Solar cells based on copper zinc tin sulfide (CZTS) have attracted plenty of attention in recent years thanks to their reliance on cheap, abundant, non-toxic materials and potential for low cost production.

Thus far the efficiencies achieved with various combinations of such materials have lagged well behind the achievements of silicon and other technologies, with leading research groups struggling to surpass the 10% mark, even on smaller laboratory devices.

Now, a group of scientists at the Daegu Gyeongbuk Institute of Science and Technology (DGIST) in South Korea have achieved 11.4% efficiency with a flexible CZTS cell measuring 0.5cm². Though that fell to just over 8% efficiency when the cell was scaled up to 2cm², the researchers noted their cell design offered improvements in uniformity and provided possibilities to further enlarge the cell size.

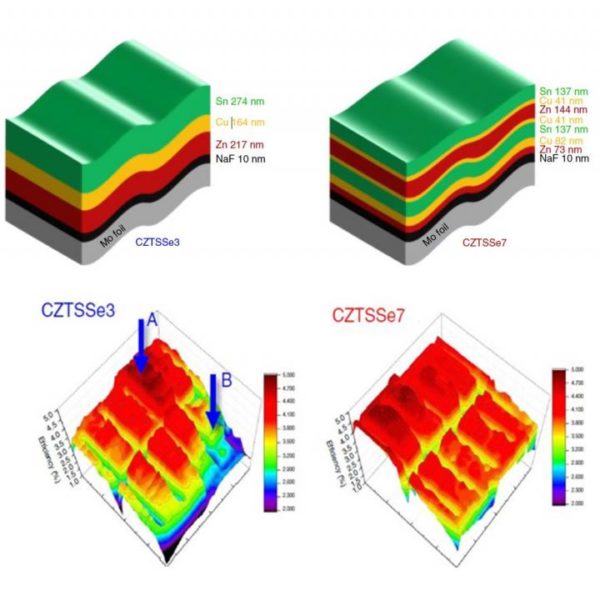

The device was described in the paper Flexible Cu2ZnSn(S,Se)4 solar cells with over 10% efficiency and methods of enlarging the cell area, published in Nature Communications. The group worked with a novel seven-layer thin film structure which they found offered superior performance to a more standard, three-layer film in terms of efficiency and large area uniformity.

“Our research achievement has presented ways to secure the uniformity of large-area process, which can cause issues in commercialization,” said the paper’s lead author Kee-Jeong Yang. “We will be able to advance the commercialization of [a] next-generation solar cell which is applicable in various fields, such as building outer walls.”

DGIST's results represent world record efficiencies for CZTS cells based on a flexible substrate, both at 0.5cm² and 2cm² cell size. The cells were fabricated using a sputtering process to apply the cell layers to a molybdenum foil substrate.

The efficiency record for a (non flexible) CZTS cell was set at 12.6% in 2013 by Japanese thin film specialist Solar Frontier. A group at the University of New South Wales has also made significant achievements with the technology. DGIST’s work with flexible substrates, however, could open up new use cases in lightweight and building-integrated PV applications if the efficiency can be scaled up further.

DGIST said it plans to open a research center for thin film solar cells. “As there is growing interest towards [the] environment, and resources are used [without limit] these days, it is a very meaningful achievement that we have developed a thin-film solar cell using widely available, eco-friendly materials,” said Jin-Kyu Kang, senior researcher at DGIST. “We plan to lead … future solar cell technology using widely available materials, and contribute to the development of [the] thin-film solar cell industry.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.