A group of scientists led by the Friedrich Alexander University of Erlangen Nürnberg (FAU) has set a new efficiency record for a prototype organic PV module.

The module measures 26.129 cm² and comprises 12 cells connected in series. The module has a fill factor of 95%, open circuit voltage of 9.978 V, and a conversion efficiency with respect to the module’s active area of 13.2%.

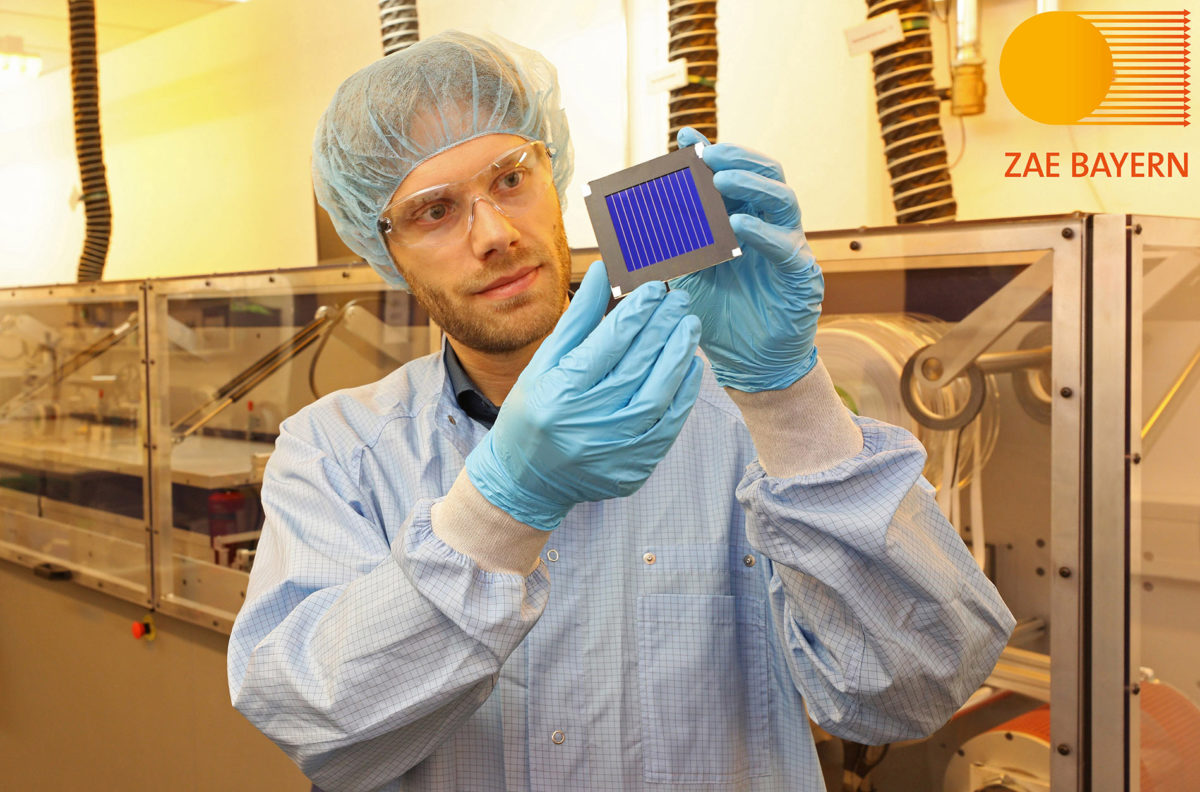

This achievement is the highest efficiency value ever reported for an organic PV module this size, a record confirmed by Fraunhofer ISE’s independent certification laboratory in Freiburg. The team comprised scientists from FAU, the Bavarian Center for Applied Energy Research, the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy, and South China University of Technology.

The result builds on the group’s previous achievement of 12.25% efficiency for a single organic PV cell measuring 1cm², announced in November 2018. According to FAU, the new 12.6% efficient prototype module represents a 30% increase over the previous world record of 9.7% for such a device.

The module was produced on a megawatt sized pilot production for thin film PV, part of the Energie Campus Nürnberg. “This milestone in organic semiconductor research shows that the latest performance developments with certified cell efficiencies of over 16 percent are not limited to the laboratory scale, but ready to be scaled up to the level of prototype modules,” explains FAU Professor Christoph Brabec.

FAU went on to note that module efficiency is always slightly lower than cell, due to inactive areas and resistance losses, noting that one of the key innovations to this research was minimizing inactive areas through a high resolution laser structuring process developed at the lab.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Does anyone know which materials this cell is made of?

Hi Dr. Cass,

I was wondering the same thing – I got the following answer from FAU as to the materials:

“The active layer consists of a bulk heterojunction formed by a semiconducting polymer called PM6 (PBDB-T-2F) and a non-fullerene acceptor called Y6 (BTP-4F). The layer was deposited by doctor blading of a solution of the two components in chloroform.”

In Chloroform? Any comment on how such a relatively low boiling point solvent was blade coated?

Will there be a publication following shortly?

Hi Richard,

You’d have to ask the University about this. You can contact them via https://www.fau.eu/