Chinese module maker Trina Solar says its government-supported state key laboratory of PV science and technology has fabricated a 23.39% efficient PERC cell using standard manufacturing equipment and normal production processes.

Trina said it believes the device is the most efficient of its type to have had its performance confirmed by an ISO/IEC 17025-certified calibration laboratory.

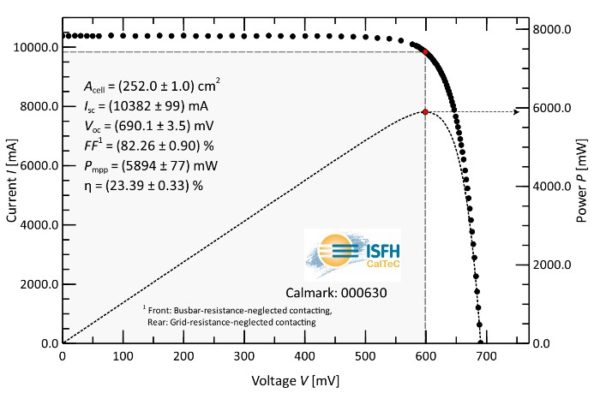

The bifacial 252cm2 cell, which features the manufacturer’s nine-busbar technology, was calibrated at ISFH CalTeC in Germany under full area illumination – with full front metallization taken into account – on a brass chuck in contact with the whole rear side, according to its developer.

Image: ISFH CalTeC Germany

Trina principal scientist Pietro P Altermatt said: “Each world record refers to a certain category, like ‘laboratory cell’ or ‘cast material’. There is no precisely defined category [for an] ‘industrial cell’ because equipment, in mass production, evolves over time and it is difficult to provide evidence of exactly how the reported cell was processed. Sometimes higher PERC cell efficiencies are announced but without stating details about metallization, or whether passivating contacts were used. This makes it difficult to assess progress in the field. This is why we are open about our manufacturing details.”

Trina VP and director of its state key laboratory Zhiqiang Feng said: “Our aim is to develop processes that can be transferred to production and, therefore, we decided to fabricate such champion PERC cells purely on equipment that is part of standard manufacturing lines, like metallization with standard screen printers.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

If you run a toy production line in a lab-like environment, you will get cells of different efficiencies. Picking the best to claim a record is fair enough assuming everybody does it. The real question is what’s the average.