Scientists at Rice University have made a discovery they say could open a pathway to new, highly efficient battery design for grid storage, electric vehicles and other high energy applications.

The Houston-based researchers worked on replacing the graphite anodes commonly seen in commercial lithium-ion batteries with silicon alternatives. Silicon anodes have potentially much higher capacity than graphite but the uptick comes with a catch: Silicon expands by up to 400% as it alloys with lithium, leading loss of electrical contact and other potentially performance degrading issues.

Capacity boost

Graphite anodes typically have a capacity of around 350 milliamp-hours per gram (mAh/g), while silicon weighs in at around ten times that – 3,580 mAh/g. The Rice researchers found that by making the silicon porous, and limiting the anode’s capacity to 1,000 mAh/g, they were able to mitigate many of the negative effects.

“Maximum capacity puts a lot of stress on the material so this is a strategy to get capacity without the same degree of stress,” said Sibani Lisa Biswal, chemical and biomolecular engineer at Rice University. “One thousand milliamp-hours per gram is still a big jump.”

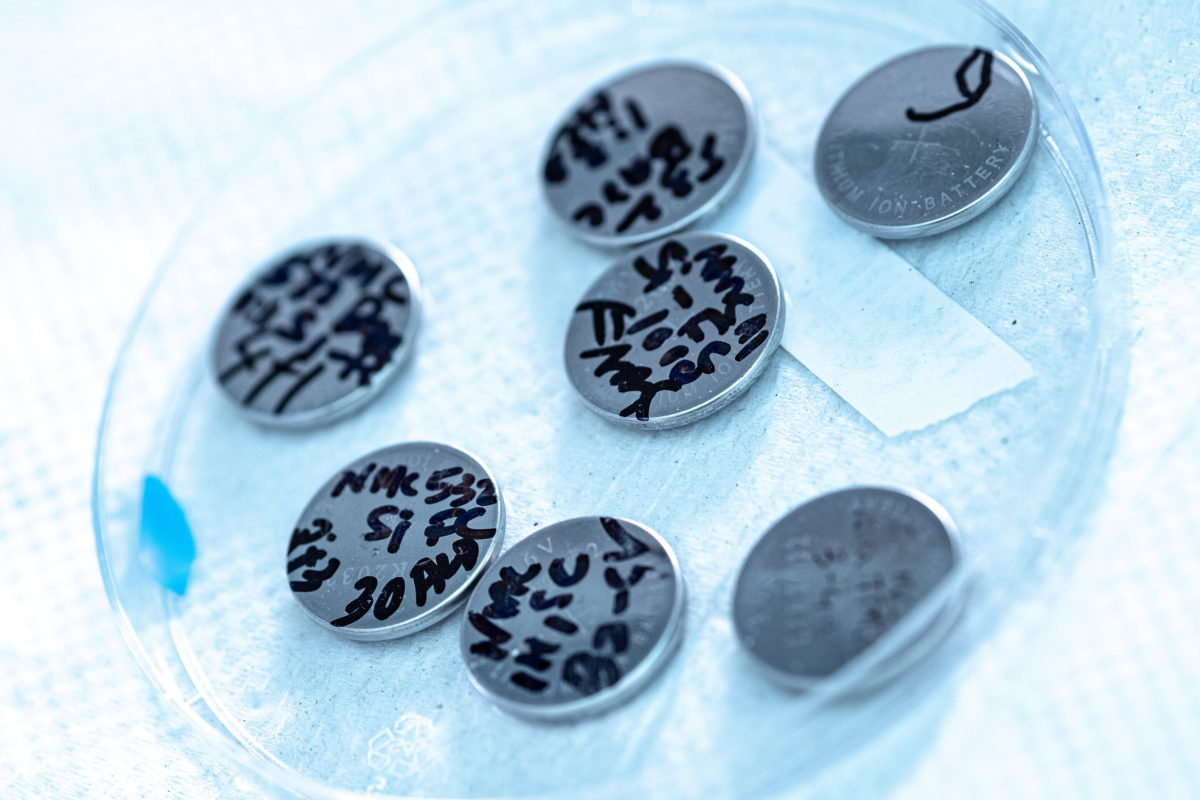

The group was able to combine the silicon anode with a nickel manganese cobalt oxide (NMC) cathode to form a full-cell lithium-ion battery which demonstrated stability at 1,000 mAh/g over 580 cycles. The device is described in the paper ALD-Modified LiNi0.33Mn0.33Co0.33O2 Paired with Macroporous Silicon for Lithium-Ion Batteries: An Investigation on Lithium Trapping, Resistance Rise, and Cycle-Life Performance, published in Applied Energy Materials.

Lithium trapping

Some of the NMC cathodes were coated in a three-nanometer thick layer of aluminum oxide, applied using atomic layer deposition. Investigation of the role of the coating led the group to document a previously unknown mechanism whereby lithium became trapped in the coating, limiting the number of times the battery could be charged and discharged.

However, the researchers noted, once the coating became saturated with lithium and unable to absorb any more the layer acted as a catalyst for fast transport to and from the cathode. “This lithium-trapping mechanism effectively protects the cathode by helping maintain a stable capacity and energy density for the full cells,” said Anulekha Haridas, a postdoctoral fellow at Rice.

The group said the discovery could open up a pathway toward the efficient use of silicon-NMC batteries and the researchers will now focus on reducing lithium-ion loss in the electrolyte and improving the cycle life of the batteries.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.