Scientists at South Korea’s University of Science and Technology are proposing a new manufacturing process which replaces EVA films with poly-dimethylsiloxane (PDMS) coatings for the encapsulation of PV modules.

The new process, which is based on a three-dimensional module structure, is intended to avoid the critical weaknesses of EVA films in terms of light trapping and chemical stability, such as browning problems and the cutting off of short-wavelength light, the researchers said.

Trapping short-wavelength light

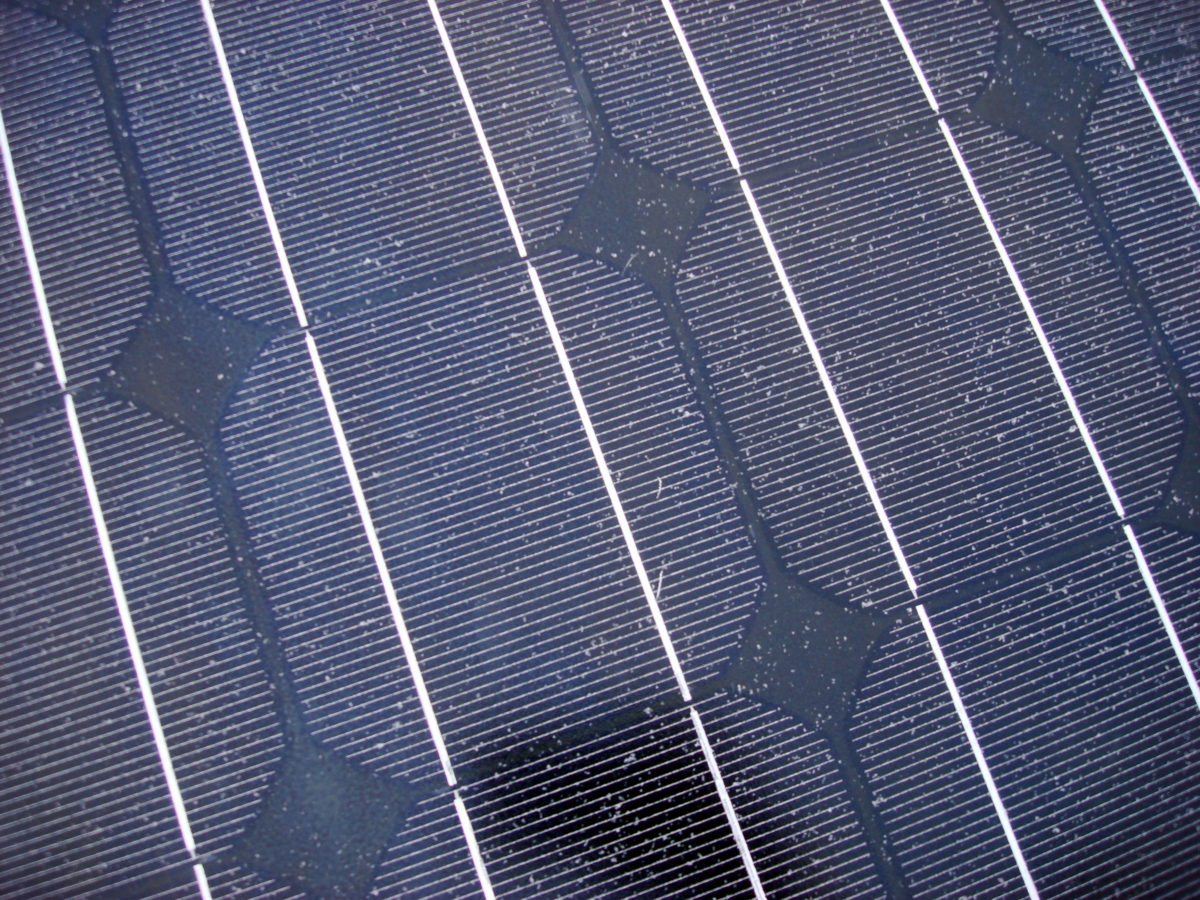

The technique was tested on four types of crystalline cells including polycrystalline and monocrystalline back surface field (BSF) devices and PERC and IBC mono cells. All the cells showed increased efficiency with the new coating for all values of angle of incidence, the researchers stated. “It is very interesting that the PDMS coating improves the efficiency in comparison with bare cells because it implies that the PDMS coating provides not just transmission of short-wavelength light – which is cut off by EVA encapsulation – but also induces an additional efficiency-enhanced mechanism for solar cells which was not well-known until now,” the paper noted.

According to the Korean team, efficiency enhancement for vertical illumination ranged from 1-1.5%, depending on cell type. “The short-wavelength, under-450 nm light produces more power by PDMS coating than the bare cells, regardless of the type of solar cell,” stated the study.

Yield increase

The scientists added, anti-reflective coatings in EVA films do not prevent the reflection of blue-colored, short-wavelength light. That light is, however, captured by the PDMS coating, according to its developers.

The researchers said the increase in electricity production in polycrystalline BSF cells manufactured with the new process was around 9%, while mono BSF cells registered a 7% rise. For mono PERC and IBC cells, power yield was raised 8% and 4.5%, respectively.

The research findings – presented in the paper Finding 10% hidden electricity in crystalline Si solar cells using PDMS coating and three‐dimensional cell arrays, and published in Progress in Photovoltaics – indicate up to 13.4% of ‘hidden electricity’ could be harvested in the PERC cells tested.

The researchers claim solar modules produced with the new technique may be better suitable for urban areas, which typically feature restricted installation space and high amounts of scattered light, compared with direct and vertical illumination.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

It looks as if most of the reported improvement comes from tweaking the cell geometry to capture more light at oblique angles, and only a small part from the change in encapsulation. The former has been in plain sight for years, and only missed by tunnel vision only looking at orthogonal conversion efficiency. In a fixed-tilt installation, this only reflects real life for a few hours in the year. The normal case is oblique illumination.

We beleve one day not to far in the near future we will be painting coatings that gnerate electricity