Perovskites, it seems, have been on the brink of commercialization for a couple of years. While companies working with the technology have been able to pick up plenty of investment cash – and the research sector has a seemingly endless interest in the material – industry remains wary of the technology, and with good reason.

A paper published by scientists at the Massachusetts Institute of Technology takes a ‘techno-economic’ approach to analyzing market opportunities for perovskites. The study, Economically Sustainable Growth of Perovskite Photovoltaics Manufacturing, published in Joule, calculates an estimated $1 billion investment would be needed for perovskite modules to achieve a $0.40/W manufacturing cost – a price point likely to still leave perovskites struggling to compete with silicon PV.

“The largest modeled [factory] (1 GW/year) must sell for $0.72/W,” the paper states. “This value is around double the typical price currently obtained for photovoltaic modules in the grid-connected residential, commercial and utility PV markets.”

Alternative routes

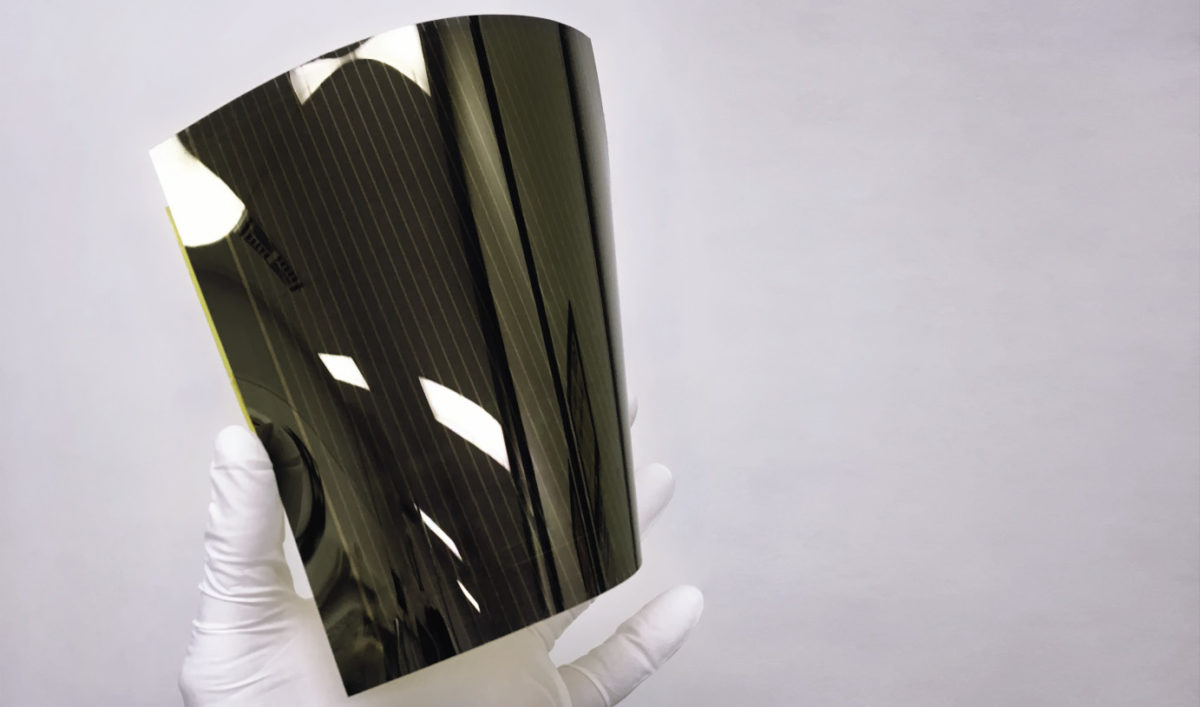

With that prohibitive investment cost in mind, the MIT researchers suggested alternative routes to market. They based their model on a ‘roll to roll’ manufacturing technique and noted certain of the materials required – particularly indium-tin-oxide film and unspecified ‘barrier foils – come at an high cost.

The model found, were such materials reduced to 70% of the model’s assumption, a roll-to-roll perovskite manufacturing line could operate profitably on a 202 MW scale with an initial investment of just $40 million. “This is a reasonable value for an existing large photovoltaics manufacturing company to raise and add a perovskite manufacturing line to their existing capacity,” stated the paper. “Although consideration must be given to ‘bankability’, i.e. the high risk of an unproven technology, especially one that faces a technology risk (stability) and a regulatory risk (lead content).”

Lead in c-Si modules

The researchers posited beginning with niche markets where higher costs per watt might be acceptable – such as in the building and vehicle-integrated PV segments, or in ‘internet of things’ applications. As a lower-risk option for scaling up, the MIT team suggested initial investment costs could be as little as $1 million.

If you can’t beat ’em…

The paper also develops models for tandem cell manufacturing, based on expanding silicon production lines to include perovskites and assuming a 2 GW silicon factory initially invested in 100 MW of perovskite-silicon tandem production.

Using such a model, the group outlined several scenarios where the addition of tandem cell capacity could allow a company to achieve a sustainable growth rate with margins of 15% or more, although cost-per-watt figures were not provided. The researchers also noted the model would be dependent on perovskite technology overcoming its remaining hurdles to large scale production.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I am a PhD student in Kenya. Working on Perovskite solar cell. These posts have been of benefits to me. Continue sending.