pv magazine: You developed a more realistic test sequence for mechanical load testing which simulates snow, then vibrations caused by wind, then daily temperature variation, then vibrations again. How do you implement this and what is difference to the standard tests included in the IEC [International Electrotechnical Commission] certification?

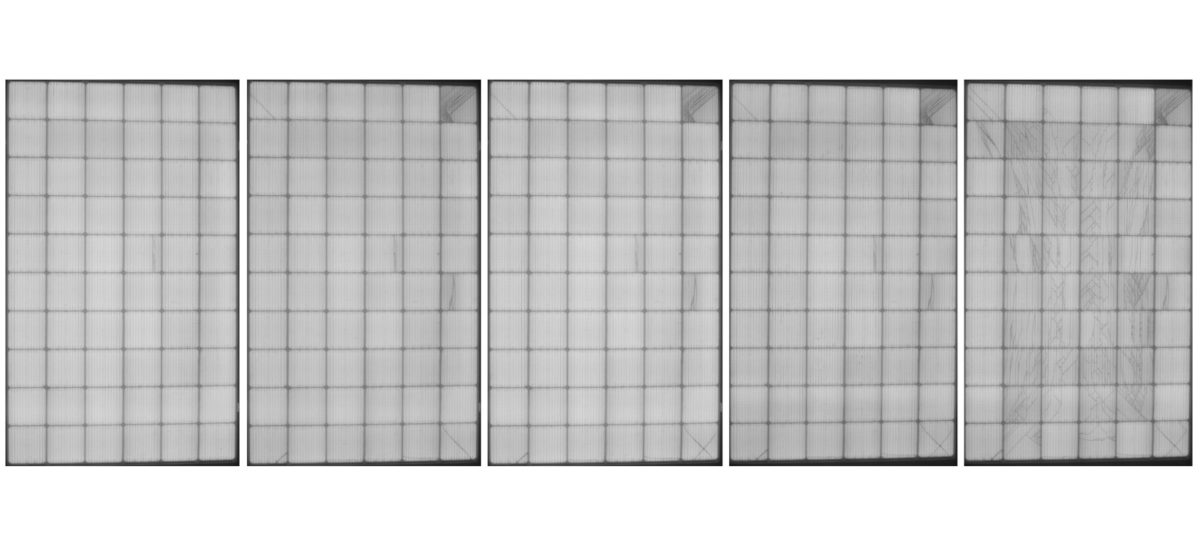

Eric Schneller, research scientist at the Florida Solar Energy Center institute of the University of Central Florida: The standard IEC sequence that aims to capture cell cracking involves cyclic mechanical loading followed by 50 thermal cycles and 10 humidity freeze cycles. We have implemented a modified sequence that uses this existing test sequence as the core, adding one step before and one step after. To start we use a large, front-side, static mechanical load to create cell cracks. The existing sequence then works to open up these cracks. Finally, an additional cyclic mechanical load is used to stress the cells after thermal exposure.

Why is the “simple” mechanical load test not sufficient?

The existing standard provides a reasonable minimum threshold of quality throughout the industry, but it remains unknown if this test adequately qualifies modules for the full 25-year operational lifetime that is expected. As with many of the other legs in the IEC 61215 standard, we believe there is an opportunity for a modified version that requires modules to withstand more severe testing conditions. Over the course of 25 years, modules are exposed to a wide range of thermal and mechanical stressors and we believe this modified sequence gets us closer to ensuring performance for the full operational lifetime. At the very least this sequence would be a valuable assessment for modules in locations where large mechanical loads are anticipated, such as large snow or wind loads.

Do you see more module failures when using your modified sequence?

In recent years it has become uncommon for typical module constructions to fail the existing mechanical durability testing sequence. This is certainly a positive trend for the industry, demonstrating overall improvement in module design and manufacturing processes. By adding additional steps to the qualification testing, there are certainly some modules that will fall below the 5% performance degradation threshold. As long as the qualification testing is reasonable and realistic, we think it is important to continue to push the industry to exceed prior benchmarks. Ultimately this will extend operational lifetimes of modules and continue to reduce the cost of solar energy.

pv magazine webinar

You investigated four module technologies and observed a clear trend as to which behaved better. Is this coincidental, due to the quality of the samples used, or do these results exhibit basic characteristics of the technologies? Do you have a theory about why you see these differences, and can you give us a clue?

In this work we investigated a few different module technologies and observed a wide range of responses to our modified testing sequence. It is certainly true that there is some random nature to cell cracking but it is clear from our results that the cell design, cell interconnection technology and packaging materials are critical in the overall mechanical durability of the modules. Cell and module manufacturing processes play an important role in initial crack susceptibility while the packaging and interconnection scheme are important to prevent crack opening or additional crack creation after thermal exposure.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.