cell string 187 W

3 cells shaded across 3 cell strings 85 W

6 cells shaded across 6 cell strings 6 W

AE Solar Supreme module

Unshaded 279 W

1 cell shaded in 1 cell string 270 W

3 cells shaded across 3 cell strings 250 W

6 cells shaded across 6 cell strings 221 W

Along with the additional power output when partial shading occurs, the micro bypass diodes also make the modules resistant to hotspot formation due to shading or heavy soiling. AE Solar says that cell temperatures will not exceed 85°C – preventing burnt cells and in extreme events, fires.

While AE Solar has not yet accredited its Supreme modules with the Clean Energy Council, it intends to do so and has gone through the process with 20 modules from its standard range.

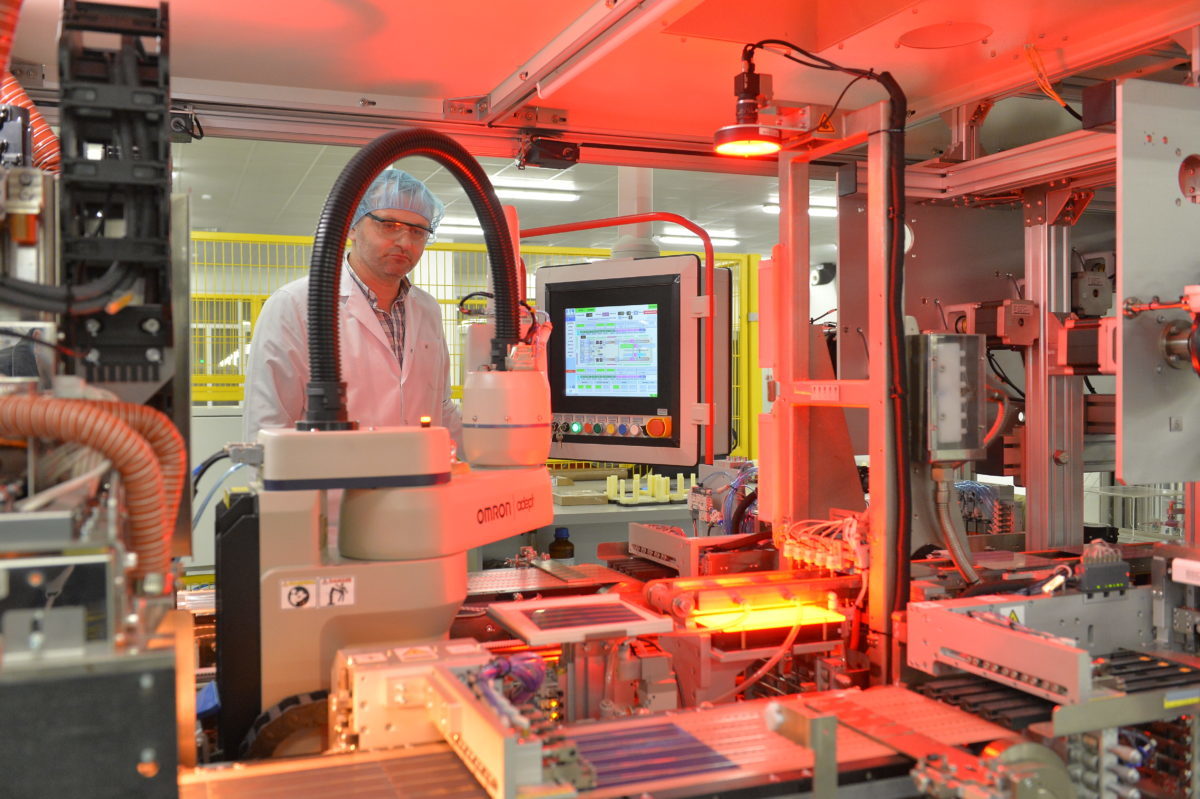

AE Solar has a production capacity of more than 1 GW, split between China and a new facility in Georgia. Some its EU module capacity is made with a 100% European bill of materials, to avoid tariffs in the U.S. market.

The company’s Shokhrukh Baratov says that the AE Solar is currently ramping up its new 16,000 m² module facility in Georgia.

“The factory is equipped with fully automated production lines provided mainly by an undisclosed equipment supplier, and has an annual capacity of 500 MW,” said Baratov. “The factory adds to AE Solar’s 525 MW manufacturing facility in Hongze, China, which has been running since 2009, raising the company’s annual production capacity to more than 1 GW. Even that may not be enough to keep up with demand, as AE Solar is planning to enter solar project development.”

AE Solar was founded in 2003. It reports that its engineers oversee production at its two facilities and product testing. It is targeting module shipments to Australia of between 50-80 MW in 2020.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.